Ebony Wood Veneers Engineered

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

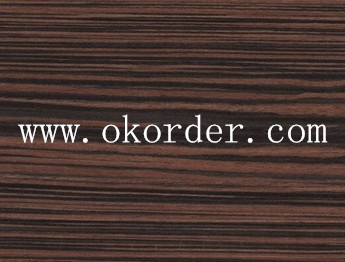

Specifications of the Ebony Engineered Wood Veneer

| Name | Teak Engineered Wood Veneer |

| Type | sliced |

| Length | 2200-3100mm |

| Width | 320-900mm |

| Thickness | 0.15-1mm |

| Thickness tolerance | 0.02mm |

| Normal size | 2500*640*0.5mm |

Packing details of the Ebony Engineered Wood Veneer

Normal loaded: 18 pallets/20'FCL, 36 pallets/40'FCL

Packing size: 2520*650*650mm

Instruction of the Ebony Engineered Wood Veneer

Teak Engineered Wood Veneer is sliced reconstructed real wood veneer, it is made from nature

timber which color is enhanced,reformed to a square and then re-sliced into rectangular veneer

sheets.

The usage of the Ebony Engineered Wood Veneer

The engineered wood veneer is applicable for modern new decoration and traditional classic

decoration. And now the engineered wood veneer has mainly developed the following techinical

wood of white oak serious, red oak serious, ebony serious, res sandalwood serious,soluble red

wood serious,zebra serious, cherry serious, walnut serious,wenge serious, and so on. Several

serious and ten of types have been promoted to the markets and hundreds of types are in our

technical storage.

Popular of the Ebony Engineered Wood Veneer

Various types and colors of the The teak engineered wood veneer meet the increasing

individual consumption needs of people. There is at last one type suitable for your selection,

the engineered wood veneers saves your material cost on residential decoration and prevents

you from the trouble of difficult and impossible connection resulted from texture and color of

nature wood. You can make good use of each raw material that you bought.

The following pictures for your reference.

- Q: Veneer production process is this?

- This is the actual production is usually used saturated steam or hot water on the wood side of the cooking treatment of a water heat treatment reasons

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- In personal terms. Science and technology veneer in the next few years will be to a certain extent, replace the natural veneer. hope this helps. Pure hand hope to give points. You can also ask

- Q: Often, the processing of natural vines is done by slicing the method. The process flow is as follows

- Different diameter logs should use different sawing programs. The thick lines in the figure are the saw lines, and the direction of the arrows is the planing direction of the planer:

- Q: A lot of Advantages of veneer

- Apply white glue to the surface of the applied wood. The veneer will be affixed to the surface of the wood, and plastic scraper along the veneer lines scrape out the bubble

- Q: The principle of veneer dyeing

- in the preservation of natural veneer original natural texture and texture at the same time, the veneer dyeing, so rich Color and wood texture with a different decorative effect

- Q: What is veneer, please explain in detail

- its development is by leaps and bounds, the emergence of a large number of industry experts

- Q: Different veneer has different production processes

- Most furniture companies believe that science and technology veneer is not a native wood, but what is it, they also do not know, or simply called "artificial veneer".

- Q: The Production process of cooking

- First, the wooden side into the cooking pool, the tree species, wooden specifications should be carried out separately;

- Q: Veneer has a very affordable, versatile features

- With the current shortage of natural timber resources, as well as the price of high-grade tree species is climbing

- Q: What are the quality items of veneer piles?

- Each year round, by the pith part of the annual growth season is the initial formation, material color is shallow, loose tissue, material soft, called early wood (spring wood)

Send your message to us

Ebony Wood Veneers Engineered

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords