Decorative Wood Veneers Melamine Molded Door Skin

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 45000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details of the Melamine Molded Door Skin

| Thickness | 4.5mm | |||

| Height | 2150mm | |||

| Door skin | 770mm | 870mm | 920mm | 1020mm |

| Pattern | 460mm | 460mm | 560mm | 560mm |

| MOQ | 180pcs | 180pcs | 180pcs | 180pcs |

| N.W | 6.3KG | 7.1KG | 7.5KG | 8.3KG |

Specifications of the Melamine Molded Door Skin

1) Density: above 850 kg/m3

2) Moisture: 6 - 12%

3) Water absorption rate: <20%

4) Modulus of elasticity: ≥35Mpa

5) Tolerance:Length/width<2.0mm; thickness<0.2mm

Instruction of the Melamine Molded Door Skin

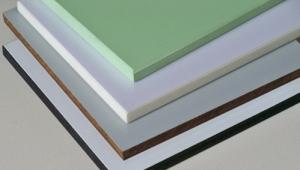

The Melamine Molded Door Skin is mould the high density fiberboard to be raised panel with melamine surface

under high temperature and pressure with advanced technolony. No shrink, no split, great compatibility. Elegant

style makes it fresh and classic.

The price of the Melamine Molded Door Skin

1) the price depends on the size and veneer, having nothing to do wih the designs.

2) the price of size 920mm&960mm (width) maybe a little cheaper if there is smaller size to go with them for the same order.

The following pictures are for reference

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- much better. the reason is simple. Should be natural for his natural growth without being controlled. The lines will be natural.

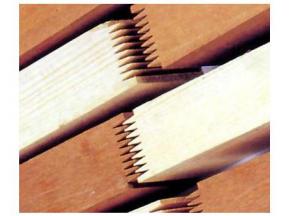

- Q: Cut Slicing - The cut is a round of vertical cut logs, producing a veneer with a ruled ridge.

- To cut the oak-like wooden vines at a slight angle, to minimize the appearance of "scales" of wood grain, to produce a ruled veneer.

- Q: Slicing of thin slices of wood

- after cooking treatment; the cooking process should be reduced to more than 40 ℃, it should slow down the heating rate

- Q: The following table lists the cooking criteria for several types of wood,

- intermittent operation of the drying room. Drying room is old-fashioned drying equipment, very economical, but dry quality is better.

- Q: Technology veneer and natural veneer distinction

- This is the case all over the world. This is not to say. All understand. Technology veneer although there is no natural veneer texture naturally nice.

- Q: Wooden door with veneer ruled, pattern is produced by different cutting methods

- Plain Slicing (Flat Slicing, Flat cut) - also known as flat cut, flat slices / plain film, string cut veneer is the section of the knife along the center of the parallel line

- Q: What is veneer, please explain in detail

- Veneer; veneer; hereinafter referred to as veneer) and its veneer decoration industry started in the last century 50's,

- Q: Veneer should pay attention to the different production processes

- the process is complicated, the general enterprise does not understand, the speculation also naturally increases.

- Q: The Production process of cooking

- The following table lists the cooking criteria for several types of wood, for reference only.

- Q: Veneer has a very affordable, versatile features

- Can be decorated according to the needs of people to produce different models and styles of the skin.

Send your message to us

Decorative Wood Veneers Melamine Molded Door Skin

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 45000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords