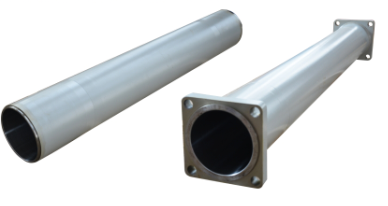

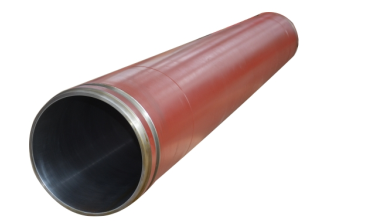

DELIVERY CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM LENGTH:1545MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: How often should concrete pump agitator motors be inspected and replaced?

- Concrete pump agitator motors should be inspected regularly to ensure they are functioning properly and to identify any potential issues before they become major problems. The frequency of inspections depends on various factors such as the workload and conditions in which the motor operates. However, a general guideline is to inspect the agitator motors at least once a year or after every 500 hours of operation, whichever comes first. In terms of replacement, it is essential to monitor the motor's performance closely. If there are any signs of motor failure, such as overheating, excessive noise, or decreased efficiency, it may be necessary to replace the motor sooner rather than later. Additionally, if the motor fails any inspections or tests, it should be replaced immediately to avoid any safety hazards or disruptions in the concrete pumping process. Ultimately, the key is to prioritize regular inspections and maintenance to extend the lifespan of the agitator motors and ensure they are operating at their optimal level. Following manufacturer guidelines, consulting with experts, and conducting routine checks will help determine the appropriate timing for inspections and replacements.

- Q: What are the indicators of a faulty concrete pump seal?

- There are several indicators that can suggest a faulty concrete pump seal. These include: 1. Leakage: One of the most obvious signs of a faulty seal is leakage of concrete or water around the seal area. If you notice any fluid seeping out from the seal, it is a clear indication of a problem. 2. Reduced pumping efficiency: A faulty seal can result in reduced pumping efficiency. If you notice that the concrete pump is not delivering the expected amount of concrete or is struggling to pump the material, it could be due to a seal issue. 3. Increased noise and vibration: A faulty seal can cause increased noise and vibration during the operation of the concrete pump. Unusual sounds or excessive vibration can indicate that the seal is not functioning properly, and further inspection may be required. 4. Premature wear and tear: If the seal is faulty, it can lead to premature wear and tear of other components in the pump system. This can be observed through the degradation of other parts such as gaskets, bearings, or pistons. Regular inspections can help identify such issues. 5. Inconsistent pressure: A faulty seal can result in inconsistent pressure while pumping concrete. If you notice variations in the pressure output or irregular flow of concrete, it may be a sign of a seal problem. 6. Excessive heat: Another indicator of a faulty seal is the generation of excessive heat in the seal area. If the seal is not functioning properly, it can cause friction and heat buildup, which can be felt or observed by touch. It is important to address any indication of a faulty concrete pump seal promptly to prevent further damage to the pump system and ensure the safety and efficiency of the operation. Consulting a professional or contacting the manufacturer for guidance and repair is recommended in such cases.

- Q: How does a hydraulic accumulator improve the performance of a concrete pump?

- To ensure a constant and reliable flow of concrete, a hydraulic accumulator is employed to enhance the performance of a concrete pump. The primary role of this hydraulic device is to store hydraulic energy in the form of pressurized fluid. In the case of a concrete pump, it stores and releases energy from the hydraulic system as needed during the pumping process. Efficiency and productivity in concrete pumping rely on a consistent flow of concrete. However, variations in demand or pressure fluctuations can pose challenges. This is where the hydraulic accumulator comes into play. By storing surplus hydraulic energy, the accumulator acts as a buffer, smoothing out any irregularities in the hydraulic system. When additional power is required, the stored energy is released, providing a boost to the hydraulic system. This ensures a continuous and steady flow of concrete, even during periods of high demand or pressure changes. Furthermore, hydraulic accumulators also contribute to reducing wear and tear on the pump components. By absorbing and dampening pressure shocks, they prevent sudden spikes and fluctuations from reaching the pump. This helps to extend the pump's lifespan and minimize the risk of breakdowns or damage. Overall, a hydraulic accumulator plays a critical role in enhancing the performance of a concrete pump. It ensures a steady flow of concrete, reduces pressure fluctuations, and protects the pump from excessive wear and tear. This results in improved efficiency, reliability, and durability of the pump, ultimately leading to increased productivity and cost savings in concrete pumping operations.

- Q: How long do concrete pump pipes typically last?

- Concrete pump pipes typically last between 25,000 to 40,000 cubic meters of concrete pumped. However, the lifespan of these pipes can vary based on several factors such as the quality of the pipes, the type of concrete being pumped, the pumping pressure, and the maintenance practices followed. Regular inspections, cleaning, and proper storage can help extend the lifespan of concrete pump pipes. Ultimately, it is essential to monitor the wear and tear of the pipes and replace them when necessary to ensure efficient and safe concrete pumping operations.

- Q: How do I properly maintain and replace hydraulic pumps in concrete pump spare parts?

- Properly maintaining and replacing hydraulic pumps in concrete pump spare parts is crucial to ensure the smooth functioning and longevity of the equipment. Here are some steps to help you in this process: 1. Regular Inspections: Perform frequent visual inspections of the hydraulic pump to identify any signs of wear, leaks, or damage. Check for loose bolts, damaged seals, or excessive noise during operation. These inspections should be done before and after each use. 2. Follow Manufacturer's Guidelines: Refer to the manufacturer's guidelines and recommendations for maintenance and replacement of hydraulic pumps. They will provide specific instructions on the frequency of maintenance, lubrication, and replacement intervals. 3. Lubrication: Proper lubrication is essential for the smooth operation of hydraulic pumps. Check the oil levels regularly and top up if necessary. Use the recommended oil or hydraulic fluid as specified by the manufacturer. Follow the guidelines for the frequency of oil changes. 4. Regular Cleaning: Keep the hydraulic pump and its components clean from debris, dust, and dirt. Use a clean cloth or compressed air to remove any contaminants that may have accumulated. This will help prevent damage and reduce the risk of clogs or blockages. 5. Replace Worn Parts: Over time, certain components of the hydraulic pump may wear out and require replacement. Keep a stock of spare parts, including seals, gaskets, and filters, to be able to promptly replace any worn or damaged components. 6. Seek Professional Assistance: If you are unsure about any aspect of maintaining or replacing hydraulic pumps, it is always advisable to seek the assistance of a professional technician or the manufacturer. They have the expertise and knowledge to guide you through the process and ensure the best possible maintenance and replacement practices. Remember, regular maintenance and timely replacement of hydraulic pumps in concrete pump spare parts will not only extend the lifespan of the equipment but also ensure safe and efficient operation on construction sites.

- Q: What is the first generation pumping technology of concrete pump?

- Electronically controlled reversing technology, PLC control solenoid valve reversing to achieve the pump, S pipe distribution of alternating direction

- Q: What do these types of concrete pumps mean?

- 160 is the engine (or motor) rated power 160KW, and should also have 1-3 letters, RSU, said the diesel engine, S pipe ground pump, no R that is the motor pump, and some is only Z, that is the gate pump.

- Q: Can concrete pump spare parts be tested for performance and quality before installation?

- It is imperative to test concrete pump spare parts for performance and quality before installation. This ensures that they conform to necessary standards and specifications, and aids in detecting any flaws or concerns that might impact their performance or longevity. Testing can be carried out through diverse methods, including physical inspections, functional assessments, or deploying specialized equipment to gauge specific parameters. By conducting pre-installation tests on these spare parts, potential issues can be identified and rectified at an early stage, thereby guaranteeing peak performance and quality.

- Q: What is the function of a concrete pump water pump?

- The function of a concrete pump water pump is to supply water to the concrete pump system for various purposes. It is responsible for providing a continuous flow of water to the concrete pump, which helps in the mixing and pumping of concrete efficiently. The water pump ensures that the concrete mix remains at the desired consistency by adding water as needed during the pumping process. It helps to control the hydration process of the cement, preventing it from drying out and becoming unworkable. Additionally, the water pump also serves to clean the concrete pump system after use. It flushes out any excess concrete residue or debris that may have accumulated inside the pump, ensuring that it remains in good working condition. In summary, the function of a concrete pump water pump is to supply water for the mixing of concrete, maintain the desired consistency, and clean the concrete pump system.

- Q: What is the function of a concrete pump remote control antenna?

- The function of a concrete pump remote control antenna is to establish a wireless connection between the remote control device and the concrete pump. This allows the operator to remotely control the various functions of the concrete pump, such as starting and stopping the pump, adjusting the speed and flow of the concrete, and controlling the boom movements. The antenna receives signals from the remote control device and transmits them to the concrete pump, enabling the operator to control the pump from a safe distance. This helps improve efficiency, accuracy, and safety on construction sites by allowing the operator to have better visibility of the pump and its surroundings while still maintaining full control over its operations.

Send your message to us

DELIVERY CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM LENGTH:1545MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords