Customized Color Aluminum Coated Coils for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

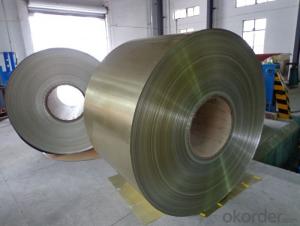

1. Structure of Plain Aluminium Coils for Different Usages Our aluminum Coils are widely used in solar energy curtain wall. It integrates a photo-voltaic system. Photovoltaic panels are usually installed on the glass of curtain wall to generate electricity from solar energy. Plain Aluminium Coils for Different Usages can meet the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209. 2.Main Features of Plain Aluminium Coils for Different Usages •High intensity •Easy to be processed and shaped •Weather resistance •Anti-pollution & environment protection 3. Plain Aluminium Coils for Different Usages Images 4.Specification of Plain Aluminium Coils for Different Usages Alloy: AA1×××; AA3×××; AA5×××; AA8××× Temper: H14; H16; H18; H22; H24; H26; H32; O; F Thickness: 0.2mm-100mm Width: 30mm-1700mm Standard: GB/T 3880-2006 5.FAQ A.What about inspections to guarantee quality? For each order for Aluminum Coils, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods. With requirement of customers, we also can arrange the third party inspection. B.What about delivery? We will put order for Aluminum Coils in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity. C.What is the MOQ? 5 tons for each size. D. Where have you exported aluminium Coils? We have exported aluminum Coils to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Cost of aluminium coil coating fluorocarbon paint?

- Metal aluminum coil fluorocarbon paint that you don't know, Party A has no life, specific indicators of fluorine content in the product price between 120-180 GB / kg (according to different prices in different colors, the price from low to high color from shallow to deep) per kilogram spraying 3-5 square meters (according to the construction process and the environment skilled workers, such as spraying area under the influence of objective factors) warranty period for more than 15 years, GB product prices between 80-150.

- Q: Are there any restrictions on the coil thickness of aluminum coils?

- Yes, there are certain restrictions on the coil thickness of aluminum coils. The thickness of aluminum coils may vary depending on the specific application and manufacturing process. However, it is generally limited by practical constraints such as the equipment capabilities, handling and transportation considerations, and the desired properties of the final product.

- Q: What are the different types of aluminum alloy used in coil production?

- In coil production, various aluminum alloys are utilized, each possessing distinct properties and characteristics. Commonly employed in the production of coils are the following aluminum alloys: 1. The 1100 Aluminum Alloy is renowned for its exceptional corrosion resistance, high thermal conductivity, and electrical conductivity. It finds frequent application in areas where strength is not the primary concern, such as food and beverage packaging. 2. The 3003 Aluminum Alloy is frequently employed in coil production due to its moderate strength and excellent formability. It is commonly used in roofing and siding applications, as well as the manufacturing of HVAC components. 3. The 5052 Aluminum Alloy is recognized for its remarkable strength, excellent corrosion resistance, and good formability. It is ideally suited for marine and automotive applications, including the production of fuel tanks and body panels. 4. The versatile and widely utilized 6061 Aluminum Alloy offers a favorable balance of strength, formability, and corrosion resistance. It finds wide-ranging use in structural components, automotive parts, and aerospace components. 5. The 7075 Aluminum Alloy is characterized by its high strength-to-weight ratio and exceptional fatigue resistance. It is predominantly employed in critical applications where strength and durability are paramount, such as the aerospace industry. These examples represent merely a selection of the diverse aluminum alloys employed in coil production. Each alloy possesses distinct properties tailored to specific applications, and manufacturers make their selection based on the desired characteristics of the final product.

- Q: Can aluminum coils be used in architectural applications?

- Yes, aluminum coils can be used in architectural applications. Aluminum is a versatile and durable material that is commonly used in the construction industry for its lightweight nature, corrosion resistance, and ease of fabrication. Aluminum coils are often utilized in architectural applications such as roofing, cladding, and facades due to their ability to be easily formed into various shapes and sizes. Additionally, aluminum coils can be coated with different finishes to enhance their aesthetics and provide additional protection against weathering and fading. Overall, aluminum coils are a popular choice for architectural applications as they offer a combination of functionality, aesthetics, and longevity.

- Q: This question asks for the current prices of aluminum coil in various regions around the world.

- <p>The price of aluminum coil can vary significantly based on factors such as market demand, supply, transportation costs, and regional economic conditions. Prices are typically quoted per metric ton and are influenced by the London Metal Exchange (LME) and regional metal exchanges. For the most accurate and up-to-date prices, it's best to consult with local metal suppliers or check online commodity trading platforms. Prices can change daily, so real-time data is essential for making informed decisions.</p>

- Q: What are the legal frameworks or regulations that control the manufacturing and distribution of aluminum coil?

- <p>Yes, there are regulations and laws governing the production and sale of aluminum coil. These often include environmental protection laws that regulate emissions and waste disposal, safety standards for manufacturing processes, and quality control regulations to ensure the product meets certain specifications. Additionally, trade laws and tariffs may affect the sale of aluminum coil, especially when it crosses international borders. Compliance with these regulations is crucial to avoid penalties and maintain a competitive edge in the market.</p>

- Q: aluminium plate - 1800mm x 950mm x 1.5mmprocesses - i) sandblasting ii) polyethylene coating iii) matt blastingWhy does aluminium plate warp after the first process?How to prevent warping? Other than increasing material thickness (weight issue)

- It warps because the blasting is relieving stresses in the material. If you stress relieve the material first, it's a heat treating process, then flatten it with a press brake and it will stay flat during sand blast. You might try using aluminum tooling plate, and a chemical etch if your coating needs it to adhere.

- Q: What are the different alloy compositions used in aluminum coils?

- Aluminum coils utilize various alloy compositions, each with distinct properties and applications. Let's explore some of the commonly employed compositions: 1. The 1000 series alloys are nearly pure aluminum, boasting exceptional ductility and corrosion resistance, with a minimum aluminum content of 99%. These alloys find utility in scenarios demanding formability and efficient electrical conductivity, such as electrical wiring and packaging. 2. Manganese is present in small quantities within the 3000 series alloys, rendering them sturdier and more corrosion-resistant than their 1000 series counterparts. Cooking utensils, chemical equipment, and decorative trim are among the applications where these alloys are frequently employed. 3. Magnesium serves as the primary alloying element in the 5000 series alloys, significantly enhancing their strength and hardness. Renowned for their impressive resistance to corrosion, these alloys are commonly utilized in marine environments, as well as the automotive and aerospace industries. 4. The 6000 series alloys are combined with magnesium and silicon, leading to improved strength, heat treatability, and weldability. Architectural and structural components, transportation, and electrical conductors often rely on these alloys. 5. Zinc is the primary alloying element in the 7000 series alloys, providing them with remarkable strength and toughness. These alloys are frequently employed in high-stress environments, including aircraft structural components and sporting equipment. It is crucial to acknowledge that numerous alloy compositions are employed in aluminum coils, each tailored to specific requirements and applications. The choice of alloy composition hinges on factors such as desired strength, corrosion resistance, formability, and cost considerations.

- Q: Are aluminum coils suitable for electrical conductivity applications?

- Aluminum coils are well-suited for applications that require electrical conductivity. Aluminum is renowned for its exceptional electrical conductivity, ranking second only to copper among commonly used metals. With about 61% of the conductivity of copper, it is a dependable choice for various electrical purposes. Aluminum coils find extensive use in power transmission, transformers, and electrical motors due to their efficient electrical conduction capabilities. Moreover, their lightweight nature makes handling and installation in electrical systems easier. However, it is important to acknowledge that aluminum has higher resistance than copper, necessitating larger aluminum conductors to achieve the same electrical performance. All in all, aluminum coils serve as a fitting choice for applications that require electrical conductivity.

- Q: How are aluminum coils used in the production of battery enclosures?

- Due to their exceptional properties, aluminum coils find wide application in the manufacturing of battery enclosures. Firstly, aluminum, being a lightweight material, is perfect for creating battery enclosures that are lightweight themselves, a crucial feature for portable devices and electric vehicles where weight reduction is of utmost importance. Moreover, aluminum coils can be easily shaped and sized to accommodate specific battery designs, giving manufacturers the ability to customize the enclosures. This flexibility in shaping also aids in optimizing space utilization and enhancing the overall efficiency of the battery system. Furthermore, aluminum exhibits high resistance to corrosion, a vital characteristic for battery enclosures that are frequently exposed to harsh chemicals and environments. This corrosion resistance ensures the longevity and dependability of the enclosure, safeguarding the battery cells from harm and guaranteeing safe operation. Additionally, aluminum possesses excellent thermal conductivity, enabling efficient dissipation of heat generated during battery charging and discharging. This is crucial in preventing overheating and maintaining the optimal temperature range for optimal battery performance. In conclusion, aluminum coils play a pivotal role in the production of battery enclosures by providing lightweight, customizable, corrosion-resistant, and thermally conductive properties. These properties contribute to the overall efficiency, safety, and durability of battery systems employed in a wide range of applications, including consumer electronics, electric vehicles, and renewable energy storage.

Send your message to us

Customized Color Aluminum Coated Coils for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords