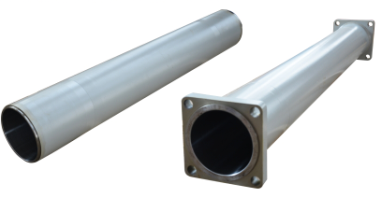

DELIVERY CYLINDER(SCHWING ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1775MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

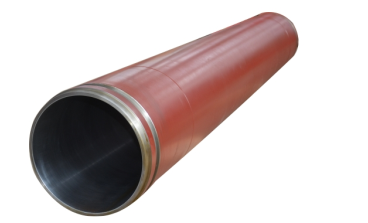

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: Are there any specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts. 1. Size and Compatibility: Ensure that the hydraulic filter or strainer you are installing is the correct size and compatible with the specific make and model of the concrete pump. Using the wrong size or incompatible filter can result in poor filtration or damage to the hydraulic system. 2. Location: The filter or strainer should be installed in a location that allows for easy access and maintenance. It should be positioned in a way that allows for proper filtration of the hydraulic fluid without obstructing the flow. 3. Mounting: The filter or strainer should be securely mounted to prevent any movement or vibration during operation. It is important to follow the manufacturer's instructions for proper mounting techniques and torque specifications. 4. Orientation: Pay attention to the recommended orientation of the filter or strainer. Some filters have specific flow direction requirements, and installing them incorrectly can affect their performance and efficiency. 5. Protection: Consider installing additional protection, such as a guard or shield, to prevent damage to the filter or strainer from external factors like debris or impacts. This can help prolong the lifespan and effectiveness of the filter. 6. Maintenance: Regularly inspect and clean the filter or strainer to ensure proper functioning. Follow the manufacturer's recommended maintenance schedule and procedures for replacement or cleaning to maintain optimal filtration efficiency. It is important to consult the manufacturer's instructions and guidelines for the specific hydraulic filter or strainer being installed, as they may have specific recommendations or requirements unique to their product.

- Q: How often should concrete pump control panels be inspected and replaced?

- Concrete pump control panels should be inspected regularly, ideally on a monthly basis, to ensure they are functioning properly and to identify any potential issues. However, the frequency of replacement will depend on the specific condition of the control panel, as well as the manufacturer's recommendations. If any signs of wear or malfunction are detected during the inspection, it may be necessary to replace the control panel sooner.

- Q: How often should concrete pump accumulators be inspected and replaced?

- Concrete pump accumulators should be inspected at least once a year to ensure their proper functioning and identify any potential issues. However, the frequency of replacement depends on various factors such as usage, maintenance, and the manufacturer's recommendations. It is recommended to consult the equipment manual or contact the manufacturer for specific guidelines on replacement intervals.

- Q: What is the concrete delivery pump?

- The utility model relates to a machine for continuously conveying concrete along a pipeline by utilizing pressure, which is mainly used for building, bridges and tunnels

- Q: What are the different types of concrete pump hydraulic pumps?

- There are several different types of hydraulic pumps that are commonly used in concrete pumps. 1. Gear pumps: Gear pumps are one of the most common types of hydraulic pumps used in concrete pumps. They consist of two meshing gears that push the hydraulic fluid from the inlet to the outlet. Gear pumps are known for their simplicity, durability, and reliability. 2. Piston pumps: Piston pumps are another popular type of hydraulic pump used in concrete pumps. They use reciprocating pistons to move the hydraulic fluid. Piston pumps are known for their high pressure capabilities and ability to handle heavy-duty applications. 3. Vane pumps: Vane pumps are often used in smaller concrete pumps or as auxiliary pumps in larger pumps. They use a series of vanes that rotate inside a housing to move the hydraulic fluid. Vane pumps are known for their compact size and efficiency. 4. Radial piston pumps: Radial piston pumps are typically used in high-pressure concrete pumps. They have multiple pistons arranged radially around a central shaft. The pistons move in and out to create the pumping action. Radial piston pumps are known for their high efficiency and power. 5. Axial piston pumps: Axial piston pumps are commonly used in large concrete pumps. They have multiple pistons arranged in a circular pattern around a central shaft. The pistons move in a linear motion to create the pumping action. Axial piston pumps are known for their high flow rates and pressure capabilities. Overall, the choice of hydraulic pump for a concrete pump depends on various factors such as the size of the pump, the desired pressure and flow rate, and the specific application requirements.

- Q: What are the indications of a faulty concrete pump hydraulic motor?

- Some indications of a faulty concrete pump hydraulic motor may include decreased pumping efficiency, irregular or inconsistent flow of concrete, unusual noises or vibrations, leaks or drips in the hydraulic system, excessive heat in the motor, or difficulty in starting or stopping the motor.

- Q: What is the purpose of a concrete pump wear plate?

- The purpose of a concrete pump wear plate is to protect the pumping system from wear and tear caused by the abrasive nature of concrete. Concrete pumps are used to transfer concrete from the mixer to the construction site, and during this process, the concrete passes through the wear plate. It acts as a barrier between the pumping system and the abrasive concrete, preventing direct contact and reducing the damage caused by the constant flow of concrete. The wear plate is typically made of durable materials such as hardened steel or tungsten carbide, which are resistant to the abrasive forces exerted by the concrete. By having a wear plate in place, the lifespan of the pumping system is significantly extended, reducing the need for frequent repairs and replacements. Overall, the purpose of a concrete pump wear plate is to ensure the efficient and reliable operation of concrete pumps by protecting and preserving the integrity of the pumping system.

- Q: How often should carbide wear plates be replaced in a concrete pump?

- The frequency at which carbide wear plates should be replaced in a concrete pump depends on several factors, including the type and quality of the plates, the intensity of usage, and the specific conditions in which the pump operates. Carbide wear plates are designed to endure heavy wear and tear caused by the abrasive nature of concrete. Generally, they have a longer lifespan compared to traditional steel wear plates. However, they are not completely immune to deterioration and will eventually wear down over time. A good rule of thumb is to regularly inspect the wear plates and monitor their condition. If the plates show signs of significant wear, such as visible cracks, excessive erosion, or reduced performance in terms of concrete flow, it is time to consider replacing them. In some cases, wear plates may need to be replaced annually, while in others, they may last several years. To prolong the lifespan of carbide wear plates, proper maintenance and care are essential. This includes regularly cleaning the plates, ensuring proper lubrication of the pump, and avoiding excessive pressure or abuse during operation. Regular maintenance can help to extend the lifespan of the wear plates and reduce the frequency of replacements. It is always recommended to consult the manufacturer's guidelines or seek advice from a professional concrete pump technician to determine the specific replacement interval for carbide wear plates in a particular pump model. They will have the expertise and knowledge to provide accurate recommendations based on the specific conditions and usage of the concrete pump.

- Q: What are the signs of a damaged or malfunctioning electric motor?

- A damaged or malfunctioning electric motor can be identified by several signs. Firstly, unusual noises like grinding, squealing, or banging sounds are typically indicative of a problem. Such sounds may suggest that the motor's bearings are worn out or that there is an issue with its internal components. Secondly, excessive heat is another sign of a damaged electric motor. If the motor feels hotter than usual to the touch, it could indicate that the motor is working harder than it should or that there is an issue with its cooling system. Thirdly, a motor that frequently trips the circuit breaker or blows fuses clearly indicates a malfunction. This could be caused by an electrical fault within the motor or an overload due to a faulty component. Furthermore, a damaged electric motor may exhibit reduced performance or a noticeable decrease in power output. This can be observed as a decrease in speed or torque produced by the motor, or even a complete inability to start or function properly. Lastly, excessive vibration or shaking of the motor may indicate misalignment or a problem with its mounting. If not addressed promptly, this can lead to further damage. If any of these signs are noticed, it is recommended to immediately cease using the motor and seek the assistance of a qualified technician or electrician to diagnose and repair the issue. Ignoring or continuing to use a damaged motor can result in further damage and potentially dangerous situations.

- Q: How can one source reliable suppliers for concrete pump spare parts?

- One can source reliable suppliers for concrete pump spare parts by conducting thorough research, seeking recommendations from industry professionals, checking customer reviews and ratings, and verifying the supplier's credibility and experience in the market. Additionally, attending trade shows and exhibitions related to the construction industry can provide opportunities to connect with reputable suppliers.

Send your message to us

DELIVERY CYLINDER(SCHWING ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1775MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords