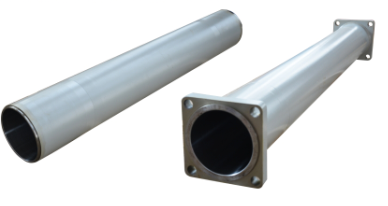

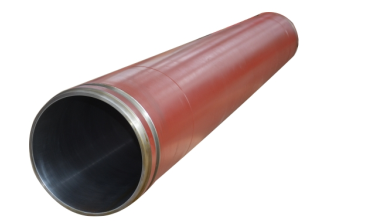

DELIVERY CYLINDER(PM ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:2305MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: Are there any specific recommendations for the inspection and testing of concrete pump spare parts?

- Concrete pump spare parts come with specific recommendations for inspection and testing. To begin with, it is essential to visually examine the spare parts for any damage, such as cracks, dents, or excessive wear. Carefully inspect the parts for any irregularities or abnormalities. Next, it is advised to conduct non-destructive testing (NDT) to guarantee the integrity and quality of the spare parts. NDT methods like ultrasonic testing, magnetic particle testing, or dye penetrant testing can be utilized to identify any hidden flaws or defects in the parts. These tests are beneficial in detecting potential issues that might impact the performance or safety of the concrete pump. Additionally, it is recommended to verify the dimensions and tolerances of the spare parts to ensure they adhere to the manufacturer's specifications. Precision measuring tools can be employed to compare the measurements with the required specifications. Any deviations should be documented and addressed accordingly. Furthermore, functional testing should be carried out to ensure that the spare parts are functioning as intended. This involves installing the parts in the concrete pump and conducting various tests to verify their functionality and performance. For instance, the pump's flow rate, pressure, and efficiency can be tested to ensure optimal performance. Lastly, it is of utmost importance to adhere to the manufacturer's guidelines and recommendations for inspecting and testing concrete pump spare parts. These guidelines provide specific instructions and procedures for accurately and safely inspecting and testing each type of spare part. It is crucial to consult the manufacturer's documentation and seek professional advice if necessary.

- Q: What kind of concrete pump truck?

- But the drawback is that the delivery speed is slow. Delivery height is better than vehicular pump. Among them, the more moderate is the car pump. But the advantage is that the arm pump can do, it can do, that is, when construction, need to install the pump ahead of time, relatively troublesome. But the relative pump speed and delivery height are higher

- Q: What is the function of a concrete pump hopper agitator shaft bearing?

- The function of a concrete pump hopper agitator shaft bearing is to provide support and facilitate smooth rotation of the agitator shaft, ensuring effective mixing of the concrete in the hopper.

- Q: What are the consequences of using substandard concrete pump spare parts?

- Using substandard concrete pump spare parts can have several consequences. Firstly, these parts may not fit properly or have the same level of durability as genuine parts, leading to frequent breakdowns and disruptions in construction projects. This can result in delays and increased costs for repairs or replacements. Secondly, substandard parts may compromise the overall performance and efficiency of the concrete pump. This can lead to decreased productivity, lower quality concrete output, and potential safety hazards for workers. Moreover, using low-quality spare parts can void warranties and insurance coverage, leaving the project owner or contractor liable for any damages or accidents that may occur. Lastly, relying on substandard parts can negatively impact the reputation and credibility of the construction company. Clients may lose trust in their ability to deliver high-quality work, leading to a loss of business opportunities in the future. In conclusion, the consequences of using substandard concrete pump spare parts include increased costs, project delays, compromised performance, safety risks, legal liabilities, and damage to a company's reputation. Therefore, it is crucial to invest in genuine and high-quality spare parts to ensure smooth and efficient construction operations.

- Q: What are the skills of concrete pump?

- ) need vertical piping, along with the increase of height is the potential increase of concrete circumfluence trend, therefore should be the level of pipeline laying length between the concrete pump and vertical pipe, to ensure that there is sufficient to prevent backflow resistance of concrete

- Q: What is the washing process of the concrete pump pipe?

- Connect the reducing pipe and close the discharge door. Pour water directly into the hopper.

- Q: How can a malfunctioning hydraulic motor affect the pumping process?

- Various negative effects can occur in the pumping process due to a hydraulic motor malfunction. Firstly, there may be a decrease in pumping efficiency. The hydraulic motor is responsible for converting hydraulic energy into mechanical energy, which drives the pumping mechanism. If the motor is not functioning properly, it may not generate enough power to operate the pumping system effectively, resulting in a decrease in the volume or pressure of the pumped fluid. Moreover, an increase in energy consumption can be caused by a faulty hydraulic motor. Inefficient or faulty motor operation can lead to higher energy requirements to maintain the desired pumping rate. This increased energy consumption can result in higher operating costs and reduced overall system performance. Furthermore, irregular pumping or complete pump failure can occur as a result of a malfunctioning hydraulic motor. If the motor is not operating correctly, it may cause intermittent or inconsistent pumping, leading to fluctuations in the flow rate or pressure of the pumped fluid. In extreme cases, the motor may stop working entirely, resulting in a total loss of pumping functionality. Additionally, the entire pumping system may experience increased wear and tear due to a malfunctioning hydraulic motor. Improper motor operation can create excessive vibration or heat, leading to premature failure of other components such as seals, bearings, or pistons. This can result in frequent maintenance or repair requirements, leading to increased downtime and costs. In summary, the pumping process can be significantly affected by a malfunctioning hydraulic motor. This includes decreased efficiency, increased energy consumption, irregular pumping or complete pump failure, and increased wear and tear on the system. It is essential to regularly inspect and maintain hydraulic motors to ensure proper functioning and avoid potential issues that may disrupt the pumping process.

- Q: Are there any warranties or guarantees available for concrete pump spare parts?

- Yes, there are warranties and guarantees available for concrete pump spare parts. Many reputable manufacturers and suppliers offer warranties on their products, providing assurance of quality and performance. These warranties typically cover defects in materials or workmanship and may vary in duration and terms. It is advisable to inquire about the specific warranty or guarantee offered by the supplier before purchasing concrete pump spare parts.

- Q: Can concrete pump spare parts be inspected for dimensional accuracy before installation?

- Yes, concrete pump spare parts can be inspected for dimensional accuracy before installation. By conducting a thorough inspection, one can ensure that the spare parts meet the required specifications and will fit properly into the pump system. This pre-installation inspection helps prevent any potential issues or damage during operation, ensuring the efficient and reliable functioning of the concrete pump.

- Q: Can concrete pump spare parts be recycled or disposed of responsibly?

- Yes, concrete pump spare parts can be recycled or disposed of responsibly. Many components of concrete pump spare parts, such as steel and rubber, can be recycled. These materials can be separated and processed for reuse in other industries. Additionally, responsible disposal methods, such as proper waste management systems, can be employed to ensure that any non-recyclable parts are disposed of in an environmentally friendly manner. Overall, efforts can be made to minimize the environmental impact associated with concrete pump spare parts by adopting recycling and responsible disposal practices.

Send your message to us

DELIVERY CYLINDER(PM ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:2305MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords