Decorative Continuous Casting Aluminum Sheets for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

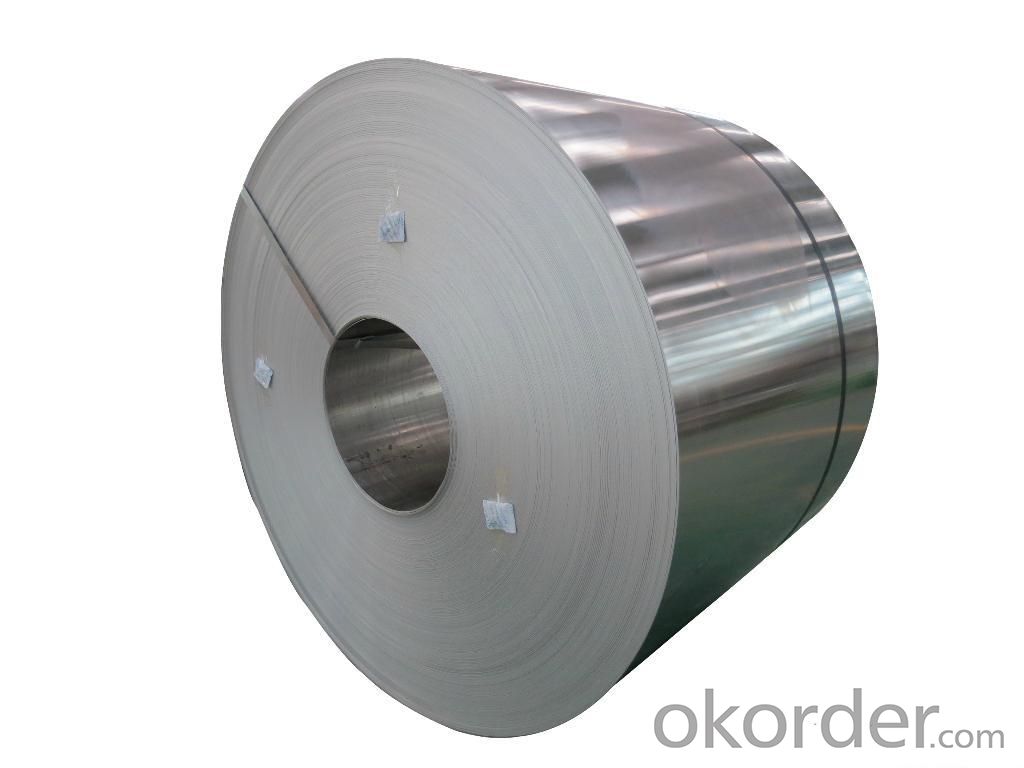

1.Structure of Continuous Casting Aluminium Coils

Continuous Casting Aluminium Strip in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coils

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Style | Thickness | Width |

| AA1100 | H14 | Continuous Casting | 0.2mm-3mm | 1000mm-1500mm |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets are prone to warping, especially when exposed to high temperatures or subjected to excessive pressure. However, the extent of warping depends on various factors such as the thickness of the sheet, the specific alloy used, and the conditions it is exposed to.

- Q: What are the different methods of bending aluminum sheets?

- There are several methods of bending aluminum sheets, including air bending, press brake bending, roll bending, and stretch forming.

- Q: 5083 what is the density of the aluminum plate?

- 5083 aluminum alloy is Al-Mg-Si, use a wide range, especially in the construction industry cannot do without this alloy, alloy is the most promising. The main alloying elements as magnesium, has good forming performance, corrosion resistance, weldability, moderate intensity, is a kind of pure aluminum alloy aluminum density: 2.71 tons. / m3 (g / cm3) alloy aluminum density: 2.8 tons / m3 (g / cm3) antirust aluminum density: 2.73 tons / m3 (g / cm3)

- Q: HI! I have a few of my most favorite aluminum baking pans and lids that are brown with baked on grease etc...and I have not the strength or endurance to stand and buff them with a scratchy pad til they gleam....are there any cleaning chems or soaps that will do this for me?? Thanks!! Mama never told me there'd be days like this!

- Do you want the lecture why you shouldn't be using aluminum utensils to cook with? Aluminum leeches out and is associated with dementia, birth defects, and heavy metal poisoning. In future, line your baking pans with parchment paper for 1) easy clean up and 2) to prevent metal leeching. Okay, now how to clean-to-gleam without scrubbing (which is pretty close to impossible). Method 1: Put your empty pans on the stove and heat them up until they are super hot (a baking sheet will need to cover two burners). Once they are really hot, stand back and pour water in them. This should at least loosen all the crud so you only need to to minimal swishing to remove most of it. Method 2: Put boiling water in your sink, a good dishwashing liquid such as Dawn de-greaser, and let your pans sit for an hour or so. Neither method will get your pans gleaming, only scrubbing will do that. But again, you don't want to scrub as you are then wearing away the surface of the metal which leads to more leeching. Many chemicals react negatively with aluminum, leaving dark stains on the metal. Mama never told you there'd be days like this because she thought you'd get yourself a set of stainless-steel Revereware cookware. Seriously, consider dumping all your aluminum (not just because of easy clean up, but for health) and replacing with stainless, glass, or steel or porcelain-coated. I know, standard baking sheets ALWAYS come in aluminum unless you're Gordon Ramsay and can afford over-the-top-quality stuff, so this is why god invented parchment paper.

- Q: Can aluminum sheet be used for signage?

- Yes, aluminum sheet can be used for signage. Aluminum is a popular choice for signage due to its durability, versatility, and cost-effectiveness. It is a lightweight material that is resistant to corrosion, making it suitable for both indoor and outdoor signage. Aluminum sheet can be easily cut, shaped, and formed into various sizes and designs, allowing for customizable signage options. Additionally, aluminum can be easily printed or engraved upon, making it ideal for displaying text, graphics, and logos. Its sleek and professional appearance adds to its appeal for signage purposes. Overall, aluminum sheet is an excellent choice for signage due to its durability, versatility, and aesthetic qualities.

- Q: Is it possible to incorporate recycled aluminum sheets into a construction project?

- <p>Yes, you can use recycled aluminum sheets in your building project. Recycled aluminum is not only environmentally friendly but also cost-effective. It maintains the same strength and durability as new aluminum, making it suitable for various construction applications such as roofing, siding, and structural components. Ensure that the recycled aluminum meets the required standards and specifications for your project to guarantee safety and performance.</p>

- Q: Can aluminum sheets be easily shaped or bent?

- Yes, aluminum sheets can be easily shaped or bent due to their malleability and low density.

- Q: What is the classification of 6061106070 aluminum plate, which respectively represent what it means to ask God for help

- Three, the beginning of the aluminum manganese alloy, 3003, 3004, 3015 and so on, the use of a wide range, also known as rust aluminum. Four, the beginning of the four Department of aluminum is aluminum silicon alloy, on behalf of 4A01 five, the beginning of the aluminum magnesium alloy, there are 5052, 5083 and so on, the use of more than three series, the domestic manufacturers can do.

- Q: What is the melting point of 101 aluminum sheets?

- The melting point of 101 aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: I heard somewhere that when aluminum is heated, it releases something that is a known cause of Alzheimers. Is this true? I have a homemade cooker made of aluminum and I don't want Alzheimers.

- Aluminium and aluminium compounds are ubiquitous and we consume up to 50mg a day. The fact that aluminium is present isn't necessarily an indication that it is the cause of Alzheimers, and the consensus is that there are a combination of factors at play including genetic factors. However, there has been research which reveals amyloid plaques, which are protein compounds and aluminium and tangled synapses, which are part of the neuronal network. This is leading researchers to suspect that there is a causal link.

Send your message to us

Decorative Continuous Casting Aluminum Sheets for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords