Us Aluminum Coil Company Capf3137bcaa Aluminum Coil 3003 H14 for Air Conditioning Condensers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

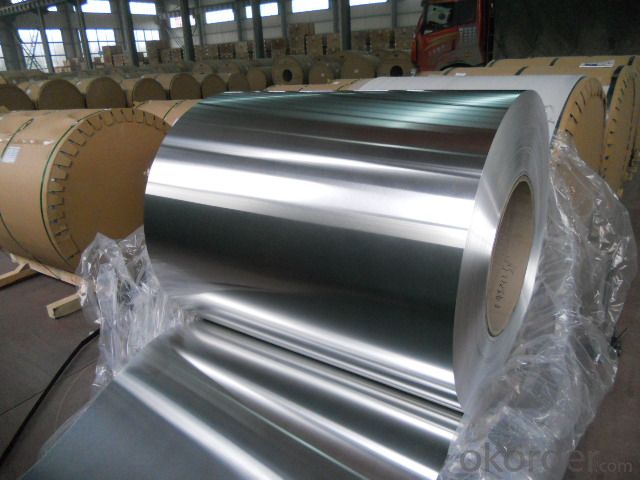

Aluminum Coil 3003 H14 for Air Conditioning Condensers

l Product Introduction

Aluminium Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification

Grade: 3000 series

Alloy or not : Alloy

Thickness :0.15-3.0mm

Width:7.5-2000mm

Place of origin: Jiangsu province ,China mainland

Certificate: ISO9001:2008 ISO14001:2004 ,MSDS ,SGS ,Mill test ,GB/T3880-2006

Typical Chemistry:

Cu: 0.20

Si: 0.60

Fe: 0.70

Mn: 1.0/1.5

Zn: 0.10

Aluminum: Balance

Characteristics: The 3003 alloy is non-heat-treatable, its corrosion resistance and formability are excellent, but its anodizing characteristics are rated as fair.

Mechanical Properties:

Tensile Strength: 110-205

Yield Srength: 40-190

Elongation: 30-4

Brinell Hardness: 28-47

Typical Application:

3003 is often used in general sheet metal work, stamped, spun and drawn parts, cabinets, mail boxes, food and chemical storage and handling. If part is to be anodized consider 5005, if higher strength is desired consider 5052.

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: aluminum welding

- They make aluminum welding sticks with flux that work with DC welders.

- Q: What precautions should be taken to ensure the safe and efficient transportation of aluminum coils?

- <p>The best way to handle aluminum coil during transportation involves using proper lifting equipment, ensuring secure strapping, and maintaining a stable and dry environment. Use slings or lifting beams specifically designed for metal coils to prevent damage. Ensure the coil is strapped tightly to prevent shifting during transit. Keep the coils covered to protect from moisture and dirt. Always follow the manufacturer's guidelines for weight limits and handling procedures.</p>

- Q: What are aluminum coils used for and what are their applications?

- <p>Aluminum coils are versatile metal products that serve various purposes. They are primarily used in construction, manufacturing, and packaging industries. Some common applications include roofing and siding materials, heat exchangers, food and beverage cans, automotive parts, and electrical components. Aluminum coils are valued for their lightweight, corrosion resistance, and high thermal and electrical conductivity, making them ideal for a wide range of applications where durability and efficiency are required.</p>

- Q: Can aluminum coils be used in HVAC heat exchangers?

- Yes, aluminum coils can be used in HVAC heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. Aluminum coils are often used in air conditioning systems and heat pumps, where they transfer heat efficiently between the refrigerant and the surrounding air. Additionally, aluminum coils are easier to shape and form, allowing for more intricate designs and better heat transfer performance. Overall, aluminum coils are a reliable and effective choice for HVAC heat exchangers.

- Q: What are the advantages of using aluminum coils in various industries?

- Using aluminum coils in various industries offers several advantages. Firstly, aluminum is lightweight, making it easy to handle and transport. This is especially beneficial in industries like aerospace and automotive, where reducing weight improves fuel efficiency and overall performance. Secondly, aluminum has excellent corrosion resistance. It forms a natural oxide layer that protects it from rust and other forms of corrosion, making it durable and long-lasting. This makes aluminum coils suitable for industries like construction, marine, and HVAC, where exposure to moisture and harsh environments is common. In addition, aluminum has high thermal conductivity, efficiently transferring heat. This makes it ideal for heat exchangers, refrigeration systems, and other applications requiring effective heat dissipation. Moreover, aluminum is highly recyclable, requiring less energy than producing primary aluminum. Using aluminum coils promotes sustainability and reduces environmental impact, making it attractive for companies aiming to adopt eco-friendly practices. Furthermore, aluminum coils can be easily formed and shaped into various sizes and dimensions, allowing for flexible design options and customization. This versatility makes it suitable for a wide range of applications in industries like packaging, electrical, and telecommunications. Lastly, aluminum coils offer cost advantages in terms of initial investment and maintenance. While the upfront cost may be higher than other materials, the long-term benefits of durability, low maintenance requirements, and energy efficiency make it a cost-effective choice. In conclusion, the advantages of using aluminum coils in various industries include lightweight nature, corrosion resistance, high thermal conductivity, recyclability, versatility, and cost-effectiveness. These qualities make aluminum coils a preferred material for many industrial applications, contributing to improved performance, durability, and sustainability.

- Q: My school has lunched catered in daily because it cuts down on staff in the kitchen. The food is delivered in individual aluminum containers for each student. In doing so, the school uses 99,000 aluminum trays in one school year, all of which get thrown away. I'm trying to find an alternative such as biodegradable food containers. Does anyone have any ideas? The container has to be able to withstand the heat of an oven.

- Why not keep using the aluminum? It's 100 percent recyclable! That's even better than having something in a landfull bio-degrading over 10 years!

- Q: What is the minimum width of aluminum coils?

- The minimum width of aluminum coils can vary depending on the specific requirements and manufacturing capabilities. However, in general, the minimum width of aluminum coils typically ranges from around 0.25 inches to 0.5 inches. It is important to note that specialized manufacturing processes may allow for even narrower widths, but these are less common and may come with additional costs or limitations. Additionally, the specific application and industry requirements will also play a role in determining the minimum width needed for aluminum coils.

- Q: Are aluminum coils suitable for HVAC ductwork?

- Yes, aluminum coils are suitable for HVAC ductwork. Aluminum is a lightweight, durable, and corrosion-resistant material, making it an ideal choice for HVAC ductwork. It offers excellent heat transfer properties and is commonly used in both residential and commercial HVAC systems.

- Q: How do aluminum coils contribute to energy-efficient insulation?

- Aluminum coils contribute to energy-efficient insulation by serving as a barrier that prevents the transfer of heat. Due to aluminum's excellent thermal conductivity, it efficiently conducts and dissipates heat, reducing energy loss and improving insulation performance. Additionally, aluminum coils can be used in the construction of air conditioning and refrigeration systems, where they enhance energy efficiency by enabling better heat transfer and reducing energy consumption.

- Q: Can aluminum coils be painted?

- Yes, aluminum coils can be painted. Painting aluminum coils can provide an added layer of protection against corrosion and enhance their aesthetic appearance. However, it is important to properly prepare the surface before painting to ensure good adhesion and durability. This typically involves cleaning the coils thoroughly, removing any existing paint or coatings, and applying a primer specifically designed for use on aluminum surfaces. Once the primer has dried, a suitable paint can be applied using a brush, roller, or spray. It is recommended to use a high-quality paint specifically formulated for use on metal surfaces to ensure long-lasting results. Additionally, it is important to follow the manufacturer's instructions and consider any environmental factors that may affect the painting process, such as temperature and humidity.

Send your message to us

Us Aluminum Coil Company Capf3137bcaa Aluminum Coil 3003 H14 for Air Conditioning Condensers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords