Deformed Steel Bar BS4449 GR.460B GR.B500B

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Steel rebar

Price: FOB $475-535/MT

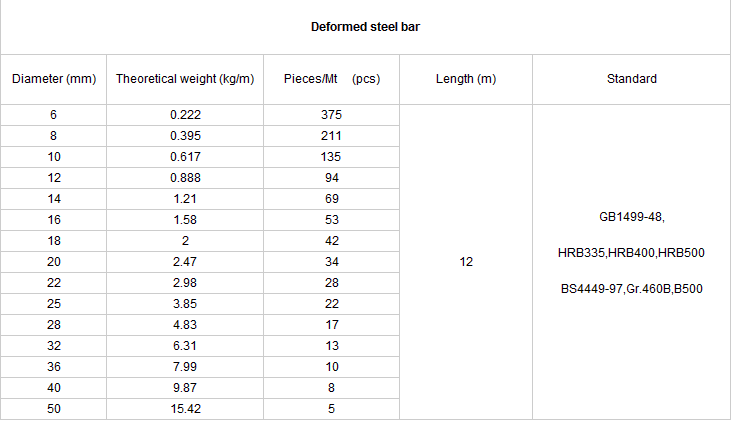

Size:6-50mm

Moq: 300tons of each size

Material: BS4449 GR460, ASTM A615, HRB400, HRB500

Steel rebar/deformed steel bar/reinforced steel bar

1.Standard: ASTM,BS,DIN,JIS,BS 4449 GR460B-1997. ASTM A615/706 GR 40/60, GB(HRB400,500)

2.Grade:HRB35, HRB400, HRB500,

3.Diameter:6-50mm

4.Length:6-12m and in coils

5.Place of Origin: Tangshan, China (Mainland)

6.Brand Name: CNBM

7.Material: cabon steel

8.Color: black

9.Packing: bundles or as per the buyers' requirement.

10. Minimum Order Quantity: 500 MTS as per size.

11. Payment terms: TT or LC at sight.

12. Delivery time: within 25-30 days after down payment or L/C received.

13. Application: Construction,Bridge Building, Road Building

- Q: Are there any limitations on the maximum spacing between steel rebars in concrete?

- Yes, there are limitations on the maximum spacing between steel rebars in concrete. These limitations are specified in building codes and standards. The maximum spacing is determined based on factors such as the structural requirements, load-bearing capacity, and the size and type of rebars used. These limitations ensure the structural integrity and durability of the concrete structure.

- Q: How are steel rebars handled and transported on construction sites?

- Steel rebars are typically handled and transported on construction sites using cranes, forklifts, or manual labor. They are usually bundled together and lifted using cranes or forklifts to designated areas. Workers may also carry smaller rebars manually. To keep them organized and prevent damage, rebars are often stored on racks or laid flat on the ground. Safety measures, such as wearing gloves and protective gear, are essential to ensure workers' well-being during the handling and transportation process.

- Q: Can steel rebars be used in architectural concrete elements?

- Yes, steel rebars can be used in architectural concrete elements. Steel rebars are commonly used in concrete construction to provide reinforcement and increase the strength and durability of the concrete structure. In architectural concrete, rebars can be strategically placed to enhance the structural integrity of the elements while also adding aesthetic value. The rebars can be exposed or hidden within the concrete, depending on the desired design outcome. By using steel rebars, architects have the flexibility to create complex and unique architectural elements while ensuring the required strength and stability.

- Q: What is the standard diameter of steel rebars?

- Steel rebars usually have a standard diameter that falls between 6 millimeters and 50 millimeters. The most frequently used diameters are 10 millimeters, 12 millimeters, 16 millimeters, and 20 millimeters. The choice of a particular diameter for a steel rebar depends on the specific application and the structural demands of the construction project. These rebars are commonly employed in reinforced concrete structures to bolster their tensile strength and overall endurance.

- Q: How long do steel rebars typically last before corroding?

- Steel rebars typically last for several decades before they start to corrode, depending on various factors such as the quality of the steel, environmental conditions, and the presence of protective coatings.

- Q: What is the minimum cover requirement for steel rebars in concrete?

- The minimum cover requirement for steel rebars in concrete is typically determined by building codes and structural design specifications. It can vary depending on factors such as the type of structure, environmental conditions, and the level of exposure to potential damage. However, a common guideline is to have a minimum cover of 1.5 inches (or 40 millimeters) for rebars in most reinforced concrete construction.

- Q: Can steel rebars be used in structures with high fire safety requirements?

- Yes, steel rebars can be used in structures with high fire safety requirements. Steel has a high melting point and good fire resistance properties, making it suitable for use in fire-resistant structures. Additionally, steel rebars can be encased in fire-resistant materials such as concrete or intumescent coatings to enhance their fire resistance capabilities.

- Q: Why is the price of screw steel affected by iron ore and coal?

- At the same time, rebar is the largest type of steel in our country and is the seller's market.

- Q: How do steel rebars affect the overall noise insulation of a structure?

- Steel rebars, being highly conductive materials, have a minimal impact on the overall noise insulation of a structure. They do not provide significant soundproofing properties and may even contribute to the transmission of sound waves through vibrations. To achieve effective noise insulation, additional soundproofing materials such as insulation boards or acoustic panels should be used alongside steel rebars.

- Q: What is the average weight of a steel rebar?

- The weight of a steel rebar can vary depending on its size and length. Typically, steel rebars are sold in lengths of 20 feet and are available in various diameters ranging from 3/8 inch to 1 1/4 inch. To determine the average weight, one needs to consider the density of steel, which is approximately 0.2836 pounds per cubic inch. The weight of a steel rebar can be calculated by multiplying its volume (pi times the diameter squared divided by 4, multiplied by the length) by the density of steel. Let's take a 1/2 inch diameter rebar with a length of 20 feet as an example. The calculation would be as follows: 1. Convert the diameter to inches: 1/2 inch = 0.5 inches 2. Calculate the volume: (pi * 0.5^2) / 4 = 0.19635 cubic inches 3. Convert the length to inches: 20 feet = 240 inches 4. Multiply the volume by the length: 0.19635 cubic inches * 240 inches = 47.04 cubic inches 5. Multiply the volume by the density of steel: 47.04 cubic inches * 0.2836 pounds per cubic inch = 13.34 pounds Hence, the average weight of a 1/2 inch diameter steel rebar with a length of 20 feet is approximately 13.34 pounds.

Send your message to us

Deformed Steel Bar BS4449 GR.460B GR.B500B

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords