PUMPING CYLINDER(PM) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

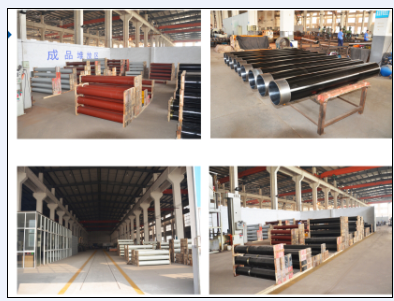

Product Description:

The Concrete Pump Delivery Cylinder DN230*1600normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder DN230*1600 is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder Cylinder DN230*1600can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pump Delivery Cylinder DN180*1545

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN230*1600Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN230*1600?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN180*1545?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders DN230*1600according to customers request?

A4: Yes, we can produce Cylinders DN230*1600according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world.

- Q: What is the name of the pump for concrete transportation?

- The concrete name of concrete pump is concrete pump truck. Concrete pump truck is a kind of machine which can transport concrete along pipeline continuously by pressure. It is composed of pump body and conveying pipe.

- Q: How long does it take to receive concrete pump spare parts after ordering?

- The delivery time for concrete pump spare parts can differ based on various factors. It is crucial to acknowledge that the availability of the specific parts you require and the location of the supplier can have a significant impact on the time it takes for them to arrive. Generally, if the spare parts are readily available and in stock, you can expect to receive them within a few days to a week. This assumes that the supplier has an efficient order processing system and prompt shipping arrangements. However, if the spare parts are not in stock, the duration to receive them may be longer. In such instances, the supplier might need to order the parts from a manufacturer or source them from a distributor. This could result in additional lead time for delivery, ranging from a few weeks to several months, depending on availability and the sourcing process. To obtain an estimate of the delivery time, it is advisable to consult with the supplier or manufacturer before placing your order. Additionally, factors like the supplier's location, transportation mode, and potential customs or logistics delays should be taken into consideration. If you require the spare parts urgently, some suppliers may offer expedited shipping options for an extra cost. This can be advantageous in expediting the delivery process. In conclusion, the time it takes to receive concrete pump spare parts after ordering can vary. However, by being proactive, maintaining communication with the supplier, and planning ahead, you can help ensure a smoother and quicker delivery process.

- Q: How can a faulty concrete pump cylinder affect the pumping process?

- The pumping process can be significantly impacted by a faulty cylinder in the concrete pump. The cylinder's role is crucial in the concrete pumping system as it generates the necessary pressure to push the concrete through the pipes and hoses. A decrease in pumping efficiency is one of the main issues caused by a faulty cylinder. If the cylinder is worn out or damaged, it may not generate sufficient pressure to effectively push the concrete. This can lead to a decrease in the pumping rate and overall productivity of the concrete pumping operation. Moreover, a faulty cylinder can cause irregular and inconsistent flow of concrete. This can result in blockages or clogs in the pipes, disrupting the pumping process. Removing these blockages can be time-consuming and costly, as it may require disassembling the pumping system to access and clear the blocked area. Additionally, leaks can occur in the pumping system due to a faulty cylinder. These leaks not only waste concrete but also reduce the overall pressure in the system, impacting the ability to pump the concrete to the desired location. Furthermore, leaks can create a messy worksite, posing safety risks for workers and potentially damaging surrounding structures. Furthermore, the risk of equipment failure is increased by a faulty cylinder. If the cylinder malfunctions or fails completely, it can cause the entire pumping system to shut down. This can result in significant downtime and delays in the concrete pouring process, leading to additional costs and potential penalties. In conclusion, a faulty concrete pump cylinder can have a significant impact on the pumping process by reducing efficiency, causing irregular flow, promoting leaks, and increasing the risk of equipment failure. To ensure smooth and efficient concrete pumping operations, it is essential to regularly maintain, inspect, and replace the cylinder in a timely manner.

- Q: How often should hopper agitator motors be inspected or replaced in a concrete pump?

- The frequency at which hopper agitator motors should be inspected or replaced in a concrete pump depends on various factors such as the usage intensity, operating conditions, and maintenance practices. However, as a general guideline, it is recommended to inspect hopper agitator motors regularly, at least once every three to six months. Regular inspections can help identify any signs of wear and tear, damage, or malfunctioning in the motor. This can include issues such as abnormal noise, excessive vibrations, overheating, or reduced performance. Additionally, it is important to check for any loose or worn out components, such as belts, pulleys, or bearings, which could affect the motor's efficiency and lifespan. If any significant issues or malfunctions are detected during the inspection, it may be necessary to replace the hopper agitator motor. The decision to replace the motor should be based on the severity of the problem, the age of the motor, and the cost-effectiveness of repairs compared to a replacement. Besides regular inspections, it is crucial to follow the manufacturer's recommendations for maintenance and lubrication of the hopper agitator motor. Proper maintenance practices can extend the lifespan of the motor and minimize the need for replacement. Ultimately, the specific frequency of inspections and replacement of hopper agitator motors in a concrete pump should be determined based on the specific circumstances and conditions in which the pump is operated, in consultation with the manufacturer's guidelines and recommendations.

- Q: How to calculate the power of concrete pump motor?

- Second, the amount of transport is the amount of export pressure is determined,

- Q: How do I maintain and clean concrete pump spare parts?

- Maintaining and cleaning concrete pump spare parts involves regular inspections, lubrication, and following proper cleaning procedures. Firstly, conduct routine checks to identify any signs of wear, damage, or loose connections. Lubricate the moving parts as recommended by the manufacturer to ensure smooth operation and prevent rust. When cleaning, use a mild detergent and water solution to remove any dirt, debris, or concrete residue. Avoid using harsh chemicals or abrasive tools that could damage the parts. It's crucial to follow the manufacturer's guidelines and consult the equipment manual for specific instructions on maintaining and cleaning concrete pump spare parts.

- Q: Can I get spare parts for both concrete pumps with and without water tanks?

- Indeed, spare parts are readily accessible for both concrete pumps equipped with water tanks and those without. A multitude of manufacturers and suppliers present an extensive array of spare parts for concrete pumps, encompassing diverse models with or without water tanks. These spare parts serve the purpose of regular maintenance, repairs, or replacements for a variety of components, including hoses, pipes, valves, cylinders, seals, and other essential elements. Prioritizing the acquisition of appropriate spare parts tailored to your specific concrete pump model is crucial to guarantee compatibility and achieve optimal performance.

- Q: What do these types of concrete pumps mean?

- 160 is the engine (or motor) rated power 160KW, and should also have 1-3 letters, RSU, said the diesel engine, S pipe ground pump, no R that is the motor pump, and some is only Z, that is the gate pump.

- Q: What are the advantages of using genuine spare parts for my concrete pump?

- Using genuine spare parts for your concrete pump comes with several advantages. First and foremost, genuine spare parts are specifically designed and manufactured by the original equipment manufacturer (OEM) for your concrete pump. This means that they are made to fit perfectly and function optimally with your specific model. Using genuine parts ensures compatibility and reduces the risk of compatibility issues or malfunctions that can arise from using aftermarket or counterfeit parts. Secondly, genuine spare parts are made from high-quality materials and undergo rigorous testing to meet strict quality standards. This ensures their durability, reliability, and performance, ultimately resulting in longer service life and reduced downtime for your concrete pump. Genuine parts are designed to withstand the demanding conditions and heavy loads that concrete pumps typically operate under. Moreover, using genuine spare parts helps maintain the warranty and integrity of your concrete pump. Many manufacturers offer warranties that cover the use of genuine parts. By using genuine parts, you can take advantage of the warranty benefits and avoid any potential issues that may arise from using non-genuine parts, which could void the warranty. Additionally, genuine spare parts often come with technical support and expertise from the manufacturer. OEMs have extensive knowledge and experience with their equipment, and their technical support team can provide guidance, advice, and troubleshooting assistance in case any issues arise. This can be extremely beneficial in minimizing downtime and maximizing the efficiency of your concrete pump. Lastly, using genuine spare parts ensures the safety of your equipment and operators. Genuine parts are manufactured to meet strict safety regulations and standards, reducing the risk of accidents or failures that can result from using substandard or counterfeit parts. The safety and well-being of your team should always be a top priority, and using genuine parts helps ensure their protection. In conclusion, the advantages of using genuine spare parts for your concrete pump include compatibility, quality, durability, warranty coverage, technical support, and safety. Investing in genuine parts not only enhances the performance and longevity of your equipment but also provides peace of mind for both you and your team.

- Q: How do concrete pump spare parts contribute to the overall performance of the pump?

- Enhancing the overall performance of the pump, concrete pump spare parts play a crucial role. These spare parts are specifically designed to endure the harsh and demanding conditions of pumping concrete, guaranteeing the efficiency and longevity of the pump. An important factor in the pump's overall performance is the ability of concrete pump spare parts to enhance pumping capacity and efficiency. These spare parts, including pump cylinders, pistons, and valves, are designed to ensure a consistent and smooth flow of concrete without any interruptions. By maintaining a steady flow, these spare parts maximize the pump's capacity, enabling it to handle larger volumes of concrete in less time. Furthermore, concrete pump spare parts contribute to the pump's performance by improving its durability and reliability. These spare parts are made from high-quality materials like hardened steel and wear-resistant alloys, specifically chosen to withstand the abrasive nature of concrete. This ensures that the pump can operate continuously without experiencing premature wear or failure. Concrete pump spare parts also ensure the safety of the pump operators and the environment. For instance, wear plates and cutting rings prevent concrete leakage, reducing the risk of accidents and environmental contamination. Similarly, seals and gaskets provide a secure and tight connection between different components, preventing leaks or malfunctions. Moreover, concrete pump spare parts reduce downtime and maintenance costs. As these spare parts undergo wear and tear during operation, they are designed to be easily replaceable. This allows for quick and efficient repair or replacement of damaged parts, minimizing the pump's downtime. Additionally, using genuine and high-quality spare parts reduces the need for frequent repairs and maintenance, resulting in lower overall maintenance costs. In conclusion, concrete pump spare parts are vital components that significantly contribute to the pump's overall performance. They enhance its pumping capacity, durability, and reliability, ensuring a smooth and efficient operation. Furthermore, these spare parts promote safety, reduce downtime, and minimize maintenance costs, making them indispensable for the optimal performance of concrete pumps.

Send your message to us

PUMPING CYLINDER(PM) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords