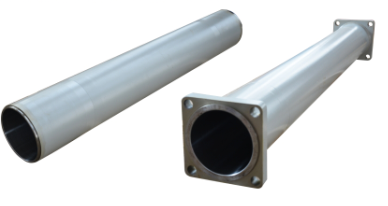

DELIVERY CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM LENGTH:1605MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

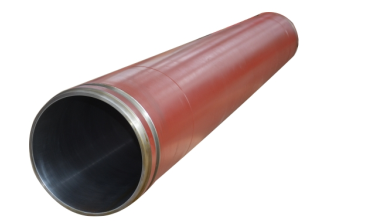

Concrete Pump Delivery Cylinder DN180*1605

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: Are there any specific guidelines for the installation of pistons or cylinders in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of pistons or cylinders in concrete pump spare parts. These guidelines are important to ensure proper functioning and longevity of the equipment. 1. Clean and inspect: Before installing pistons or cylinders, it is crucial to thoroughly clean and inspect them for any damage or defects. Any debris or contaminants should be removed to prevent potential issues during operation. 2. Lubrication: Apply a suitable lubricant to the piston or cylinder to reduce friction and ensure smooth movement. This will also help in preventing wear and tear, enhancing the lifespan of the parts. 3. Alignment: Proper alignment of the piston or cylinder is essential. Ensure that the piston is aligned correctly with the cylinder bore to avoid any binding or excessive wear. This can be achieved by following the manufacturer's instructions or consulting a professional if necessary. 4. Torque specifications: It is important to tighten the bolts or fasteners according to the manufacturer's recommended torque specifications. Over-tightening or under-tightening can lead to problems such as leaks or mechanical failure. 5. Sealing: Use appropriate sealing materials, such as gaskets or O-rings, to ensure a proper seal between the piston and cylinder. This will prevent fluid leakage and maintain the efficiency of the equipment. 6. Testing: After installation, it is recommended to test the pistons or cylinders to ensure they are functioning correctly. This can involve performing a trial run or conducting pressure tests to check for any leaks or abnormalities. Following these guidelines will help ensure the proper installation of pistons or cylinders in concrete pump spare parts, leading to reliable and efficient operation of the equipment. It is always advisable to refer to the manufacturer's instructions or seek professional assistance if there are any doubts or concerns during the installation process.

- Q: Can concrete pump spare parts be customized for specific pump models?

- Yes, concrete pump spare parts can be customized for specific pump models. Concrete pumps come in various sizes and designs, and each model may have unique specifications and requirements for its spare parts. To ensure compatibility and optimal performance, it is important to customize the spare parts according to the specific pump model. This customization can include dimensions, materials, and other technical specifications that are tailored to fit the particular pump model. By customizing the spare parts, it ensures a perfect fit and enhances the efficiency and longevity of the concrete pump. Additionally, customization allows for potential improvements or modifications to the original design, resulting in enhanced performance and durability of the pump. Therefore, it is crucial to work with reputable manufacturers or suppliers who can provide customized concrete pump spare parts for specific pump models.

- Q: Can I get spare parts for both concrete pumps with and without pressure washers?

- Yes, spare parts are available for both concrete pumps with and without pressure washers.

- Q: How long do concrete pump pipes typically last?

- Concrete pump pipes typically last between 25,000 to 40,000 cubic meters of pumped concrete, depending on various factors such as pump usage, maintenance, and the type of concrete being pumped.

- Q: What are the different types of concrete pump control system sensors?

- There are several different types of sensors used in concrete pump control systems to ensure smooth and efficient operation. These sensors are designed to monitor various aspects of the pump's performance and provide real-time feedback to the control system. Some of the common types of sensors used in concrete pump control systems include: 1. Pressure Sensors: These sensors are used to measure the pressure of the concrete being pumped. They are typically installed in the discharge line and help to ensure that the pump is operating within the desired pressure range. Pressure sensors are crucial in preventing over-pressurization and potential damage to the pump or pipeline. 2. Flow Sensors: Flow sensors are employed to measure the flow rate of the concrete. By monitoring the volume of concrete passing through the system per unit of time, these sensors enable the control system to regulate the speed and output of the pump accordingly. Flow sensors help in maintaining a consistent and controlled flow of concrete during pumping operations. 3. Level Sensors: Level sensors are utilized to monitor the level of concrete in the hopper or storage tank. These sensors provide information to the control system about the concrete volume, ensuring that the pump is not running dry or becoming overloaded. By maintaining the appropriate level of concrete in the hopper, level sensors help to prevent pump cavitation or blockages. 4. Proximity Sensors: Proximity sensors are used to detect the position of various moving parts in the pump system, such as the boom or outriggers. They provide feedback to the control system, ensuring that the pump operates safely and avoids any potential collisions or obstructions. Proximity sensors play a crucial role in preventing accidents and protecting both the equipment and personnel. 5. Temperature Sensors: Temperature sensors are employed to monitor the temperature of the concrete mix. These sensors help to ensure that the concrete remains within the desired temperature range during pumping, as extreme temperatures can affect the workability and curing process. By maintaining the optimal concrete temperature, temperature sensors contribute to the quality of the final product. Overall, these sensors work together to provide precise and reliable feedback to the control system, allowing for efficient and safe operation of the concrete pump. By continuously monitoring and adjusting various parameters, the sensors help to optimize pumping performance and enhance the overall productivity of concrete placement projects.

- Q: What are the fittings of concrete pump?

- Hydraulic oil, eye plates, cutting rings (when the equipment reaches 5000 or more sides can be prepared) and so on

- Q: What are the different types of concrete pump clamps?

- There are several different types of concrete pump clamps, including snap clamps, bolt clamps, wedge clamps, and quick release clamps. These clamps are used to secure pipes and hoses in place and ensure a tight and secure connection during concrete pumping operations.

- Q: Can I get spare parts for concrete pump boom arms and pipes?

- Concrete pump boom arms and pipes can definitely be replaced with spare parts. Many suppliers and manufacturers specialize in providing these spare parts for concrete pumps. These spare parts include boom arms, pipes, couplings, gaskets, seals, and other components necessary for proper concrete pump function. To find these spare parts, you can conduct an online search. Numerous websites and online stores offer a wide range of options. It is crucial to purchase spare parts from reputable suppliers to ensure their quality and compatibility with your specific concrete pump model. Moreover, local dealers and distributors also stock spare parts for concrete pumps. You can inquire with them or visit their stores to find the necessary spare parts for your boom arms and pipes. Efficient and safe operation of a concrete pump requires regular maintenance and replacement of worn-out or damaged parts. By investing in high-quality spare parts, you can extend the lifespan of your equipment and ensure optimal performance.

- Q: How often should hydraulic oil filters be replaced in a concrete pump?

- Hydraulic oil filters in a concrete pump should be replaced regularly according to the manufacturer's recommendations. Typically, it is recommended to replace hydraulic oil filters every 500 to 1,000 hours of operation or annually, whichever comes first. However, the specific replacement frequency may vary based on factors such as the operating conditions, environment, and the quality of hydraulic oil used. Regular maintenance and monitoring of the filter's condition can help determine the appropriate replacement interval to ensure efficient and reliable performance of the concrete pump.

- Q: What is the purpose of a concrete pump piston?

- The purpose of a concrete pump piston is to provide the necessary pressure to push the concrete mixture from the hopper into the delivery pipeline. The piston is responsible for generating the force required to propel the concrete through the system, effectively transporting it to its intended destination. This is achieved by the reciprocating motion of the piston, which creates suction on one side and pressure on the other, enabling the concrete to be pushed forward. Overall, the concrete pump piston plays a crucial role in facilitating the efficient and continuous movement of concrete, making it an essential component in construction projects that require the precise and timely placement of concrete.

Send your message to us

DELIVERY CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM LENGTH:1605MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords