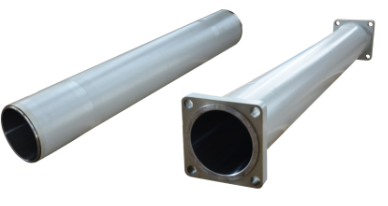

DELIVERY CYLINDER(PM ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: Are there any special tools required for replacing concrete pump spare parts?

- Yes, there are special tools required for replacing concrete pump spare parts. These tools may include wrenches, screwdrivers, hydraulic jacks, cranes or hoists, and specific equipment for removing and installing components such as seals, bearings, or pistons. Additionally, some specialized tasks may require the use of a welding machine or cutting tools. It is important to have the right tools to ensure a safe and efficient replacement process.

- Q: What are the indications of a faulty control lever?

- Some indications of a faulty control lever may include difficulty in shifting gears, a loose or wobbly lever, or the lever not returning to its original position after being released. Other signs could be grinding or crunching noises when engaging the lever, or if the lever feels sticky or unresponsive.

- Q: What are the signs of a malfunctioning lubrication system?

- Some signs of a malfunctioning lubrication system include increased friction and heat, unusual noises coming from the engine or components, excessive wear and tear on moving parts, and a decrease in overall performance and efficiency of the machinery or vehicle.

- Q: Are there any specific maintenance procedures for concrete pump spare parts?

- Yes, there are specific maintenance procedures for concrete pump spare parts. It is important to regularly inspect and clean the spare parts to remove any debris or blockages that may affect their performance. Additionally, lubrication should be applied to moving components to ensure smooth operation. Regular maintenance and timely replacement of worn-out or damaged parts is crucial to maximize the lifespan and efficiency of concrete pump spare parts.

- Q: What are some common issues with concrete pump hoses and how can they be prevented?

- Concrete pump hoses can encounter various problems such as blockages, leaks, and premature wear. To avoid these issues, it is essential to adhere to proper maintenance and usage practices. 1. Blockages: Blockages can occur when concrete or debris hardens inside the hoses. Thoroughly cleaning the hoses after each use is crucial to prevent blockages. Flushing the hoses with water or using a cleaning sponge ball effectively removes any residue or build-up. Additionally, using the correct size and length of hose for the job reduces the risk of blockages. 2. Leaks: Leaks may result from wear and tear, improper connections, or hose damage. Regularly inspecting the hoses is vital to detect any signs of leakage. Any leaks detected should be promptly repaired or replaced. Properly connecting and securing the hose fittings also helps prevent leaks. 3. Premature Wear: Over time, concrete pump hoses can wear out due to factors such as abrasion, bending, and exposure to harsh chemicals. Handling the hoses with care and avoiding dragging them on rough surfaces is important to prevent premature wear. Using protective sleeves or guards provides additional protection against abrasion. Regularly inspecting the hoses for signs of wear and replacing them when necessary is essential. 4. Storage Practices: Improper storage of concrete pump hoses can cause damage and reduce their lifespan. Storing the hoses in a clean and dry environment away from direct sunlight and extreme temperatures is recommended. Properly coiling the hoses and avoiding sharp bends or kinks helps maintain their integrity. 5. Pressure Management: Exceeding the recommended pressure limits can result in hose bursts or failures. Ensuring that the concrete pump operates within the specified pressure range is crucial. Regularly inspecting the pressure gauges and monitoring the pumping process aids in preventing over-pressurization. By adhering to these preventive measures, conducting regular inspections, and performing necessary maintenance, the common issues associated with concrete pump hoses can be minimized. This, in turn, leads to improved performance and increased longevity of the hoses.

- Q: Can concrete pump spare parts be inspected for dimensional accuracy before installation?

- Yes, concrete pump spare parts can be inspected for dimensional accuracy before installation. Before installing any spare parts, it is important to ensure that they meet the required specifications and dimensions to ensure proper functioning and compatibility with the concrete pump system. Inspection can be done using various methods such as visual inspection, measuring with precision instruments, and comparing the dimensions with the manufacturer's specifications. This process helps to identify any discrepancies or deviations in the dimensions of the spare parts, allowing for adjustments or replacement if necessary. Inspecting spare parts for dimensional accuracy before installation helps to ensure the smooth operation and longevity of the concrete pump system.

- Q: Are there any specific troubleshooting steps for identifying issues with concrete pump spare parts?

- Concrete pump spare parts can be identified for issues by following specific troubleshooting steps. These steps include conducting a thorough visual inspection of the spare parts to look for signs of wear, damage, or misalignment. Cracks, breaks, or any visible signs of damage should be checked for. The functionality of the spare parts can be tested by operating the concrete pump and paying attention to abnormal noises, vibrations, or irregular movements. A pressure test can be performed by connecting a pressure gauge to the pump and checking if it reaches the desired pressure levels. Any abnormal pressure fluctuations can indicate issues. A flow test can be conducted to evaluate the flow rate of the concrete through the pump and check for any blockages or irregular flow patterns. The spare parts should be inspected for leaks or fluid seepage, which can indicate faulty seals, gaskets, or fittings. Technical manuals provided by the manufacturer can be consulted for troubleshooting guidelines specific to the concrete pump spare parts. If unable to identify the issue, it is advisable to seek expert advice from a qualified technician or the manufacturer's technical support team. By following these troubleshooting steps, it becomes easier to promptly identify and address any issues with concrete pump spare parts.

- Q: Are there any specific safety precautions while replacing concrete pump spare parts?

- There exists a variety of safety precautions that must be followed when replacing concrete pump spare parts. 1. Personal Protective Equipment (PPE) is of utmost importance and should be worn to safeguard against potential hazards. This includes safety goggles, gloves, a helmet, and steel-toed boots. 2. It is essential to adhere to proper lockout/tagout procedures prior to replacing any spare parts. This entails disconnecting and securing the power source to prevent accidental startup of the pump. 3. Before commencing the replacement process, inspect all tools and equipment for any indications of damage or defects. It is crucial to refrain from using faulty equipment, as it can pose significant safety risks. 4. When handling heavy spare parts, it is imperative to employ appropriate lifting techniques to prevent strain or injury. Ensure that proper assistance and equipment, such as cranes or forklifts, are available if necessary. 5. Maintain a clean and well-organized work area to prevent trips, slips, and falls. Remove any obstacles or debris that may jeopardize safety during the replacement process. 6. Only trained and authorized personnel should be involved in the replacement of concrete pump spare parts. They must possess a thorough understanding of the equipment and procedures to minimize the likelihood of accidents. 7. Always consult the manufacturer's guidelines and instructions when replacing spare parts. This will ensure that the process is executed safely and accurately. 8. It is vital to have a plan in place for potential emergencies, including fires or injuries. Make certain that fire extinguishers and first aid kits are easily accessible, and that all workers are familiar with their locations and usage. By adhering to these safety precautions, the risk of accidents, injuries, and damage can be significantly reduced when replacing concrete pump spare parts.

- Q: How often should agitator shaft seals be replaced in a concrete pump?

- The frequency at which agitator shaft seals should be replaced in a concrete pump depends on several factors such as the type and quality of the seal, the operational conditions of the pump, and the maintenance practices followed by the user. However, as a general guideline, it is recommended to inspect and replace agitator shaft seals in a concrete pump every 500 to 1,000 operating hours or annually, whichever comes first. Regular inspection of the seals is crucial to identify any signs of wear, leakage, or damage. If any of these issues are detected, immediate replacement is necessary to prevent further damage to the pump and ensure optimal performance. Additionally, it is essential to follow the manufacturer's recommendations and guidelines regarding seal replacements, as they may provide specific instructions based on the pump model and seal type. Proper maintenance practices, including regular cleaning and lubrication of the seals, can also extend their lifespan and reduce the need for frequent replacements. It is important to keep in mind that failure to replace worn or damaged agitator shaft seals in a timely manner can lead to increased downtime, decreased efficiency, and potential damage to other components of the concrete pump. Hence, it is crucial to prioritize regular inspection and replacement of agitator shaft seals to ensure the smooth operation and longevity of the concrete pump.

- Q: How do I properly maintain and replace wear plates in concrete pump spare parts?

- Achieving optimal performance and durability for your equipment relies heavily on the proper maintenance and replacement of wear plates in concrete pump spare parts. To ensure that your wear plates are adequately maintained and replaced, the following steps can be taken: 1. Conduct regular inspections: It is crucial to regularly inspect the wear plates in your concrete pump spare parts in order to identify any signs of wear or damage. Look for visible indications such as cracks, excessive wear, or deterioration. 2. Thoroughly clean the area: Prior to replacing the wear plates, it is essential to thoroughly clean the surrounding area. Remove any debris, dirt, or hardened concrete that may be present. Utilize a pressure washer or wire brush to effectively clean the surface. 3. Measure the thickness of wear plates: Utilize a precision measuring tool to determine the thickness of the wear plates. Compare the current thickness with the manufacturer's recommended specifications to determine if replacement is necessary. If the wear plates are below the recommended thickness, replacement is required. 4. Remove the old wear plates: Carefully remove the old wear plates using the appropriate tools. Take note of their positions and any alignment marks to ensure proper installation of the new plates. 5. Prepare the new wear plates: Prior to installing the new wear plates, verify that they are the correct size and meet the required specifications for your concrete pump. Inspect the new plates for any defects or damage before proceeding. 6. Apply lubrication: Apply a thin layer of lubricant or anti-seize compound to the mating surface of the new wear plates. This will aid in preventing corrosion and facilitate future replacements. 7. Install the new wear plates: Position the new wear plates accurately, aligning them with any reference marks or indicators. Secure them tightly using suitable bolts or fasteners, taking care not to overtighten. 8. Test and check alignment: After installing the new wear plates, perform a test run of the concrete pump to ensure proper functionality. Check for any leaks, uncommon vibrations, or misalignments. If any issues are detected, address them promptly. 9. Establish a regular maintenance schedule: To prevent premature wear and damage to the wear plates, create a routine maintenance schedule. This may involve cleaning, lubricating, and inspecting the wear plates at specified intervals or after a certain number of operational hours. By adhering to these steps and adopting a proactive approach to wear plate maintenance and replacement, you can guarantee the seamless operation and extended lifespan of your concrete pump spare parts.

Send your message to us

DELIVERY CYLINDER(PM ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords