Hot Forged 1045 Carbon Round Steel Bar with black/turned/grinded

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot forged 1045 carbon round steel bar with black/turned/grinded

Product information

1. Produce Standard: GB, AISI, ASTM, SAE, EN, BS, DIN, JIS

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment: Normalized / Annealed / Quenched+Tempered

4. Quality assurance: All order we can received third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product detail

| Material | AISI 1045, S45C, C45, 1.0503, 45 | Round bar | Dia(mm) | Max 700 |

| Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12000 | |

| Heat treatment | Normalized / Annealed / Quenched / tempered | Plate bar | Thickness(mm) | Max 200 |

| Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | Max 3000 | |

| Test |

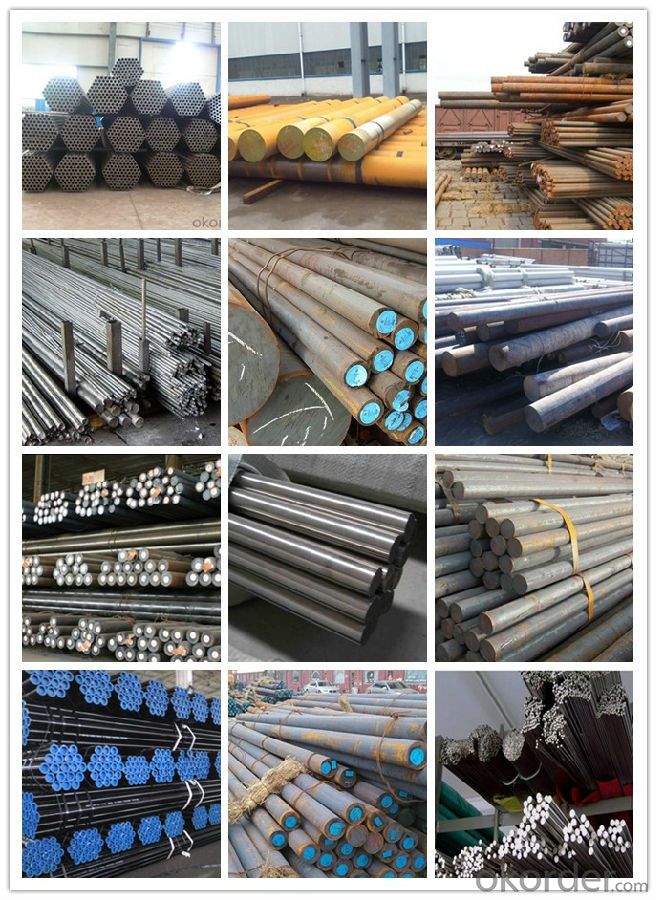

Product show

Work shop

Our Services

* Welcome to contact us with your detailed inquiry, you will be replied within 24 hours.

* You are promised to obtain the best quality, price and service.

* We'd like to provide samples for your confirm.

- Q: Is special steel resistant to wear and abrasion?

- Yes, special steel is known for its high resistance to wear and abrasion. It is specifically designed and formulated to withstand harsh conditions and prolonged usage without deteriorating or losing its strength.

- Q: How does special steel contribute to the manufacturing of oil and gas equipment?

- Special steel plays a crucial role in the manufacturing of oil and gas equipment due to its unique properties and characteristics that make it suitable for the demanding conditions of the industry. Firstly, special steel is known for its high strength and durability, which is essential in the production of oil and gas equipment. Equipment such as drilling rigs, pipelines, and storage tanks are subjected to extreme pressures, corrosive environments, and harsh weather conditions. Special steel, with its superior mechanical properties, can withstand these conditions and ensure the reliable and long-lasting performance of the equipment. Additionally, special steel offers excellent resistance to corrosion and oxidation, which are prevalent in the oil and gas industry. The presence of corrosive substances and the exposure to high temperatures can cause regular steel to deteriorate quickly. However, special steel is specifically designed to resist corrosion, ensuring that the equipment remains functional and safe for use over its lifetime. Furthermore, special steel can withstand high temperatures and pressure differentials, making it suitable for applications such as heat exchangers and pressure vessels. These components are vital in various oil and gas processes, including refining and transportation. The ability of special steel to handle extreme temperatures and pressures ensures the efficiency and safety of these operations. Special steel also contributes to the manufacturing of oil and gas equipment by providing excellent weldability and machinability. This allows for ease of fabrication and assembly, reducing production time and costs. The versatility of special steel enables manufacturers to design and create complex equipment that meets the specific requirements of the oil and gas industry. In conclusion, special steel plays a crucial role in the manufacturing of oil and gas equipment by providing high strength, durability, corrosion resistance, and the ability to withstand extreme temperatures and pressures. Its unique properties ensure the reliability, safety, and longevity of the equipment, making it an indispensable material in the oil and gas industry.

- Q: Can special steel be used in the manufacturing of household appliances?

- Yes, special steel can be used in the manufacturing of household appliances. Special steel offers enhanced strength, durability, and corrosion resistance, making it suitable for applications such as refrigerator compressors, oven heating elements, and washing machine drums.

- Q: Can special steel be used in the defense sector?

- Indeed, in the defense sector, special steel finds itself as a viable option. Special steel, which encompasses alloys or compositions designed with specific attributes such as high strength, hardness, resistance to corrosion, or heat resistance, proves to be suitable for a range of defense applications. These applications include the construction of armored vehicles, naval vessels, aircraft, and weaponry. Within the defense sector, special steel serves as a valuable resource for manufacturing components and structures necessitating exceptional strength and durability. For instance, it can be utilized to produce armor plates for tanks and armored vehicles, which must endure high impact and ballistic threats. Additionally, special steel can be employed in the construction of naval vessels, providing corrosion resistance and enhancing overall structural integrity. Furthermore, the defense industry heavily relies on special steel for manufacturing aircraft parts and weaponry. Aircraft components, such as landing gear, engine parts, and structural elements, demand materials of high strength to ensure safe and reliable operation. Special steel alloys fulfill this requirement by providing the necessary strength and resistance to extreme conditions, including high temperatures and pressures, making them an ideal choice for these applications. Moreover, special steel plays a vital role in the production of various types of weapons, such as firearms and blades. Its exceptional strength and hardness properties render it suitable for manufacturing gun barrels, bulletproof vests, and knives employed by military personnel. To summarize, special steel holds significant value within the defense sector due to its exceptional properties, including strength, hardness, corrosion resistance, and heat resistance. Its extensive applications in the construction of armored vehicles, naval vessels, aircraft, and weaponry ensure the safety, durability, and effectiveness of military equipment.

- Q: How does special steel contribute to the mining equipment industry?

- Special steel plays a significant role in the mining equipment industry by providing superior strength, durability, and resistance to harsh operating conditions. It is used in the manufacturing of various mining equipment components such as drill bits, crusher parts, conveyor belts, and buckets, enhancing their performance and longevity. Additionally, special steel enables the development of more advanced and efficient mining machinery, leading to increased productivity and safety in the mining sector.

- Q: How does special steel perform in pharmaceutical applications?

- Due to its unique properties and characteristics, special steel is highly sought after in pharmaceutical applications. Its exceptional corrosion resistance is especially important in pharmaceutical environments where chemical substances and aggressive cleaning agents are commonly used. This corrosion resistance ensures the steel remains durable and maintains its integrity over time. Furthermore, special steel is renowned for its strength and durability, making it suitable for applications that involve heavy loads or frequent use. This strength allows the steel to withstand the demanding requirements of pharmaceutical processes, such as mixing, grinding, and sterilization, without compromising its structural integrity. Another significant advantage of special steel in pharmaceutical applications is its hygienic properties. It is highly resistant to bacterial growth and easy to clean, making it perfect for environments where cleanliness and sterility are of utmost importance. The smooth surface of special steel prevents the accumulation of dirt, bacteria, and other contaminants, reducing the risk of contamination and ensuring the safety and quality of pharmaceutical products. Moreover, special steel offers excellent temperature resistance, enabling it to endure extreme temperatures and thermal cycling commonly encountered in pharmaceutical processes. This thermal stability guarantees that the steel retains its mechanical properties and dimensional stability, even under fluctuating temperature conditions. Overall, special steel's corrosion resistance, high strength, hygienic properties, and temperature resistance make it a trustworthy and versatile material for pharmaceutical applications. Its exceptional performance in these challenging environments contributes to the production of safe and high-quality pharmaceutical products.

- Q: What are the main characteristics of tool steel?

- Tool steel, a specialized type of steel, is specifically engineered for the manufacturing of tools such as drills, dies, and cutting instruments. It boasts several key attributes that render it suitable for these applications. Primarily, tool steel is renowned for its exceptional hardness. It contains a substantial amount of carbon, typically ranging from 0.5% to 1.5%, which contributes to its hardness. This hardness enables tool steel to withstand wear and abrasion, making it perfect for cutting and shaping materials. Another crucial characteristic of tool steel is its remarkable toughness. It possesses the ability to endure high impact and shock loads without fracturing or breaking. This toughness is vital in tooling applications where tools are subjected to heavy loads and forces. Tool steel also exhibits superb heat resistance. It possesses a high melting point, allowing it to retain its strength and hardness even at elevated temperatures. This heat resistance is essential in applications where tools are exposed to high temperatures during cutting or shaping processes. Furthermore, tool steel possesses excellent dimensional stability and machinability. It experiences minimal distortion and shrinkage during heat treatment, ensuring that the tool retains its shape and size. Additionally, tool steel is easily machined, enabling the production of intricate shapes and designs. Overall, the prominent characteristics of tool steel encompass high hardness, toughness, heat resistance, dimensional stability, and machinability. These properties establish tool steel as an ideal material for the production of tools that necessitate high strength, durability, and performance.

- Q: What is the difference between stainless steel and special steel?

- Stainless steel is a type of steel that contains a minimum of 10.5% chromium content, which helps it resist corrosion and staining. On the other hand, special steel refers to a wide range of steel alloys that are specifically designed and manufactured for specific applications or purposes, such as high-strength, heat-resistant, or wear-resistant properties. So, while stainless steel is a specific type of steel with corrosion-resistant properties, special steel encompasses various alloys tailored for specific needs.

- Q: Can special steel be used in the musical instrument manufacturing industry?

- Yes, special steel can be used in the musical instrument manufacturing industry. Special steel alloys such as stainless steel or nickel silver are often used in the production of certain musical instruments to enhance their durability, resistance to corrosion, and overall performance. These alloys provide specific tonal qualities and are commonly utilized in the manufacturing of components such as strings, valves, and instrument bodies.

- Q: What are the different surface hardening grades of special steel?

- Different surface hardening grades of special steel are available, each with specific characteristics and properties. Some commonly used grades include the following: 1. Case-hardening steels: These grades, typically low carbon steels, develop a hard outer layer while maintaining a softer core. Carburizing or nitriding processes introduce carbon or nitrogen into the steel surface. These steels are used in applications where wear resistance and toughness are necessary. 2. Tool steels: These grades are designed for cutting, forming, and shaping tools. Tool steels are known for their high hardness, wear resistance, and ability to retain a cutting edge even at high temperatures. Various types of tool steels, such as HSS, hot work steel, cold work steel, and plastic mold steel, are suitable for specific applications. 3. Stainless steels: These grades contain a minimum of 10.5% chromium, providing excellent corrosion resistance. Stainless steels can be hardened through precipitation hardening or martensitic transformation. They are commonly used in industries requiring resistance to corrosion and high temperatures, such as food processing, chemical, and medical industries. 4. High-strength steels: These grades offer exceptional strength and toughness. They often contain alloying elements like manganese, chromium, or nickel to enhance their mechanical properties. High-strength steels are commonly used in structural applications, automotive components, and heavy machinery. 5. Maraging steels: These grades are known for their high strength, toughness, and excellent resistance to fracture. Maraging steels achieve these properties through a unique aging process involving precipitation hardening. They find applications in aerospace, defense, and tooling industries. 6. Bearing steels: These grades are specially formulated to provide excellent wear resistance and durability for bearing applications. Bearing steels often contain alloying elements like chromium, molybdenum, and vanadium to enhance their mechanical properties and fatigue resistance. These examples represent the diverse range of surface hardening grades of special steel, each offering unique properties and characteristics. This allows for a wide range of applications across various industries.

Send your message to us

Hot Forged 1045 Carbon Round Steel Bar with black/turned/grinded

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords