Outdoor Architectural Aluminum Sheets for Continuous Casting Aluminum Car Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Continuous Casting Aluminium Sheet for Car Trailer

Continuous Casting Aluminium Sheet for Car Trailer is one semi-finished aluminium material. This sheet can be cut to size you wanted in production. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Continuous Casting Aluminium Sheet for Car Trailer

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Continuous Casting Aluminium Sheet for Car Trailer

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Continuous Casting Aluminium Sheet for Car Trailer

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Continuous Casting Aluminium Sheet for Car Trailer

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

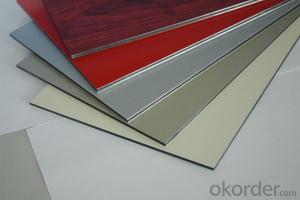

6. Image of Continuous Casting Aluminium Sheet for Car Trailer

7. Package and shipping of Continuous Casting Aluminium Sheet for Car Trailer

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheet withstand heavy loads?

- Yes, aluminum sheet can withstand heavy loads. Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications that require durability and load-bearing capabilities. Aluminum sheets are commonly used in industries such as aerospace, automotive, construction, and marine, where heavy loads are involved. Additionally, aluminum's inherent corrosion resistance further enhances its ability to withstand heavy loads over extended periods. However, it is important to consider the specific grade and thickness of the aluminum sheet, as different alloys and thicknesses have varying load capacities.

- Q: This question asks for an explanation of the various types of paint that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with different types of paints to enhance their appearance, durability, and functionality. The common types include: 1) Acrylic Paints: Known for their flexibility and resistance to weathering and UV rays. 2) Polyester Paints: These offer excellent adhesion and gloss. 3) Epoxy Paints: Known for their chemical resistance and durability. 4) Polyurethane Paints: They provide a tough, scratch-resistant finish. 5) Powder Coatings: These are electrostatically applied and offer a durable, weather-resistant finish. 6) Fluoropolymer Coatings: They provide excellent resistance to chemicals and UV degradation. Each type has specific properties that make it suitable for different applications and environments.</p>

- Q: Can aluminum sheets be used in the automotive industry?

- Yes, aluminum sheets can be used in the automotive industry. Aluminum is a lightweight and durable material that offers several advantages in automotive manufacturing. It is commonly used in the production of car bodies, hoods, doors, and other structural components. The use of aluminum sheets in automobiles helps to reduce the weight of the vehicle, enhancing fuel efficiency and improving performance. Additionally, aluminum has excellent corrosion resistance properties, which is crucial for vehicles exposed to harsh weather conditions. Furthermore, aluminum sheets can be easily formed, welded, and joined, making them versatile and suitable for various automotive applications. Overall, the automotive industry widely embraces the use of aluminum sheets due to their numerous benefits.

- Q: Can aluminum sheets be easily shaped or bent?

- Yes, aluminum sheets can be easily shaped or bent. Aluminum is known for its excellent malleability and ductility, which allows it to be easily formed into various shapes and bends. It can be manipulated using a variety of techniques such as rolling, pressing, or even using hand tools. The malleability of aluminum makes it a preferred choice in industries such as automotive, aerospace, and construction, where it is commonly used in the production of parts and structures that require complex shapes and bends. Additionally, aluminum's lightweight and corrosion-resistant properties further contribute to its suitability for shaping and bending processes.

- Q: Can aluminum sheets be used in outdoor environments?

- Yes, aluminum sheets can be used in outdoor environments. Aluminum is a highly versatile and durable material that is well-suited for outdoor applications. It has excellent resistance to corrosion, which makes it ideal for withstanding the elements such as rain, snow, and UV radiation. Additionally, aluminum sheets are lightweight yet structurally strong, making them suitable for various outdoor projects such as roofing, siding, and cladding. Furthermore, aluminum is non-combustible, making it a safe choice for outdoor environments. Overall, aluminum sheets provide a reliable and long-lasting solution for outdoor applications.

- Q: on the metal activity series, aluminum sits between magnesium and zinc, and all three sit above hydrogen. Explain why aluminum typically reacts only slowly with dilute acids even though both magnesium and zinc react rapidly

- Aluminum metal reacts with oxygen in the air to form a very tightly bonded aluminum oxide on its surface which slows the attack of acids trying to make contact with the aluminum atoms below the surface.

- Q: Can aluminum sheets be powder coated?

- Yes, aluminum sheets can be powder coated.

- Q: Can aluminum sheets be used for decorative wall panels?

- Yes, aluminum sheets can be used for decorative wall panels. Aluminum is a versatile material that offers a wide range of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it suitable for both interior and exterior applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for endless design possibilities. Additionally, aluminum can be powder-coated or anodized to enhance its appearance and provide additional protection against wear and tear. Whether it's for residential or commercial spaces, aluminum sheets can add a modern and stylish touch to any wall, making them a popular choice for decorative wall panels.

- Q: Are aluminum sheets suitable for use as materials for windows and doors?

- <p>Yes, aluminum sheets can be used for windows and doors. They are known for their durability, low maintenance, and resistance to corrosion and weathering. Aluminum windows and doors are energy-efficient, lightweight, and offer excellent security. They can also be easily customized in terms of size and design, and are often used in modern architecture for both residential and commercial buildings.</p>

- Q: What are the different types of coatings applied to aluminum sheet?

- There are several types of coatings that can be applied to aluminum sheets. Some common ones include anodizing, powder coating, and organic coatings. Anodizing involves creating an oxide layer on the surface of the aluminum, providing corrosion resistance and enhancing durability. Powder coating involves applying a dry powder to the aluminum surface and then curing it to create a protective and decorative layer. Organic coatings, such as paints or lacquers, can be applied to aluminum sheets to provide color, protection, and aesthetic appeal.

Send your message to us

Outdoor Architectural Aluminum Sheets for Continuous Casting Aluminum Car Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords