Mahogany Oak Engineered Wood Veneers

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the Oak Engineered Wood Veneer

| Name | Oak Engineered Wood Veneer |

| Type | sliced |

| Length | 2200-3100mm |

| Width | 320-900mm |

| Thickness | 0.15-1mm |

| Thickness tolerance | 0.02mm |

| Grade | A/A Grade |

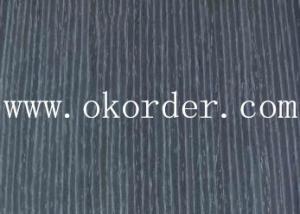

Instruction of the Oak Engineered Wood Veneer

Oak Engineered Wood Veneer is sliced reconstructed real wood veneer, it is made from nature

timber which color is enhanced,reformed to a square and then re-sliced into rectangular veneer

sheets.

The usage of the Oak Engineered Wood Veneer

The engineered wood veneer is applicable for modern new decoration and traditional classic

decoration. And now the engineered wood veneer has mainly developed the following techinical

wood of white oak serious, red oak serious, ebony serious, res sandalwood serious,soluble red

wood serious,zebra serious, cherry serious, walnut serious,wenge serious, and so on. Several

serious and ten of types have been promoted to the markets and hundreds of types are in our

technical storage.

Popular of the Oak Engineeres Wood Veneer

Various types and colors of the The oak engineered wood veneer meet the increasing

individual consumption needs of people. There is at last one type suitable for your selection,

the engineered wood veneers saves your material cost on residential decoration and prevents

you from the trouble of difficult and impossible connection resulted from texture and color of

nature wood. You can make good use of each raw material that you bought.

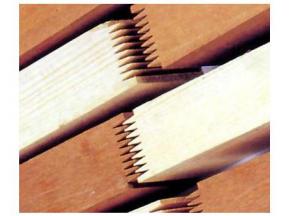

The following pictures for your reference.

- Q: Veneer production process is this?

- The use of these saws to produce veneer, the board rate is high, the quality of thin wood is better, chopper machine is more efficient.

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- This is the technology can not be veneer. Talk about the technology veneer. The reason why there will be technology veneer that should be a shortage of wood. Not just China.

- Q: Slicing of thin slices of wood

- after cooking treatment; the cooking process should be reduced to more than 40 ℃, it should slow down the heating rate

- Q: The principle of veneer dyeing

- in the preservation of natural veneer original natural texture and texture at the same time, the veneer dyeing, so rich Color and wood texture with a different decorative effect

- Q: What is veneer, please explain in detail

- after half a century of development, already have a considerable scale.

- Q: What is the veneer panel

- It is a special way to exist the plywood, the thickness of 3mm, a good panel can even reach 5mm, but the market is mostly 2.5-2.8mm.

- Q: Veneer should pay attention to the different production processes

- But the technology veneer is widely recognized by the furniture industry still need time, science and technology on the wood of many misunderstandings, are the lack of factual basis, is the understanding of the errors.

- Q: Different cutting processes of wood veneer

- Technology wood mainly to natural ordinary wood or artificial Planted fast-growing forest as raw material, processed and processed, and natural precious veneer similar ...

- Q: What are the quality items of veneer piles?

- by the bark part is later growth, material color deep, Dense, hard material, said latewood (autumn wood, summer material)

- Q: What is the size of the veneer?

- , imports of veneer up to 3 meters long. Width is generally more than 9 cm wide natural.

Send your message to us

Mahogany Oak Engineered Wood Veneers

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords