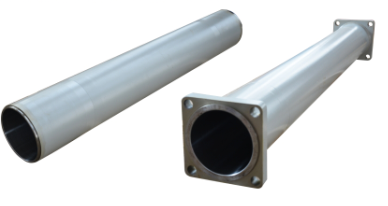

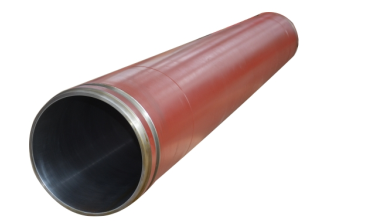

DELIVERY CYLINDER(SANY ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:2146MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: Are there any specific brands or manufacturers that are recommended for concrete pump spare parts?

- Yes, there are several brands and manufacturers that are recommended for concrete pump spare parts. Some of the most reputable ones include Schwing, Putzmeister, Sany, and Zoomlion. These brands have a proven track record for producing high-quality and durable spare parts that are compatible with various concrete pump models. It is always advised to consult with professionals or experts in the industry to determine the most suitable brand or manufacturer for specific concrete pump spare parts.

- Q: Are there any cost-effective alternatives to original concrete pump spare parts?

- Yes, there are cost-effective alternatives to original concrete pump spare parts available in the market. These alternatives, often referred to as aftermarket parts, are manufactured by third-party companies and offer similar quality and functionality as the original parts but at a lower price. However, it is crucial to ensure that the aftermarket parts are compatible with the specific make and model of the concrete pump to ensure proper fit and performance.

- Q: How often should concrete pump outriggers be inspected and maintained?

- Concrete pump outriggers should be inspected and maintained regularly, ideally before each use and at least once a month. This ensures their proper functioning and helps prevent any potential accidents or damage.

- Q: What is the name of the pump for concrete transportation?

- The power of the concrete pump truck engine power is transmitted to the hydraulic pump or rear axle through the power transfer case, push the piston to drive the hydraulic pump concrete pump. Then use the pump cloth on the rod and delivery pipe, the concrete delivery to a certain height and distance.

- Q: How can a faulty concrete pump cylinder affect the pumping process?

- The pumping process can be significantly impacted by a faulty cylinder in the concrete pump. The cylinder's role is crucial in the concrete pumping system as it generates the necessary pressure to push the concrete through the pipes and hoses. A decrease in pumping efficiency is one of the main issues caused by a faulty cylinder. If the cylinder is worn out or damaged, it may not generate sufficient pressure to effectively push the concrete. This can lead to a decrease in the pumping rate and overall productivity of the concrete pumping operation. Moreover, a faulty cylinder can cause irregular and inconsistent flow of concrete. This can result in blockages or clogs in the pipes, disrupting the pumping process. Removing these blockages can be time-consuming and costly, as it may require disassembling the pumping system to access and clear the blocked area. Additionally, leaks can occur in the pumping system due to a faulty cylinder. These leaks not only waste concrete but also reduce the overall pressure in the system, impacting the ability to pump the concrete to the desired location. Furthermore, leaks can create a messy worksite, posing safety risks for workers and potentially damaging surrounding structures. Furthermore, the risk of equipment failure is increased by a faulty cylinder. If the cylinder malfunctions or fails completely, it can cause the entire pumping system to shut down. This can result in significant downtime and delays in the concrete pouring process, leading to additional costs and potential penalties. In conclusion, a faulty concrete pump cylinder can have a significant impact on the pumping process by reducing efficiency, causing irregular flow, promoting leaks, and increasing the risk of equipment failure. To ensure smooth and efficient concrete pumping operations, it is essential to regularly maintain, inspect, and replace the cylinder in a timely manner.

- Q: How often should concrete pump seals be replaced?

- Concrete pump seals should be replaced every 500 to 800 hours of operation or whenever signs of wear, leakage, or decreased performance are observed.

- Q: What are the different types of concrete pump rubber hoses?

- There are several different types of concrete pump rubber hoses available, including wire-reinforced hoses, fabric-reinforced hoses, steel wire braided hoses, and composite hoses. These hoses are designed to withstand the high pressure and abrasive materials involved in pumping concrete, ensuring safe and efficient operations.

- Q: What are the different types of concrete pump hopper agitator motors?

- There are generally two types of concrete pump hopper agitator motors: electric motors and hydraulic motors. Electric motors are powered by electricity and are commonly used in smaller and portable concrete pumps. Hydraulic motors, on the other hand, are driven by hydraulic power generated by the concrete pump itself and are typically used in larger and stationary concrete pumps.

- Q: What are the key considerations when purchasing spare parts for a concrete pump?

- When purchasing spare parts for a concrete pump, there are several key considerations that need to be taken into account. These considerations include the compatibility of the spare parts with the specific make and model of the concrete pump, the quality and reliability of the spare parts, the availability of the spare parts, and the cost-effectiveness of the purchase. First and foremost, it is crucial to ensure that the spare parts being purchased are compatible with the concrete pump in question. Concrete pumps come in various makes and models, and each may have specific requirements in terms of spare parts. Therefore, it is essential to carefully match the specifications and requirements of the concrete pump with the spare parts being purchased to ensure proper functionality and performance. The quality and reliability of the spare parts are also vital considerations. Investing in high-quality spare parts can significantly impact the efficiency and longevity of the concrete pump. It is advisable to choose spare parts from reputable manufacturers or suppliers who have a proven track record of producing reliable products. Conducting thorough research and reading customer reviews can help in assessing the quality and reliability of the spare parts. Availability is another important factor to consider when purchasing spare parts for a concrete pump. It is essential to ensure that the spare parts needed are readily available, either from local suppliers or through efficient delivery channels. A delay in obtaining the necessary spare parts can lead to extended downtime and increased costs. Therefore, it is recommended to choose suppliers who have a reliable and efficient distribution network. Cost-effectiveness is also a key consideration when purchasing spare parts. While it is important to prioritize quality and reliability, it is equally important to find spare parts that offer good value for money. Comparing prices from different suppliers and considering the lifespan and potential maintenance costs of the spare parts can help in making a cost-effective decision. It is crucial to strike a balance between cost and quality to ensure the best return on investment. In conclusion, when purchasing spare parts for a concrete pump, it is important to consider compatibility, quality, availability, and cost-effectiveness. By carefully evaluating these key considerations, one can ensure that the spare parts chosen will meet the specific needs of the concrete pump, maintain its performance and reliability, and provide value for money.

- Q: Are there any specific safety considerations when using concrete pump spare parts?

- Concrete pump spare parts must be carefully considered for safety purposes. The first consideration is ensuring compatibility with the specific pump model. Using incompatible parts can lead to malfunctions, risking accidents and injuries. Proper training and knowledge are also crucial. Operators must be trained on installation, maintenance, and replacement of spare parts. They should also follow any safety precautions recommended by the manufacturer. Regular inspection of spare parts is important. Any signs of wear, damage, or deterioration should prompt immediate replacement to prevent accidents or equipment failure. Personal protective equipment (PPE) is essential when working with concrete pump spare parts. This may include goggles, gloves, hard hats, and steel-toed boots. PPE safeguards against hazards like debris, falls, or contact with hazardous substances. Adhering to local regulations and industry standards is advisable. These regulations may outline specific requirements for installation, operation, and maintenance of concrete pump spare parts. By adhering to these safety considerations, operators can minimize the risk of accidents, injuries, and equipment failure when using concrete pump spare parts.

Send your message to us

DELIVERY CYLINDER(SANY ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:2146MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords