Customized Embossed Aluminum Coil for Decoration and Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium Strips Use for Decoration and Building

l Product Specification

Product | Aluminium Strip | ||

Alloy | 1100, 1145, 1050, 1060, 1070, 3003, 3013, 3005, 3A21, 4343, 4045, 5052, 5082, 5083, 5086, 6061, 8011etc. | Temper | H12. H14. H16. H18. H22. H24. H26. H32. H34. H36. H38. O etc. |

Thickness | 0.06mm-6.0mm | Width | 5mm-900mm |

Coil Weight | At clients' request | ||

Package | Eye to sky and eye to wall both available | ||

Inner core Diameter | 76mm, 505mm, paper core or steel coil is availbale, also we can make no core inside | ||

Applications | Gutter, constructions, decorations, air conditioning and radiators etc. | ||

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirement

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

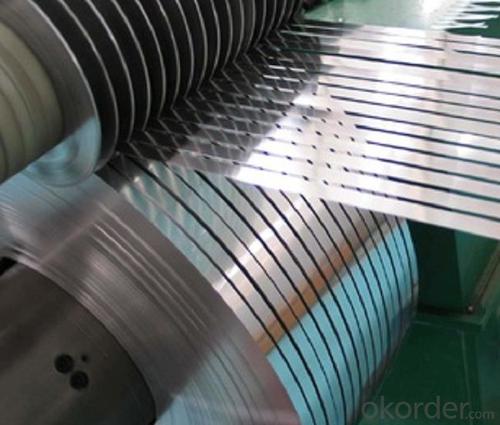

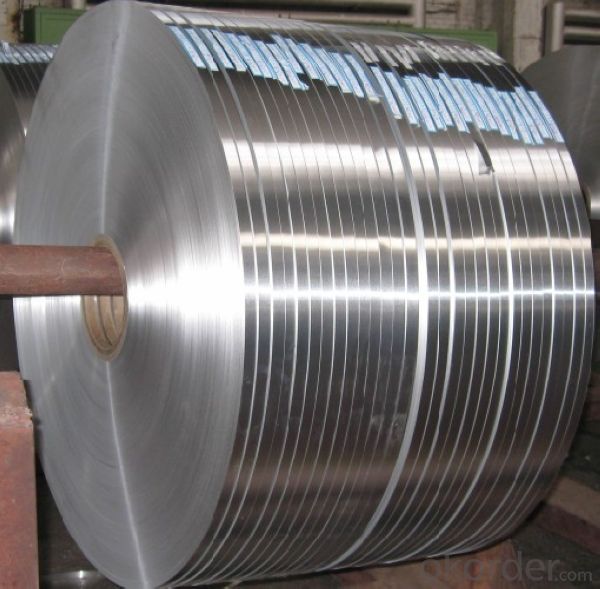

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What are the production processes of aluminum coil and what are the functions of various industrial furnaces in the production of aluminum? The more detailed, the better. Thank you! Points!

- There are aluminum annealing furnace, aluminum alloy quenching furnace, aging furnace and smelting furnace.

- Q: How to calculate the wall thickness with the gross weight of aluminum coil known?

- Gross weight*density=volume volume÷(aluminum sheet *width)=thickness

- Q: my text says aluminium does not corrode much as a passive aluminium oxide layer is formed on it.Well other metals such as sodium adn potassium also form oxides. Why dont their oxides prevent further oxidation ?

- sodium oxide and potassium oxide are water soluble aluminium oxide is not water soluble. the layer formed of oxide on the aluminium surface is coherent and adherent with no pores and stuck to the metal surface. the layer is also passive to most acids and alkalies except HCl and anti passive ions if present. sodium oxide and potassium oxide dissolve in any aqueous medium forming the corresponding alkalies NaOH and KOH leaving the fresh metal surface exposed to more corrosion. also the reaction of Na and K with aqueous media like water and acids is quite vigorous and fast unlike aluminium which is mu less reactive

- Q: What are the different coil cutting options for aluminum coils?

- Aluminum coils have various options for cutting, depending on the project's specific needs. Some common choices include: 1. Shearing involves using a shear blade to cut straight through aluminum coils. This method is ideal for thinner gauges of aluminum. 2. Slitting cuts aluminum coils into narrower strips by passing them through rotating circular blades. It is commonly used in industries like roofing, automotive, and packaging. 3. Cut-to-Length is a method where aluminum coils are cut into individual sheets of desired lengths. The process involves uncoiling, leveling, and cutting with a flying or stationary shear. This option is suitable for applications requiring precise sheet lengths. 4. Laser Cutting utilizes a high-powered laser beam to melt and vaporize the metal, resulting in clean and precise cuts. It is often used in aerospace and electronics industries for cutting complex shapes and patterns. 5. Waterjet Cutting involves using a high-pressure jet of water mixed with an abrasive material to cut through the coils. It is particularly effective for thicker gauges of aluminum without heat-affected zones or material distortion. These options provide different ways to cut aluminum coils. The choice of method depends on factors such as the desired end product, required precision, material thickness, and production volume. Considering the project's specific requirements is crucial in selecting the most appropriate cutting option.

- Q: I live in blue ridge ga and have about 2,000 aluminum cans and would like to know how much I can get for them.

- The price for scrap aluminum cans varies litteraly every day. Within the last year, it has been between about 28 cents and 50 cents a pound. The last price I saw for clean, flattened cans delivered to the dealer was about 42 cents. As I said, it could be a bit higher or lower than that now. There are about 30-32 cans per pound of aluminum, so your 2,000 cans probably weigh around 64 pounds and could be worth about $27, assuming there has been no big change in the price recently. But that's a delivered price. If you have to drive 10 miles each way and your truck gets 20 mpg, you will be paying for a gallon of gas. If it is 30 miles each way (60 miles total), you are looking at 3 gallons of gas, which is probably about $8, leaving you a profit of around $19, or maybe a little less. That's with some optimistic assumptions, and it doesn't include the cost of big plastic bags to carry the cans. Not very encouraging, is it? Recycling makes sense for a big city or a recycling center, where they can get thousands of cans a day. But it is hard for an individual to make any money at it. i know this is not what you wanted to hear, but I hope it is helpful anyway.

- Q: Are aluminum coils more expensive than other coil materials?

- It depends on the specific material being compared. Generally, aluminum coils tend to be more expensive than some other coil materials, such as copper or steel. However, the cost can vary depending on factors like the coil size, thickness, and supplier.

- Q: How are aluminum coils used in the production of food processing equipment?

- Aluminum coils are widely used in the production of food processing equipment due to their desirable characteristics and benefits. These coils are typically made from high-quality aluminum alloy, which offers excellent heat conductivity, corrosion resistance, and durability. One primary application of aluminum coils in the food processing industry is in the construction of heat exchangers. These heat exchangers are essential components of various food processing equipment, such as ovens, fryers, and refrigeration systems. The aluminum coils within the heat exchangers facilitate the transfer of heat between different mediums, ensuring efficient and precise temperature control during food processing. Another important use of aluminum coils is in the manufacturing of evaporator coils. These coils are integral to refrigeration systems used in commercial food processing. The evaporator coils, made from aluminum, aid in the cooling process by absorbing heat from the surrounding environment and allowing refrigerants to evaporate, thereby maintaining low temperatures within the equipment. Additionally, aluminum coils find application in the construction of food storage and transportation equipment, such as refrigerated trucks and containers. Aluminum's lightweight nature contributes to fuel efficiency and enables easier transportation of food products while maintaining their quality and freshness. Furthermore, aluminum coils are valued for their hygienic properties and ease of cleaning, making them ideal for food processing equipment. Aluminum surfaces can be easily sanitized, ensuring a high level of cleanliness and preventing contamination during food production. Overall, aluminum coils play a crucial role in the production of food processing equipment by providing excellent heat transfer, corrosion resistance, durability, and hygienic qualities. Their usage helps ensure efficient food processing operations, optimal temperature control, and the maintenance of food quality and safety standards.

- Q: Is it possible to utilize aluminum coils in the packaging of food products?

- <p>Yes, aluminum coils can be used for food packaging. They are commonly used in the production of aluminum foil, which is a popular material for food packaging due to its properties such as light weight, barrier to light and oxygen, and recyclability. Aluminum foil is used to wrap food, line baking sheets, and create containers, providing a protective barrier that helps to preserve freshness and extend shelf life. However, it's important to ensure that the aluminum used meets food-grade standards to avoid any health risks.</p>

- Q: What is the role of aluminum coils in the construction of railways?

- Aluminum coils are used in the construction of railways for various purposes, primarily for the manufacturing of overhead lines and electrical conductors. Due to their high conductivity, lightweight nature, and corrosion resistance, aluminum coils are ideal for transmitting electrical power and ensuring efficient and reliable railway operations. These coils are also utilized in the production of railway carriages and components, providing strength and durability while reducing overall weight, which ultimately improves fuel efficiency and lowers operating costs. Overall, aluminum coils play a crucial role in enhancing the performance, safety, and sustainability of railway systems.

- Q: What are some common defects in aluminum coils?

- Aluminum coils may have several common defects, which are as follows: 1. Surface imperfections: Scratches, pits, dents, or waviness can be observed on the coil's surface. These defects may arise during manufacturing or due to mishandling during transportation or storage. 2. Edge irregularities: Coil edges might exhibit burrs or unevenness. Improper slitting or cutting processes can lead to such defects. 3. Coating abnormalities: When an aluminum coil is coated with a protective or decorative layer, issues like peeling, cracking, or uneven coating thickness may occur. These problems can be attributed to incorrect application or inadequate curing of the coating. 4. Corrosion: Although aluminum is generally resistant to corrosion, it can still be susceptible to corrosion in specific environments. Corrosion can manifest as pitting, staining, or the presence of white powdery deposits on the coil's surface. 5. Alloy flaws: In certain instances, the aluminum alloy used in the coil might contain defects such as inclusions, impurities, or an improper composition. These flaws can have an adverse impact on the coil's mechanical properties and overall performance. 6. Shape irregularities: Aluminum coils are expected to possess a consistent and uniform shape. However, defects such as coil set (where the coil retains a curvature after unwinding) or camber (where the coil exhibits a slight curvature across its width) can occur. These defects are usually caused by incorrect tension or cooling during the manufacturing process. 7. Welding defects: If the aluminum coil is produced by welding multiple sheets or strips of aluminum together, defects in the welds can occur. These defects include incomplete welds, cracks, or porosity, which can weaken the coil and compromise its structural integrity.

Send your message to us

Customized Embossed Aluminum Coil for Decoration and Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords