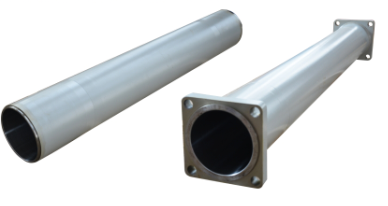

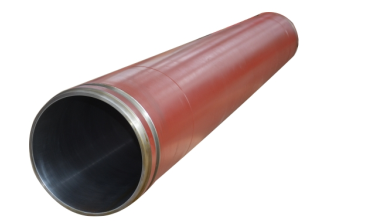

DELIVERY CYLINDER(SANY ) I.D.:DN200 CR. RED THICKNESS :0.25MM-0.3MM LENGTH:2162MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications DN200*2162

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: How do I properly maintain and replace hydraulic hoses in concrete pump spare parts?

- To ensure the smooth functioning and longevity of your equipment, it is crucial to properly maintain and replace hydraulic hoses in concrete pump spare parts. Here are some effective steps you can take: 1. Conduct regular visual inspections to identify any signs of wear, damage, or leaks. Look for bulges, cracks, abrasions, or fraying. Pay attention to fittings, connections, and bends in the hose. 2. Implement a preventive maintenance schedule to reduce the chances of unexpected hose failure. Clean the hoses regularly to remove dirt, debris, and concrete residues that may cause abrasion or clogging. Use a mild detergent and water, and ensure thorough drying. 3. Store hydraulic hoses in a clean, dry, and temperature-controlled environment when not in use. Protect them from direct sunlight, extreme temperatures, and chemicals to avoid degradation. 4. Handle hydraulic hoses with care to prevent damage. Avoid dragging them on rough surfaces or sharp edges that can cause cuts or abrasions. Minimize excessive kinking or twisting, as it weakens the internal structure. 5. Replace hydraulic hoses promptly upon noticing signs of wear, damage, or leaks. Do not wait for hose failure, as it can lead to costly downtime and safety hazards. Follow the manufacturer's recommendations for replacement intervals. 6. Use high-quality replacement hoses that are compatible with your concrete pump. Choose hoses that meet industry standards and specifications for durability in concrete pumping conditions. 7. Properly install replacement hoses, ensuring correct routing and secure connections to fittings. Use appropriate tools and techniques to tighten fittings, avoiding over-tightening that can damage the hose or fittings. 8. Provide regular training to your staff on proper maintenance, inspection, and replacement procedures for hydraulic hoses. This will enhance their knowledge and skills, reducing the risks of improper handling or installation. By following these steps, you can effectively maintain and replace hydraulic hoses in concrete pump spare parts, ensuring the safety and efficiency of your equipment. Always refer to the manufacturer's guidelines and seek professional assistance when needed.

- Q: Are there any specific guidelines for the installation of pipe or hose assemblies in concrete pump spare parts?

- Concrete pump spare parts have specific guidelines for the installation of pipe or hose assemblies, which are crucial for the pump system's proper and safe functioning. To ensure this, here are some key guidelines to consider: 1. Size and Compatibility: The pipe or hose assemblies must be appropriate in size and compatible with the concrete pump system. They should meet the pump's specifications and be designed for the intended application. 2. Correct Alignment: It is essential to install the pipe or hose assemblies straight, without any kinks or bends that may restrict the flow of concrete or cause blockages, thus ensuring efficient operation. 3. Secure Connections: To prevent leaks or disconnections during operation, all connections, including fittings and couplings, should be securely tightened. It is advisable to use proper tools and techniques to ensure reliable and tight connections. 4. Support and Protection: Proper support and protection of pipe or hose assemblies are necessary to prevent damage or wear. They should be securely fastened to minimize excessive movement or vibration during pumping operations. 5. Clearances and Accessibility: Maintaining sufficient clearances between the pipe or hose assemblies and surrounding structures or equipment allows for easy inspection, maintenance, and replacement if necessary. 6. Proper Sealing: Suitable sealing materials should be used to properly seal all joints and connections. This is crucial for maintaining the pumping system's integrity and preventing any environmental or safety hazards caused by leakage. 7. Regular Inspection and Maintenance: Regularly inspecting the pipe or hose assemblies for signs of wear, damage, or degradation is important. Promptly addressing any issues ensures the continued safe operation of the concrete pump system. By following these guidelines, the proper installation of pipe or hose assemblies in concrete pump spare parts can be ensured, promoting safe and efficient concrete pumping operations. It is also advisable to consult the manufacturer's recommendations and refer to any specific guidelines provided with the spare parts.

- Q: Can a concrete pump wear plate be repaired or does it need to be replaced entirely?

- In certain situations, a concrete pump wear plate may require repair or complete replacement. The determination of whether to repair or replace the wear plate depends on the extent of the damage and the overall condition of the plate. In the case of minor damages such as small cracks, dents, or worn out areas, suitable techniques can often be employed for repair. For instance, small cracks can be welded or filled with an appropriate epoxy or filler material. Similarly, dents or worn out areas can be filled and smoothed to restore the plate's functionality. However, if the wear plate has sustained significant damage, such as extensive cracks, severe corrosion, or large holes, it may be more advisable to replace the plate entirely. This is due to the potential compromise in the structural integrity and effectiveness of the wear plate if extensive damage is repaired. Optimal performance and safety of the concrete pump can be ensured by replacing the wear plate in these cases. Careful assessment of the wear plate's condition is crucial before deciding to repair or replace it. Seeking guidance from experts or professionals knowledgeable in concrete pump maintenance can provide valuable insights in making the appropriate decision. Additionally, regular maintenance and inspection of the wear plate can help detect potential issues early on, enabling timely repairs or replacements to prevent further damage and ensure the efficient operation of the concrete pump.

- Q: What are the types, classifications and specifications of concrete pump?

- According to the maximum hourly transport rate, there are 20-100m3 range, and most of the concrete pump can achieve two variable displacement or stepless variable

- Q: Are there any specific tools or equipment required for the installation of concrete pump spare parts?

- Yes, there are specific tools and equipment required for the installation of concrete pump spare parts. Some common tools include wrenches, socket sets, screwdrivers, hammers, and pliers. Additionally, specialized equipment like cranes, lifters, and hoists may be needed for lifting and positioning heavy components. It is important to use the appropriate tools and equipment to ensure proper installation and safety.

- Q: How do I properly maintain and replace hydraulic valves in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic valves in concrete pump spare parts is essential to ensure the smooth operation and longevity of the equipment. Here are some steps to follow: 1. Regular Inspection: Regularly inspect the hydraulic valves for any signs of wear, damage, or leakage. Look for cracks, corrosion, or any other visible defects. It is important to catch any issues early on to prevent further damage. 2. Cleanliness: Keep the hydraulic valves clean to prevent dirt, debris, or contaminants from entering the system. Use a suitable cleaning agent and a lint-free cloth to wipe the valves and remove any buildup. 3. Lubrication: Proper lubrication is crucial for the smooth operation of hydraulic valves. Refer to the manufacturer's guidelines to determine the appropriate lubricant and the recommended schedule for lubrication. Apply the lubricant as per the instructions provided. 4. Replacement: If a hydraulic valve is damaged or worn out beyond repair, it is important to replace it promptly. Identify the correct replacement valve by referring to the equipment's manual or consulting with the manufacturer. Ensure that the replacement valve matches the specifications required for your concrete pump. 5. Professional Assistance: While some maintenance tasks can be done by operators, it is advisable to seek professional assistance for complex maintenance and replacement procedures. Professional technicians have the expertise and knowledge to handle hydraulic valves safely and effectively. 6. Safety Precautions: Always adhere to proper safety protocols when working with hydraulic valves. Remove any sources of pressure and fully depressurize the system before attempting any maintenance or replacement. Wear appropriate personal protective equipment, such as gloves and safety goggles, to protect yourself from potential hazards. Overall, regular maintenance, timely replacement, and adherence to safety guidelines are essential for properly maintaining and replacing hydraulic valves in concrete pump spare parts. Following these steps will help ensure the reliable and efficient operation of your equipment.

- Q: How often should hopper agitator shaft bearings be inspected or replaced in a concrete pump?

- The hopper agitator shaft bearings in a concrete pump should be inspected regularly, at least once every six months, to ensure proper functioning. However, the exact frequency of replacement would depend on the manufacturer's recommendations, the intensity of usage, and the condition of the bearings. It is crucial to monitor the bearings for any signs of wear, damage, or excessive vibration, as this can lead to equipment failure and potential safety hazards.

- Q: What are some common issues with concrete pump pipes and how can they be prevented?

- Some common issues with concrete pump pipes include clogging, wear and tear, and leakage. These issues can be prevented by regularly cleaning the pipes to avoid clogging, using high-quality pipes that are resistant to wear and tear, and ensuring proper installation and maintenance to prevent leakage. Additionally, using the correct concrete mix and adjusting the pump pressure appropriately can also help prevent these issues.

- Q: How long do concrete pump hoses typically last?

- Concrete pump hoses typically last between 3 to 5 years, depending on factors such as usage frequency, maintenance, and the type of material being pumped.

- Q: How often should concrete pump remote control batteries be replaced?

- The replacement of concrete pump remote control batteries relies on several factors, including frequency of usage, battery quality, and environmental conditions. However, as a general rule, it is advisable to change the batteries every 6 to 12 months. This guarantees optimal functioning of the remote control and prevents unforeseen battery failures during crucial operations. Additionally, it is crucial to periodically assess battery performance and perform maintenance checks to ensure proper functionality.

Send your message to us

DELIVERY CYLINDER(SANY ) I.D.:DN200 CR. RED THICKNESS :0.25MM-0.3MM LENGTH:2162MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords