Aluminum Color Coils with Different Thickness and Width

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coils with Different Thickness and Width

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Aluminum Coils with Different Thickness and Width

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Coils with Different Thickness and Width

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

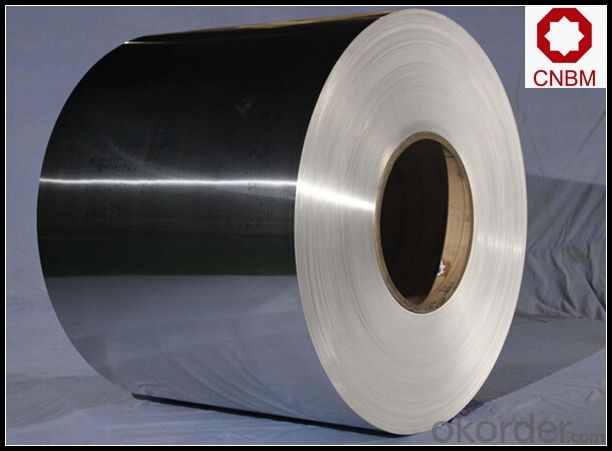

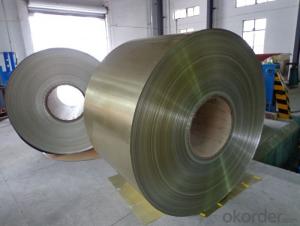

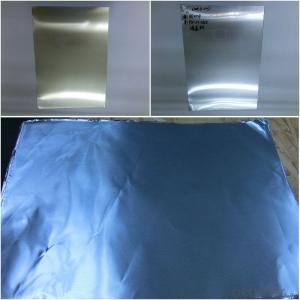

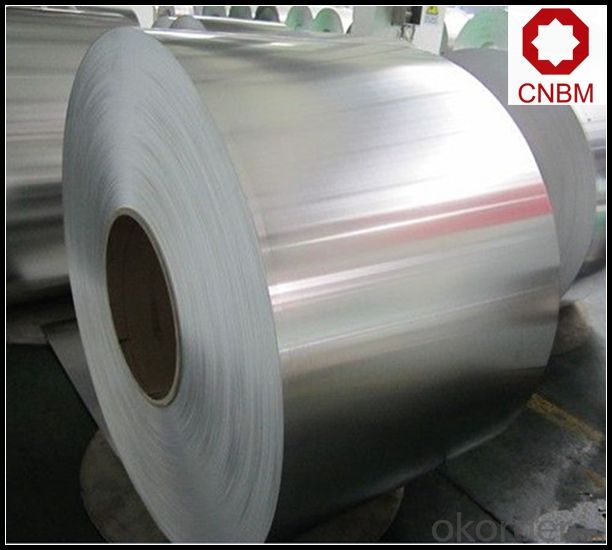

5. Image of Aluminum Coils with Different Thickness and Width

6. Package and shipping of Aluminum Coils with Different Thickness and Width

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the width tolerances for aluminum coils?

- The width tolerances for aluminum coils vary depending on the specific grade and type of coil. However, typical width tolerances for aluminum coils range from +/- 0.005 to 0.020 inches.

- Q: What are the different thickness options for aluminum coils?

- Various industrial and commercial applications can be catered to with a wide range of thickness options for aluminum coils. The thickness of these coils is typically measured in gauge or millimeters (mm). Aluminum coils are available in different thickness options: 1. Thin Gauge: Coils with a thin gauge usually have a thickness ranging from 0.15 mm to 0.4 mm. These coils are commonly utilized in applications that necessitate lightweight and flexible materials, such as packaging, electrical wiring, and insulation. 2. Standard Gauge: Coils with a standard gauge have thicknesses ranging from 0.4 mm to 2.5 mm. They find widespread use in industries like construction, automotive, and aerospace for applications like roofing, cladding, heat exchangers, and structural components. 3. Thick Gauge: Coils with a thick gauge typically have a thickness above 2.5 mm. These coils are predominantly employed in heavy-duty applications that require high strength, durability, and load-bearing capacity. Examples include shipbuilding, industrial machinery, and large-scale structural frameworks. It is important to note that the availability of specific thickness options may vary depending on the manufacturer and the intended application. Additionally, custom thicknesses can be manufactured to meet specific project requirements.

- Q: Can aluminum coils be used for food processing equipment?

- Yes, aluminum coils can be used for food processing equipment. Aluminum is a popular material choice for its excellent heat transfer properties, corrosion resistance, and lightweight nature. It is commonly used in the construction of food processing equipment such as heat exchangers, evaporators, and condensers.

- Q: Can aluminum coils be bent or shaped?

- Indeed, aluminum coils possess the capability of being bent and shaped. Aluminum, as a remarkably malleable and ductile metal, can undergo manipulation and take on diverse forms effortlessly, without experiencing any fractures or cracks. The pliability of aluminum grants it the capacity to be bent, rolled, or molded into coils, solidifying its prominence in a wide array of applications, including the production of air conditioning units, automotive components, and packaging materials. The flexibility and shape-altering potential of aluminum coils render them exceptionally versatile and adaptable to meet specific design specifications, facilitating efficient and precise customization across a multitude of industries.

- Q: Can aluminum coils be used in the manufacturing of cans and containers?

- Yes, aluminum coils can be used in the manufacturing of cans and containers. Aluminum is a lightweight and durable material that is widely used in the packaging industry. Aluminum coils are typically rolled into thin sheets, which are then cut and formed into the desired shape for cans and containers. These coils provide a cost-effective and efficient way to produce large quantities of cans and containers, as they can be easily processed and shaped. Additionally, aluminum is a highly recyclable material, making it environmentally friendly and sustainable for the packaging industry. Overall, aluminum coils are commonly used in the manufacturing of cans and containers due to their versatility, durability, and recyclability.

- Q: i have a project that requires me to know how safeway aluminum foil is made. i researched it on the internet, and also called safeway for it. they never gave me an answer. same for the diamond aluminum foil.please help!!!!i just need to know where they make it, how thick it is, and/or information about the ingots (such as size)and also temp. of heating room

- they start with a huge block of aluminum, then run that forth and back between giant steel cylinders until it is a relatively thin and very long sheet of metal. Then this sheet is run trough a series of these drums until it is foil of the required thickness. Then they cut the wide foil in strips of the right width and package it for sale. Hope this helps.

- Q: What are the different alloy compositions used in aluminum coils?

- There are several different alloy compositions used in aluminum coils, including 1xxx series (pure aluminum), 3xxx series (aluminum-manganese), 5xxx series (aluminum-magnesium), and 8xxx series (aluminum-lithium). Each alloy composition offers unique properties and characteristics, making them suitable for various applications in industries such as automotive, construction, and aerospace.

- Q: Is it possible to customize the dimensions of aluminum coils?

- Yes, it is possible to customize the dimensions of aluminum coils. Aluminum coils can be cut and shaped according to specific requirements and dimensions based on the application they are intended for. Customization allows for flexibility in design and ensures the aluminum coils meet the specific needs of the project.

- Q: How are aluminum coils used in the production of food processing equipment?

- Aluminum coils are commonly used in the production of food processing equipment due to their excellent thermal conductivity, corrosion resistance, and lightweight nature. These coils are often formed into various shapes and sizes to create components like heat exchangers, evaporators, and condensers that help regulate temperature during food processing. Additionally, aluminum coils can be easily cleaned and sanitized, making them ideal for use in the food industry where hygiene is crucial.

- Q: How do aluminum coils contribute to energy-efficient lighting systems?

- Aluminum coils are essential components in energy-efficient lighting systems due to their unique properties and functionalities. Firstly, aluminum is an excellent conductor of electricity, allowing for efficient energy flow within the lighting system. This property ensures that minimal energy is lost during transmission, maximizing the overall energy efficiency of the system. Moreover, aluminum coils are lightweight and durable, making them ideal for use in lighting systems. The lightweight nature of aluminum allows for easier installation and handling, reducing the overall energy required during the manufacturing and installation processes. Additionally, aluminum's durability ensures that the coils can withstand the rigors of daily use without compromising performance, further contributing to the longevity and efficiency of the lighting system. Furthermore, aluminum has excellent thermal conductivity, allowing for efficient heat dissipation. Heat management is crucial in lighting systems as excessive heat can reduce the lifespan and efficiency of the bulbs. By using aluminum coils, the heat generated by the lighting system can be effectively dispersed, minimizing the risk of overheating and ensuring optimal performance. In summary, aluminum coils contribute to energy-efficient lighting systems by providing efficient electrical conductivity, lightweight and durable construction, and effective heat dissipation. These properties help to minimize energy loss, reduce manufacturing and installation energy requirements, and enhance the overall efficiency and longevity of the lighting system.

Send your message to us

Aluminum Color Coils with Different Thickness and Width

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords