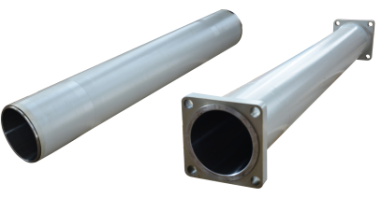

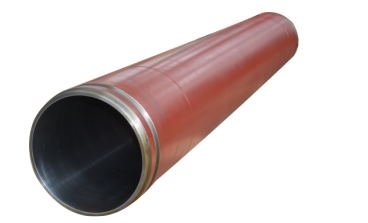

DELIVERY CYLINDER(SCHWING ) I.D.:DN250CR. THICKNESS :0.25MM-0.3MM LENGTH:2635MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: What are the signs of a malfunctioning hydraulic oil cooler?

- There are several signs that can indicate a malfunctioning hydraulic oil cooler. 1. Overheating: One of the most common signs is the engine or hydraulic system overheating. If the hydraulic oil cooler is not functioning properly, it may not be able to cool down the hydraulic fluid effectively, leading to increased temperatures in the system. This can result in reduced performance, increased wear and tear on components, and potential fluid breakdown. 2. Fluid Leaks: Another sign is the presence of hydraulic fluid leaks. A malfunctioning hydraulic oil cooler may have damaged or worn seals, gaskets, or hoses that can cause leaks. These leaks can be visible as fluid drips or puddles underneath the machinery or as oily residue on components. 3. Increased Noise: A malfunctioning hydraulic oil cooler may also cause increased noise levels in the hydraulic system. This can be due to air being introduced into the system, resulting in cavitation or aeration. These abnormal noises can indicate that the cooler is not functioning properly and may need to be inspected or replaced. 4. Elevated Temperatures: If you notice that the temperature gauge on your hydraulic system is consistently higher than normal, it could be a sign of a malfunctioning oil cooler. The cooler may not be able to effectively dissipate heat from the hydraulic fluid, causing temperatures to rise. This can lead to reduced efficiency, increased wear on components, and potential system failures. 5. Reduced Performance: A malfunctioning hydraulic oil cooler can also lead to reduced overall performance of the machinery or equipment. This can manifest as slower operation, decreased power output, or reduced hydraulic system response. If you notice a decrease in performance, it is worth checking the oil cooler for any issues. If you observe any of these signs, it is important to address the issue promptly. Continuing to operate machinery with a malfunctioning hydraulic oil cooler can lead to further damage, increased downtime, and potentially costly repairs. Consulting with a qualified technician or hydraulic specialist is recommended to diagnose and resolve any issues with the oil cooler.

- Q: Are there any specific guidelines for the installation of hopper components or agitators in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of hopper components or agitators in concrete pump spare parts. These guidelines typically include instructions on proper alignment, securing of bolts, lubrication, and ensuring all components are properly connected. It is important to follow these guidelines to ensure safe and efficient operation of the concrete pump.

- Q: What are the signs of a damaged concrete pump cylinder?

- There are several signs that can indicate a damaged concrete pump cylinder. One of the most obvious signs is leakage of hydraulic fluid from the cylinder. If you notice any fluid dripping or pooling around the cylinder, it could be an indication of a damaged seal or piston. Another sign of a damaged concrete pump cylinder is abnormal noise during operation. If you hear any unusual clanking, grinding, or knocking sounds coming from the pump, it could be a result of a damaged cylinder. This can be caused by a variety of issues such as a bent piston rod, worn out bearings, or misalignment of components. Decreased pumping efficiency is also a common sign of a damaged cylinder. If you notice that the pump is not delivering concrete as effectively as it used to, it could be due to a damaged cylinder. This can result in reduced output, slower pumping speed, or even complete failure to pump concrete. Visual inspection can also help identify signs of a damaged cylinder. Look for any visible cracks, dents, or deformations on the cylinder body. Additionally, check for any signs of excessive wear on the piston or piston rod, such as scratches or grooves. Lastly, if you experience frequent breakdowns or malfunctions with the concrete pump, it could be an indication of a damaged cylinder. Constant repairs or failures can be a result of underlying issues with the cylinder, such as fatigue, corrosion, or improper maintenance. If you notice any of these signs, it is important to address the issue promptly. Continuing to operate a concrete pump with a damaged cylinder can lead to further damage, increased repair costs, and potential safety hazards. It is recommended to consult a professional technician or manufacturer to assess and repair the damaged cylinder.

- Q: What are the indications of a damaged concrete pump boom?

- There are several indications that can point to a damaged concrete pump boom. These indications can include: 1. Visual damage: One of the most obvious signs of a damaged concrete pump boom is visible physical damage. This can include cracks, dents, or deformities in the boom structure. Any signs of structural damage should be taken seriously as they can compromise the integrity of the boom. 2. Leaks: Another indication of a damaged boom is the presence of leaks. If you notice hydraulic fluid or water leaking from the boom, it could be a sign of a damaged hose or fitting. Leaks can not only affect the performance of the pump but also pose a safety risk to the operator and those working around the equipment. 3. Misalignment: A damaged boom may also exhibit misalignment issues. If the boom is not straight or appears to be bent at an odd angle, it could indicate damage. Misalignment can affect the accuracy and efficiency of concrete placement, potentially leading to uneven or improper pouring. 4. Unusual noises: Strange or excessive noises during operation can be a sign of a damaged boom. Rattling, grinding, or squealing sounds can indicate loose or worn-out components, such as pins, bushings, or bearings. These noises should not be ignored, as they could worsen if not addressed promptly. 5. Reduced performance: A damaged boom may also result in reduced performance. If you notice a decrease in pumping capacity or difficulties in controlling the boom's movement, it could be an indication of damage. Poor performance can be caused by various issues, including hydraulic system problems, structural damage, or worn-out parts. In conclusion, it is crucial to regularly inspect and maintain concrete pump booms to identify any indications of damage. Promptly addressing these issues is essential to ensure the safety of operators, prevent further damage, and maintain the efficiency and performance of the equipment.

- Q: What are the functions of concrete pump truck?

- According to the structure and use of divided into drag type concrete pump, truck pump and pump car, according to the power type is divided into electric concrete pump and diesel power concrete pump

- Q: What are the key factors to consider when purchasing concrete pump spare parts?

- To make the correct choice when buying spare parts for your concrete pump, it is important to take into account several significant factors. These factors include: 1. Quality is of utmost importance as it directly affects the performance and lifespan of your concrete pump. To ensure durability and reliability, opt for spare parts made from high-quality materials and reputable brands. 2. Compatibility is essential, so make sure the spare parts you purchase are suitable for your specific concrete pump model. Check the specifications and consult with experts or the manufacturer to avoid any compatibility issues. 3. Cost-effectiveness should be considered, but it should not be the sole determining factor. Strive to strike a balance between price and quality to ensure long-term value for your investment. 4. Supplier reputation matters, so choose a trustworthy and reputable supplier with a proven track record of providing genuine and high-quality spare parts. Read customer reviews, verify certifications, and consider the supplier's industry experience. 5. Availability and lead time are crucial factors to prevent delays in your construction projects and minimize downtime. Ensure that the spare parts you need are readily available and can be delivered within a reasonable timeframe. 6. Warranty and after-sales support are important considerations. Check if the spare parts come with a warranty or guarantee, and also consider the availability of after-sales support and technical assistance for installation or maintenance queries. 7. Maintenance requirements should be taken into account. Look for spare parts that are easy to install, maintain, and repair as this can save you both time and money in the long run. By considering these key factors, you can make an informed decision and ensure that you purchase the appropriate spare parts for your concrete pump that align with your specific needs and requirements.

- Q: Which height of concrete pump is the most practical?

- The clay pump truck is modified on a truck chassis. It is mounted on the chassis with a power and motion device, a pump and a mixing device, a cloth arrangement, and other auxiliary devices

- Q: How can a faulty electric motor affect the pump's performance?

- A faulty electric motor can significantly impact the pump's performance. It may cause the motor to run at a slower speed, leading to reduced pumping capacity and lower flow rates. Additionally, a faulty motor can result in increased power consumption, decreased efficiency, and overheating issues. In severe cases, the motor may completely fail, causing the pump to stop working altogether. Therefore, addressing any issues with the electric motor promptly is crucial to maintaining optimal pump performance.

- Q: Do concrete pump spare parts come with a warranty?

- Yes, concrete pump spare parts do come with a warranty. The warranty period may vary depending on the manufacturer and the specific part being purchased. Generally, reputable manufacturers and suppliers offer warranties on their spare parts to provide assurance to customers about the quality and reliability of the product. It is important to carefully review the terms and conditions of the warranty to understand what is covered and for how long. If any defects or issues arise during the warranty period, customers can typically get a replacement or have the part repaired at no additional cost.

- Q: How often should hopper grate handles be inspected or replaced in a concrete pump?

- Regular inspections should be conducted on hopper grate handles in a concrete pump to identify any signs of wear and tear or damage. The frequency of these inspections and the need for replacement may vary depending on the equipment's usage and condition. It is suggested that the hopper grate handles be inspected at least once a month or after every 500 hours of operation, whichever occurs first. During the inspection, it is important to verify that the handles are firmly attached to the hopper grate and to examine them for any cracks, bends, or other structural problems. If any damage is detected, it is recommended to promptly replace the handles to prevent accidents or further harm to the equipment. It is also crucial to adhere to the manufacturer's guidelines and recommendations for the maintenance and replacement of hopper grate handles. By regularly inspecting and replacing the handles as necessary, the safe and efficient operation of the concrete pump can be ensured.

Send your message to us

DELIVERY CYLINDER(SCHWING ) I.D.:DN250CR. THICKNESS :0.25MM-0.3MM LENGTH:2635MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords