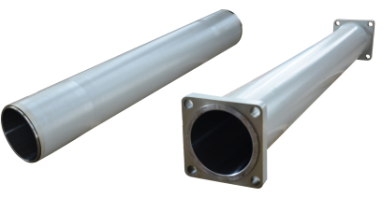

DELIVERY CYLINDER(PM ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:2320MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: What is the role of a concrete pump cylinder in a pumping system?

- The role of a concrete pump cylinder in a pumping system is to generate the necessary pressure and force required to transport concrete from the hopper or storage container to the desired location. The cylinder plays a crucial role in the pumping process by creating a reciprocating motion that helps in pushing the concrete through the pipeline. The concrete pump cylinder is typically connected to a piston, which moves back and forth inside the cylinder to create the pumping action. As the piston moves towards the outlet end of the cylinder, it creates a vacuum that sucks in the concrete from the hopper. When the piston moves in the opposite direction, it compresses the concrete and forces it out through the outlet valve, into the pipeline, and ultimately to the designated area. The size and design of the concrete pump cylinder depend on various factors such as the desired pumping capacity, the distance the concrete needs to be transported, and the viscosity of the concrete mix. It is essential for the cylinder to be strong and durable to withstand the high pressures and repetitive movements involved in the pumping process. In summary, the concrete pump cylinder is responsible for generating the necessary pressure and force to transport concrete efficiently and effectively. It forms the backbone of the pumping system, enabling the smooth and continuous flow of concrete from the hopper to the desired location.

- Q: What are the different types of concrete pump pistons?

- There are several different types of concrete pump pistons that are commonly used in the construction industry. These include: 1. Single-acting pistons: These pistons have one working side and are used in smaller concrete pumps. They push the concrete out of the cylinder during the forward stroke and rely on gravity to pull the piston back during the return stroke. 2. Double-acting pistons: These pistons have two working sides and are used in larger concrete pumps. They push the concrete out during the forward stroke and pull it back during the return stroke, increasing the efficiency of the pumping process. 3. S-tube pistons: These pistons are shaped like an S and are commonly used in trailer-mounted concrete pumps. They help to control the flow of concrete by directing it through a series of valves and pipes. 4. Rock valve pistons: These pistons are designed specifically for pumping concrete with larger aggregates. They have a rugged design that can handle the more abrasive nature of these types of materials. 5. Gate valve pistons: These pistons use a gate valve system to control the flow of concrete. They are commonly used in high-pressure applications and offer precise control over the amount of concrete being pumped. Overall, the type of concrete pump piston used will depend on the specific requirements of the construction project, including the size of the pump, the type of concrete being pumped, and the desired flow rate and pressure.

- Q: What are the common signs of wear and tear on concrete pump spare parts?

- The common signs of wear and tear on concrete pump spare parts can vary depending on the specific part in question. However, there are some general signs that can indicate when a concrete pump spare part is experiencing wear and tear. One common sign is visible damage or deterioration on the surface of the part. This can include cracks, chips, or dents on the outer layer of the spare part. These damages can occur due to regular use, exposure to harsh environmental conditions, or accidental impact during operation. Another sign is increased vibration or noise during operation. If a concrete pump spare part is experiencing wear and tear, it may start to produce unusual vibrations or noises that were not present when it was in good condition. This can be an indicator of internal damage or misalignment of the part, which can affect its overall performance and efficiency. Reduced performance or efficiency is also a common sign of wear and tear on concrete pump spare parts. If a part is experiencing wear and tear, it may not function as effectively as before, resulting in decreased pumping capacity, reduced flow rate, or inefficient operation. This can lead to delays in construction projects and increased maintenance costs. Additionally, increased maintenance and repair requirements can indicate wear and tear on concrete pump spare parts. If a part needs to be repaired or replaced more frequently than usual, it could be a sign that it is experiencing wear and tear. Regular inspections and maintenance can help identify potential issues early on and prevent further damage to the spare parts. In conclusion, signs of wear and tear on concrete pump spare parts can include visible damage, increased vibration or noise during operation, reduced performance or efficiency, and increased maintenance requirements. It is important to regularly inspect and maintain these spare parts to ensure their optimal performance and prolong their lifespan.

- Q: What is the role of a concrete pump hopper agitator blade?

- The role of a concrete pump hopper agitator blade is to mix and agitate the concrete mixture in the hopper, ensuring a consistent and homogeneous mixture. This helps to prevent the concrete from settling or becoming too thick, allowing for a smoother and more efficient pumping process.

- Q: How does a hopper vibrator prevent concrete blockages?

- A hopper vibrator prevents concrete blockages by vibrating the hopper, which helps to dislodge any stuck or compacted material, allowing it to flow freely through the hopper and preventing blockages.

- Q: How to deal with the blockage in the outlet of the distributing valve of the concrete pump?

- Pour the grout into the hopper, turn the pump in and out again and again, forcing the passage to open

- Q: How long do concrete pump rubber hoses typically last?

- Concrete pump rubber hoses typically last around 1 to 5 years, depending on various factors such as usage, maintenance, and environmental conditions.

- Q: Can I get spare parts for both single-cylinder and multi-cylinder concrete pumps?

- Spare parts for both single-cylinder and multi-cylinder concrete pumps are readily available. Various manufacturers and suppliers offer a wide range of spare parts for different concrete pump types, including single-cylinder and multi-cylinder models. These spare parts comprise hydraulic cylinders, pistons, seals, valves, hoses, and other crucial components that may require replacement due to wear and tear or damage. To ensure compatibility and availability, it is vital to contact the concrete pump's specific manufacturer or supplier and inquire about the spare parts suitable for your particular model.

- Q: How do concrete pump spare parts contribute to the overall performance of the pump?

- Concrete pump spare parts play a crucial role in maintaining the overall performance of the pump. These spare parts, such as pipes, hoses, valves, and wear plates, ensure the smooth functioning of the pump by minimizing downtime and improving efficiency. They help in maintaining a consistent flow of concrete, preventing clogs and leaks, and enhancing the accuracy of the pumping process. Regular maintenance and replacement of these spare parts not only extend the lifespan of the pump but also contribute to its reliable and optimal performance, ultimately leading to increased productivity and customer satisfaction.

- Q: What are the key considerations when purchasing spare parts for a concrete pump?

- When buying spare parts for a concrete pump, there are several important factors to think about. These factors include making sure that the spare parts are compatible with the concrete pump's make and model, checking their quality and reliability, ensuring their availability, and considering their cost-effectiveness. First and foremost, it is crucial to make sure that the spare parts you purchase are suitable for the concrete pump you have. Concrete pumps come in different makes and models, and each may have specific requirements for spare parts. Therefore, it is essential to carefully match the specifications and requirements of the concrete pump with the spare parts you buy to ensure proper functionality and performance. The quality and reliability of the spare parts are also important considerations. Investing in high-quality spare parts can have a significant impact on the efficiency and lifespan of the concrete pump. It is advisable to choose spare parts from reputable manufacturers or suppliers who have a proven track record of producing reliable products. Doing thorough research and reading customer reviews can help assess the quality and reliability of the spare parts. Availability is another crucial factor to consider when purchasing spare parts for a concrete pump. It is important to ensure that the spare parts you need are easily accessible, either from local suppliers or through efficient delivery channels. Delays in obtaining the necessary spare parts can result in extended downtime and increased costs. Therefore, it is recommended to choose suppliers with a reliable and efficient distribution network. Cost-effectiveness is also a key consideration when buying spare parts. While it is important to prioritize quality and reliability, it is equally important to find spare parts that offer good value for money. Comparing prices from different suppliers and considering the lifespan and potential maintenance costs of the spare parts can help make a cost-effective decision. It is crucial to strike a balance between cost and quality to ensure the best return on investment. In conclusion, when purchasing spare parts for a concrete pump, it is important to consider compatibility, quality, availability, and cost-effectiveness. By carefully evaluating these key factors, you can ensure that the spare parts you choose will meet the specific needs of your concrete pump, maintain its performance and reliability, and provide value for your money.

Send your message to us

DELIVERY CYLINDER(PM ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:2320MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords