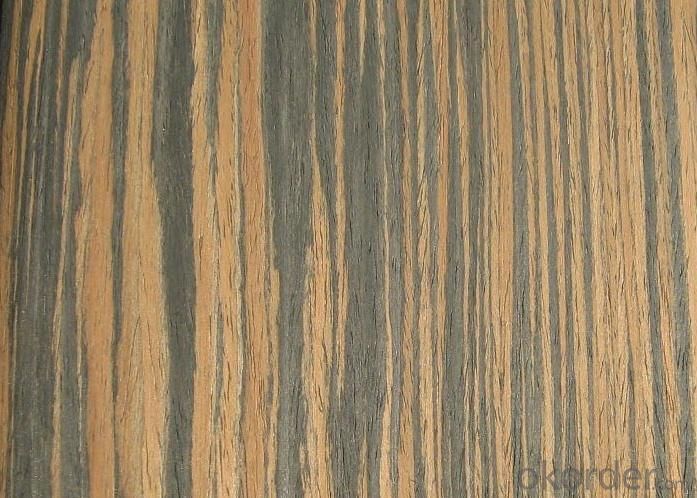

Zebra Engineered Wood Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the Zebra Engineered Wood Veneer

|

Name |

Zebra Engineered Wood Veneer |

|

Size |

Length:2500-3100mm,width:640mm |

|

Thickness |

0.3-0.6mm |

|

Grade |

A/A,A/B, A or as agreed |

|

Morsture |

to be 8-12% at time of shipment |

|

Character |

as above |

|

Cutting |

sliced/rotary cut |

|

Usage |

furniture, hotel furniture, laminate flooring |

|

Package |

standard exporting package |

|

Delivery time |

15days on receipt deposit or original L/C |

|

MOQ |

20 square/ meter |

Instruction of the Zebra Engineered Wood Veneer

Zebra Engineered is a sliced reconstructed real wood veneer, it is made from nature timber which color is

enhanced, reformed to a square "log" and then re-sliced into rectangular veneer sheets.

The usage of the Zebra Engineered Wood Veneer

The engineered veneer is applicable for modern new decoration and traditional classic decoration. Various types

and colors meet the increasing individual consumption needs of people. There is at least one type suitable for

your selection. The engineered veneer saves your material cost on residential decoration and prevents you from

troubles of difficult and impossible connection resulted from texture and color of natural wood. You can make

good use of each raw material that youve bought.

Presently, Zebra Engineered Wood Veneer has mainly developed following technical woods of white oak series,

red oak series, ebony series, red sandalwood series, soluble red wood series, zebra series, cherry series, walnut

series, wenge series, maple series, burl series, beech series and rose wood series. Several series and tens of types

have been promoted to the market and hundreds of types are in our technical storage.

The following pictures for your reference.

- Q: Veneer production process is this?

- After the wood side has been cooked (ie, water heat treatment), the plasticity of the wood increases

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- much better. the reason is simple. Should be natural for his natural growth without being controlled. The lines will be natural.

- Q: The Veneer dyeing quality requirements

- after the factory processing bleach (usually takes about 6 hours, how many times to see the wood) is the purpose of color uniform

- Q: Cut Slicing - The cut is a round of vertical cut logs, producing a veneer with a ruled ridge.

- Lengthwise Slicing - Cut the flat saws flat through the fixed slicer and cut the veneer from the bottom of the plate. The texture of the longitudinal cut veneer is varied.

- Q: Part of the production process

- The most effective way to improve the plasticity of wood is to adjust both the temperature and the moisture content at the same time to increase the temperature of the wood while increasing the moisture content of the wood.

- Q: Brief description of veneer production process

- Of the wooden side should be promptly placed in the paver before the wood temperature of the tank, the insulation in the range of 40 ~ 50 ℃ (with the species and thin wood thickness may be).

- Q: What is the veneer panel

- made by the adhesive process made with a single decorative effect of the decorative plate

- Q: The Production process of cooking

- First, the wooden side into the cooking pool, the tree species, wooden specifications should be carried out separately;

- Q: Different cutting processes of wood veneer

- Finally, the term "technology veneer" can not accurately express the essence of the product, and it is easy to misunderstand. In foreign countries, "technology wood" is generally referred to as "landscaping", "reorganized wood" or "combination Wood "

- Q: The Sliced ??veneer manufacturing process

- The width of the veneer is not less than the relevant requirement.

Send your message to us

Zebra Engineered Wood Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords