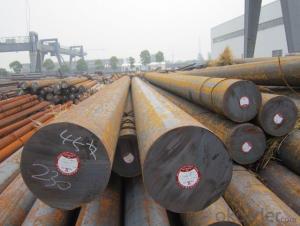

SKD11 Hot rolled steel rod price,1.2379 steel round bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Mild Steel Round Bar Q235 Q345 Q355

Name | SAE1045 Carbon Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | seaworthy packaging or as per customer's packing instruction |

Chemical Composition

C | Si≤ | Mn≤ | P≤ | S≤ | Cr | Mo | V |

1.40~1.60 | 0.4 | 0.6 | 0.030 | 0.030 | 11.0~13.0 | 0.80~1.20 | 0.20~0.50 |

Features of skd11 steel

(1) Good quenching resistance, heat deformation small, wear-resistant, impact resistant.

(2) Vacuum degassing refining processing pure steel.

(3) Spheroidizing softening process, good cutting performance.

(4) Strengthen the elements vanadium, molybdenum special join, is extremely excellent in wear resistance.

Packaging & Delivery

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Product Show

Workshop

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q:What are the challenges in welding special steel alloys?

- Welding special steel alloys poses several challenges due to their unique properties and composition. Some of the main challenges in welding special steel alloys include: 1. High melting point: Special steel alloys often have higher melting points compared to regular steel, which requires higher heat input during the welding process. This can result in difficulties in achieving proper fusion and may require specialized welding equipment and techniques. 2. Thermal expansion mismatch: Special steel alloys may have different coefficients of thermal expansion compared to the base metal or other materials being joined. This can lead to the formation of stress and distortion during welding, which can affect the structural integrity of the welded joints. 3. Sensitivity to heat: Certain special steel alloys are more susceptible to heat-affected zone (HAZ) cracking and other forms of weld defects. The high heat input during welding can cause the formation of brittle phases or precipitates, leading to reduced mechanical properties and potential weld failures. 4. Metallurgical changes: Welding special steel alloys can result in significant metallurgical changes in the base metal and the heat-affected zone. These changes include the formation of new microstructures, changes in hardness, and variations in the chemical composition. These alterations can impact the overall performance and properties of the welded joints. 5. Pre-weld and post-weld treatments: Special steel alloys often require specific pre-weld and post-weld treatments to minimize the risk of weld defects and optimize the properties of the welded joints. These treatments may include preheating, post-weld heat treatment, or the use of specialized filler metals to ensure proper weld integrity. 6. Limited availability of consumables: Special steel alloys may have limited availability of suitable consumables, such as filler metals and shielding gases, which are essential for achieving quality welds. The lack of appropriate consumables can make it challenging to find compatible materials that can provide adequate strength and corrosion resistance in the welded joints. To overcome these challenges, it is crucial to have a thorough understanding of the specific properties and requirements of the special steel alloy being welded. Proper welding techniques, including heat control, filler material selection, and post-weld treatments, should be employed to ensure high-quality welds with optimal mechanical properties and structural integrity. Additionally, collaboration with material suppliers, welding experts, and adherence to industry standards and guidelines can help address the challenges associated with welding special steel alloys effectively.

- Q:How is special steel used in the telecommunications supply chain?

- Special steel is used in the telecommunications supply chain for various applications. It is commonly used in the manufacturing of infrastructure components such as transmission towers, antenna supports, and cable trays. The high strength and durability of special steel make it suitable for withstanding extreme weather conditions and ensuring the stability and reliability of telecommunications networks. Additionally, special steel is also used in the production of cables, connectors, and other equipment that require corrosion resistance and electrical conductivity, contributing to the efficient transmission of signals in the telecommunications industry.

- Q:How is magnetic stainless steel used in the production of magnetic components?

- Magnetic stainless steel is used in the production of magnetic components due to its unique properties. It possesses both the corrosion resistance of stainless steel and the magnetic properties required for applications such as motors, transformers, and magnetic assemblies. The steel is typically alloyed with elements like nickel, manganese, and nitrogen, which enhance its magnetic properties. This allows for the manufacturing of reliable and efficient magnetic components that are resistant to rust and can withstand harsh environments.

- Q:Can special steel be used in the agricultural equipment manufacturing industry?

- Yes, special steel can be used in the agricultural equipment manufacturing industry. Special steel, such as high-strength or wear-resistant steel, can enhance the durability, strength, and performance of agricultural equipment, making it suitable for various applications in the industry.

- Q:Is the steel column of the steel structure HM a special steel?

- The mid flange H section steel HM (M for Middle English prefix) in GB/T 112631998 this standard inside, not special steel;

- Q:How does special steel perform in forging applications?

- Special steel is highly desirable for forging applications due to its exceptional strength, durability, and resistance to wear and tear. It offers superior performance as it can withstand the intense heat and pressure involved in the forging process without losing its shape or integrity. Additionally, special steel's unique composition allows for precise shaping and intricate designs, making it an ideal choice for complex forging projects.

- Q:Can special steel be used in marine applications?

- Marine applications can indeed utilize special steel. This type of steel, also referred to as marine grade steel, is specifically engineered to endure the demanding conditions found in marine environments. It possesses exceptional qualities, including heightened resistance to corrosion, increased strength, and enhanced durability, which render it suitable for a wide range of marine applications. The construction of ships, offshore structures, and marine equipment commonly employs special steel. Its capacity to withstand corrosion from saltwater, chemicals, and other environmental factors makes it an excellent choice for marine applications. Additionally, special steel finds use in the production of propellers, shafts, and other components that necessitate high tensile strength and fatigue resistance. All in all, special steel proves to be a dependable and efficient material for marine applications due to its unique properties and ability to withstand the challenges presented by the marine environment.

- Q:What is special steel? What is special steel?

- However, special steel refers to stainless steel, other special steel plate, such as automobile steel plate and military steel plate, etc., stainless steel is divided into austenite and ferrite, such as 304316410439 stainless steel varieties. According to the specific use of stainless steel quality, such as 409L can be used as a container, microwave oven and elevator industry, 304 can be used as medical devices. The market prospect is not an ordinary person can predict, domestic steel prices are monthly pricing, big companies such as Baosteel, TISCO, Zhangjiagang Pohang. Lead the trend of special steel prices.

- Q:How does special steel perform in abrasive wear conditions?

- Special steel performs well in abrasive wear conditions due to its high hardness and toughness. It has excellent resistance to abrasion, which allows it to withstand the rubbing, scraping, and grinding that occurs in abrasive environments. The unique composition and heat treatment of special steel enhance its ability to resist wear and maintain its structural integrity, making it an ideal choice for applications where abrasive wear is a concern.

- Q:How is duplex stainless steel used in the oil and gas industry?

- Duplex stainless steel is extensively used in the oil and gas industry due to its exceptional properties. It is commonly employed in the construction of pipelines, offshore platforms, and various equipment. Its high corrosion resistance allows for reliable performance in aggressive environments, such as offshore drilling rigs and subsea equipment. Additionally, its high strength and toughness make it suitable for handling high-pressure and high-temperature conditions. Overall, duplex stainless steel plays a crucial role in ensuring the safety, efficiency, and longevity of oil and gas operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SKD11 Hot rolled steel rod price,1.2379 steel round bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords