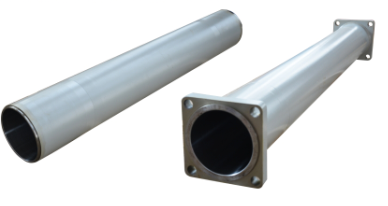

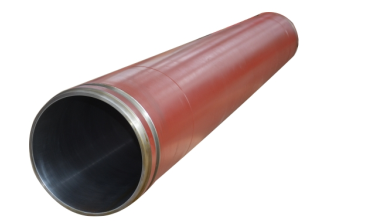

DELIVERY CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:2162MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: Can concrete pump spare parts be resold or traded in for new parts?

- Yes, concrete pump spare parts can be resold or traded in for new parts. Many suppliers and manufacturers offer buyback or exchange programs where customers can return their used parts and receive credit towards purchasing new ones. Reselling used parts is also common in the construction industry, as there is a demand for affordable alternatives to new parts. However, the resale value may vary depending on the condition and market demand for specific spare parts.

- Q: What are the specifications for concrete delivery pumps?

- The pressure of each safety valve of the hydraulic system of concrete pump shall comply with the requirements of the manual, and the user shall not adjust the change

- Q: What are the indications of a faulty control lever?

- There are multiple indications that may suggest a malfunctioning control lever. Firstly, if the control lever does not respond or is sluggish when attempting to engage or disengage a specific function, it could be indicative of an issue. This may include difficulties in shifting gears, adjusting speed, or operating various controls such as the throttle or clutch. Another sign of a faulty control lever is if it becomes loose or unstable. If you observe excessive play or movement in the lever, it could imply that the mechanism connecting the lever to the control system is worn out or damaged. This can compromise the accuracy and precision of the control lever, making it challenging to effectively operate the intended functions. Furthermore, any unusual noises or vibrations originating from the control lever can serve as an indication of a fault. This might be a consequence of loose or broken components within the control lever assembly, suggesting the need for inspection and repair. Lastly, if the control lever becomes stuck or jammed in a particular position, it clearly signifies a faulty lever. This can hinder proper control of the equipment or vehicle, posing safety risks. In any case, if there is suspicion of a faulty control lever, it is crucial to have it inspected and repaired by a qualified technician to ensure proper functioning and safe operation.

- Q: What is the purpose of a concrete pump agitator motor?

- The purpose of a concrete pump agitator motor is to mix and agitate the concrete mixture inside the pump, ensuring a consistent and homogenous blend. This helps to prevent the concrete from settling or segregating, ensuring a higher quality and more workable mixture for construction purposes.

- Q: What are the different types of concrete pump hopper agitator blades?

- The different types of concrete pump hopper agitator blades include spiral blades, flat blades, and paddle blades.

- Q: How often should hopper grate pin retainers be inspected or replaced in a concrete pump?

- To ensure proper functioning and prevent potential issues, it is important to regularly inspect hopper grate pin retainers in a concrete pump. Ideally, these inspections should be conducted on a monthly basis. However, the frequency of inspections may vary depending on usage conditions and manufacturer recommendations. During these inspections, it is essential to carefully examine the hopper grate pin retainers for any signs of wear, damage, or corrosion. If any of these issues are detected, immediate replacement is necessary to maintain the concrete pump's efficiency and safety. Furthermore, it is crucial to follow the manufacturer's guidelines regarding the lifespan of the hopper grate pin retainers. Some manufacturers may advise replacing them after a certain number of operating hours, while others may suggest replacement based on the condition observed during inspections. Regular inspections and timely replacement of hopper grate pin retainers play a crucial role in preventing malfunctions or accidents during concrete pumping operations. It is highly recommended to consult the concrete pump's manual or contact the manufacturer for specific guidelines on inspection and replacement intervals for hopper grate pin retainers.

- Q: How often should hopper pins be inspected or replaced in a concrete pump?

- To guarantee the safe and efficient operation of concrete pump equipment, it is imperative to regularly inspect and replace hopper pins. The frequency of these inspections and replacements depends on various factors, including the concrete pump's usage and the condition of the hopper pins. As a general rule, it is advised to inspect hopper pins every three to six months or after every 400 to 600 hours of operation. However, it is crucial to note that this timeframe can differ depending on the intensity and volume of concrete pumping activities. During the inspection, it is necessary to carefully examine the hopper pins for any indications of wear, damage, or deformation. If any pins display significant signs of wear, such as cracks, elongation, or excessive corrosion, they should be promptly replaced to prevent potential accidents or equipment failure. Maintaining the structural integrity of the concrete pump and ensuring the safety of operators and the surrounding environment rely heavily on regular inspection and replacement of hopper pins. It is advisable to consult the manufacturer's guidelines or seek professional advice to determine the specific schedule for inspection and replacement, considering the make and model of the concrete pump.

- Q: What is the purpose of a concrete pump cleaning ball?

- To effectively cleanse and eliminate any lingering concrete or debris inside a concrete pump system, a concrete pump cleaning ball serves its purpose. These cleaning balls are specifically designed for insertion into the pumping system and subsequent propulsion through the pipes using water pressure or compressed air. As they progress through the system, the cleaning balls effectively scrape away any solidified concrete or accumulation, guaranteeing unobstructed flow and optimal performance of the pump and pipes. This routine cleaning process not only prevents blockages and upholds pump efficiency but also prolongs the equipment's lifespan. Furthermore, the utilization of cleaning balls ensures that the subsequent batch of pumped concrete remains uncontaminated by any residual debris, resulting in a superior final product.

- Q: How can I determine if the concrete pump cylinder needs replacement?

- To determine if the concrete pump cylinder needs replacement, you can perform a few inspections and tests. 1. Visual inspection: Look for any visible signs of wear and tear on the cylinder, such as cracks, dents, or corrosion. Additionally, check for any leaks or excessive hydraulic fluid around the cylinder. 2. Performance evaluation: Pay attention to the pump's performance during operation. If you notice a decrease in pumping efficiency, irregular flow, or decreased pressure, it could indicate a problem with the cylinder. 3. Pressure testing: Conduct a pressure test to determine if the cylinder can handle the required pressure. This can be done by isolating the cylinder and pressurizing it to a level higher than what it typically experiences during operation. If the cylinder fails to maintain pressure or shows signs of leakage, it may be time for a replacement. 4. Cylinder stroke measurement: Measure the stroke length of the cylinder during operation. Uneven stroke lengths can indicate internal damage to the cylinder and may require replacement. 5. Consultation with experts: If you are unsure about the condition of the cylinder, it is advisable to consult with professionals or experts in the field. They can provide you with a more accurate assessment and recommend the appropriate course of action, which may include cylinder replacement. Keep in mind that regular maintenance and inspections are crucial for the longevity and efficient operation of the concrete pump. It is always better to address potential issues early on to avoid further damage or accidents.

- Q: How does the concrete pump work?

- The construction of automobile chassis, internal combustion engine, air compressor, water pump, hydraulic device, etc., which constitute the concrete pump truck, shall be operated in accordance with the safety instructions of the horizontal transport machinery, power plant and hydraulic machinery respectively

Send your message to us

DELIVERY CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:2162MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords