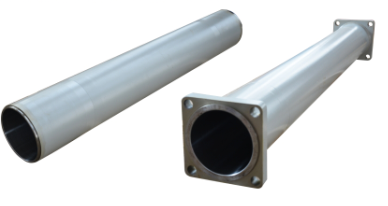

DELIVERY CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1946MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

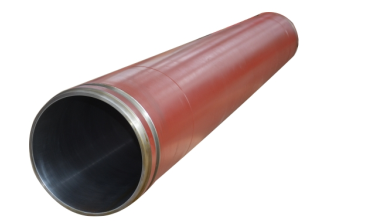

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: Are there any maintenance tips to extend the lifespan of concrete pump spare parts?

- Yes, there are several maintenance tips that can help extend the lifespan of concrete pump spare parts. 1. Regular Cleaning: It is important to regularly clean the spare parts to remove any dirt, debris, or concrete buildup. This can be done using a brush, water, and mild detergent. Cleaning helps prevent corrosion and ensures smooth operation. 2. Lubrication: Proper lubrication of moving parts is crucial to reduce friction and wear. It is important to follow the manufacturer's recommendations for lubrication intervals and use high-quality lubricants. Regularly inspect the lubrication points and replace any worn-out or damaged lubrication components. 3. Inspections and Maintenance: Regular inspections of all spare parts are necessary to identify any signs of wear, damage, or misalignment. Any issues should be repaired or replaced promptly. Additionally, following the maintenance schedule provided by the manufacturer is essential to address any potential problems before they escalate. 4. Proper Storage: When not in use, spare parts should be stored in a clean and dry environment to prevent rust and corrosion. They should be protected from extreme temperatures, moisture, and direct sunlight. Additionally, spare parts should be stored in a way that prevents any damage or deformation. 5. Correct Usage: It is crucial to operate the concrete pump in accordance with the manufacturer's guidelines. Overloading, excessive pressure, or improper operation can lead to premature wear and damage to the spare parts. Proper training should be provided to the operators to ensure they understand the correct usage techniques. 6. Regular Maintenance of the Concrete Pump: The overall condition of the concrete pump can have an impact on the lifespan of the spare parts. Regular maintenance of the pump, including cleaning, lubrication, and inspections, can help identify and address any potential issues that may affect the spare parts. By following these maintenance tips, the lifespan of concrete pump spare parts can be extended, reducing the need for frequent replacements and saving costs in the long run.

- Q: How can I minimize downtime during the replacement of concrete pump spare parts?

- Careful planning and efficient execution are essential for minimizing downtime when replacing concrete pump spare parts. Here are several strategies that can assist in achieving this goal: 1. Proactive maintenance: Establish a regular maintenance schedule to identify and replace worn-out parts before they malfunction. Regularly inspecting the concrete pump and its components can prevent unexpected breakdowns and reduce downtime. 2. Maintain spare parts inventory: Keep a stock of commonly needed spare parts, such as seals, filters, and hoses. This will significantly reduce the time spent on sourcing and ordering parts when a breakdown occurs. 3. Collaborate with dependable suppliers: Build relationships with reliable suppliers who can quickly provide high-quality spare parts. This ensures prompt access to the necessary components, minimizing delivery waiting time. 4. Train your team: Provide training to your maintenance and operational staff on efficiently identifying, troubleshooting, and replacing concrete pump spare parts. Equipping your team with the necessary skills enables them to promptly address issues, reducing overall downtime. 5. Schedule maintenance during low-demand periods: Plan maintenance and spare part replacement during periods of reduced demand or downtime. This could include weekends, holidays, or slower construction phases. Strategically scheduling the work ensures minimal impact on ongoing projects. 6. Optimize workflow: Identify areas causing delays or bottlenecks in your maintenance process. Seek opportunities to improve efficiency, such as optimizing the arrangement of spare parts, tools, and equipment, or implementing standardized repair and replacement procedures. 7. Utilize technology: Leverage technology to monitor the performance and condition of your concrete pump. Implementing a condition monitoring system can detect early signs of potential failures, allowing for proactive maintenance and part replacement. By implementing these strategies, you can minimize downtime during concrete pump spare part replacements, ensuring uninterrupted operations and maximizing productivity.

- Q: How often should wear rings be replaced in a concrete pump?

- Wear rings in a concrete pump should be replaced regularly, typically every 2,000 to 3,000 hours of operation. However, the frequency may vary depending on factors such as pump usage, maintenance practices, and the quality of materials being pumped. Regular inspection and monitoring of wear ring condition are essential to determine the appropriate replacement interval.

- Q: How often should control system sensors be calibrated or replaced?

- The calibration or replacement frequency of control system sensors varies depending on several factors, including the type of sensor, its application, environmental conditions, and the manufacturer's recommendations. Typically, it is advisable to calibrate control system sensors at least once a year. Nevertheless, certain sensors may necessitate more frequent calibration due to their sensitivity or importance in the system. For instance, sensors used in safety-critical applications or those exposed to harsh environmental conditions may require calibration every six months or even quarterly. Furthermore, it is vital to regularly monitor the performance of control system sensors to ensure accurate readings and dependable operation. This can be accomplished through routine maintenance and periodic checks. If any indications of sensor drift, inconsistency, or failure are observed during these checks, immediate calibration or replacement may be required. Additionally, the manufacturer's recommendations play a significant role in determining the intervals at which calibration or replacement should occur. Each sensor comes with its own specifications and guidelines provided by the manufacturer. It is crucial to adhere to these recommendations to maintain optimal performance and prolong the lifespan of the sensor. In conclusion, the calibration or replacement frequency of control system sensors should be determined by considering a combination of factors, including industry standards, application requirements, environmental conditions, and manufacturer's guidelines. Regular monitoring, routine maintenance, and adherence to these factors will ensure that control system sensors operate accurately and reliably.

- Q: How often should hopper grate springs be inspected or replaced in a concrete pump?

- Hopper grate springs in a concrete pump should be inspected regularly to ensure optimal performance and prevent any potential issues. The frequency of inspection or replacement depends on several factors such as the pump's usage, operating conditions, and the manufacturer's recommendations. However, a general guideline is to inspect the hopper grate springs at least once every six months or after every 500 hours of operation, whichever comes first. During the inspection, it is important to thoroughly examine the springs for any signs of wear, damage, or deformation. Look for cracks, excessive rust, or loss of tension in the springs. If any of these issues are detected, immediate replacement is necessary to maintain the proper functioning of the hopper grate system. Regular inspection and timely replacement of hopper grate springs are crucial to prevent clogging or blockage in the hopper, which could lead to pump malfunctions or downtime. It is advisable to consult the concrete pump manufacturer's guidelines or seek assistance from a professional technician to determine the specific inspection and replacement intervals based on the pump's make and model.

- Q: Are there any online resources or manuals available for concrete pump spare parts?

- Yes, there are several online resources and manuals available for concrete pump spare parts. Many manufacturers and suppliers of concrete pump spare parts have their own websites where they provide detailed information about their products, including manuals, catalogs, and technical specifications. These websites often have dedicated sections or pages specifically for spare parts, where you can find information about different types of spare parts, their compatibility with various pump models, and how to order them. In addition to manufacturer websites, there are also numerous online marketplaces and directories that specialize in construction equipment and spare parts. These platforms allow you to search for specific concrete pump spare parts and compare prices and specifications from different suppliers. Some of these platforms may also provide additional resources such as user reviews, ratings, and guides on how to select the right spare parts for your specific pump model. Furthermore, there are online forums and communities where professionals in the construction industry discuss and share information about concrete pumps and their spare parts. These forums can be a valuable resource for finding recommendations, troubleshooting common issues, and connecting with experts who can provide guidance on sourcing and maintaining spare parts for concrete pumps. Overall, whether you are a concrete pump operator, maintenance technician, or someone looking to purchase spare parts for a concrete pump, there are plenty of online resources available to help you find the information and manuals you need.

- Q: Can I get spare parts for both single-cylinder and multi-cylinder concrete pumps?

- Spare parts for both single-cylinder and multi-cylinder concrete pumps are readily available. Various manufacturers and suppliers offer a wide range of spare parts for different concrete pump types, including single-cylinder and multi-cylinder models. These spare parts comprise hydraulic cylinders, pistons, seals, valves, hoses, and other crucial components that may require replacement due to wear and tear or damage. To ensure compatibility and availability, it is vital to contact the concrete pump's specific manufacturer or supplier and inquire about the spare parts suitable for your particular model.

- Q: Are there any regulatory requirements for the quality and standards of concrete pump spare parts?

- Concrete pump spare parts are subject to regulatory requirements that govern their quality and standards. These requirements are in place to guarantee safety, performance, and durability. These regulations are established by entities such as governmental agencies or industry associations, with the aim of safeguarding consumers and ensuring the proper functioning of concrete pumps. Several common regulatory requirements apply to concrete pump spare parts: 1. Certification: Authorized organizations may certify spare parts or subject them to specific testing processes to verify compliance with quality and performance standards. This certification helps ensure the safety and reliability of the spare parts. 2. Material Standards: Specific material standards may be imposed on spare parts. For example, the materials used in their construction must meet requirements for strength, corrosion resistance, or temperature resistance. 3. Design and Manufacturing Standards: The design and manufacturing processes of spare parts must adhere to certain standards. These standards cover dimensions, tolerances, manufacturing techniques, and quality control procedures in order to ensure consistent and reliable performance. 4. Performance and Compatibility Standards: Spare parts should be designed and manufactured to perform within defined parameters and be compatible with the concrete pump system they are intended for. This guarantees proper and safe functioning of the spare parts when installed in the pump. 5. Documentation and Labeling: Regulatory requirements often mandate that spare parts be accompanied by proper documentation, including user manuals, installation instructions, and maintenance guidelines. Additionally, labeling requirements may exist to clearly identify the spare parts and their specifications. Manufacturers, suppliers, and users of concrete pump spare parts must be aware of and comply with these regulatory requirements to ensure the safety and effectiveness of the concrete pump system.

- Q: What is the role of a concrete pump hopper grate pin retainer?

- The role of a concrete pump hopper grate pin retainer is to secure the grate pins in place, preventing them from dislodging or falling out during the pumping process. This helps to maintain the stability and integrity of the hopper grate, ensuring efficient and safe operation of the concrete pump.

- Q: Can concrete pump spare parts be imported from other countries?

- Yes, concrete pump spare parts can be imported from other countries. Many manufacturers and suppliers of concrete pump spare parts have a global presence and offer international shipping options. Importing concrete pump spare parts from other countries can provide access to a wider range of products, competitive pricing, and high-quality components. However, it is important to consider factors such as import regulations, customs duties, and shipping costs when importing concrete pump spare parts from other countries.

Send your message to us

DELIVERY CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1946MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords