Customized Aluminum Sheets for Track Transportation for Sale Nz

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Introduction

Aluminum sheet is also known as Treadplate, Floor Plate, Chequer Plate, Checkered Plate, Chequered Floor Plate, Checker Plate and Check Plate. It is made of anti-corrosion aluminum alloy stock, rolled with special and beautiful embossing shape. It has the property of anti-sliding, anti-corrosion, easy cleaning and high mechanical strength.

l Specification

Material | 1,2,3,5,6,7,8 series |

Temper | O, F, H14, H34, H32, H112, T4, T6 |

Surface treatment | Mill Finish,Anodized,Eletropharesis,Powder Coated, Wooden Finish, Polish |

Colour | Silver,Black,Red,Blue,or as required |

Length | As required |

Shape | Plain,bossed,or as per the drawings and samples |

Fabrication | cutting,drilling,punching,bending,etc |

Tolerances | As per your requirements |

Payment terms | TT |

Price terms | FOB;CIF;CFR |

Delivery time | 15-20 days after order confirmation |

Certification | ISO 9001:2008; |

Application | Decorations,Fence,Building,Aviation industry,Mechancal equipment |

Capacity | 5000 tons per month |

Min order quantity | 5 Metric tons |

lPackaging & Delivery

Packaging detail: wooden cases that are suitable for long distance exporting

Delivery detail: 25-30 days after receiving L/C or payment in advance

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

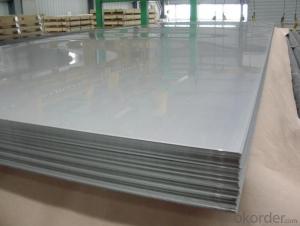

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email:service@okorder.com

- Q: How do you prevent distortion of aluminum sheets during welding?

- To prevent distortion during the welding of aluminum sheets, there are several important steps that can be taken: 1. It is crucial to properly prepare the joint by cleaning and beveling the edges of the aluminum sheets. This will ensure a better fit-up and reduce the likelihood of distortion. 2. The use of appropriate fixtures and clamps to hold the aluminum sheets in place during welding can help distribute the heat evenly and prevent movement or buckling. This will minimize the risk of distortion caused by thermal expansion. 3. Tack welding can be done at regular intervals along the joint before performing a full weld. This temporarily secures the sheets and allows for controlled cooling, reducing distortion. 4. Following a proper welding sequence is also beneficial. Starting from the center and gradually moving towards the edges, alternating between sides, helps balance the heat input and allows for cooling between welds, minimizing distortion. 5. Preheating the material before welding can help reduce the temperature gradient and minimize distortion for thicker aluminum sheets. Post-weld heat treatment can also be applied to relieve residual stresses and promote dimensional stability. 6. Employing appropriate welding techniques, such as lowering the heat input and using a slower travel speed, can help minimize distortion. Using a smaller weld bead size and avoiding excessive weaving also control the heat input and reduce distortion. 7. It is crucial to ensure that the welding parameters, such as voltage, current, and wire feed speed, are correctly set and maintained. Using the appropriate parameters for the specific aluminum alloy being welded will result in a more controlled heat input, reducing distortion. By implementing these preventive measures, the risk of distortion during aluminum sheet welding can be significantly reduced, leading to improved weld quality and dimensional stability.

- Q: I need to install hand rails around a hot tub and wonder if aluminum would work well.

- Aluminum is not a good choice, even if it's anodized, painted, or powder coated. Pool water is corrosive mostly due to the chloride from chlorination. Steel is slightly less prone to corrosion. Plastic or fiberglass is the best choice.

- Q: With a project I'm working on, I need to reinforce a small case made of aluminium. My options are to use regular old screws (probably steel) or Stainless Steel screws (much more costly). Just wondering what corrosion will be like? *It will never ever get wet,* so does that mean corrosion will not occur? (to a certain degree, obviously) And would corrosion, since its dry, still be affected by the type of metal used for the screws? The screws need to be strong, and they also need to be purchase-able at a regular hardware store, as I'm not going to go buying just screws on-line. Thanks for any info you can provide.

- You don't mention just what this project is, but 'regular' screws in the aluminum will not 'rust' - but they may cause galvanic action (a white powdery aluminum oxide may form over time.) Most hardware stores carry aluminum screws, why not just buy and use them if you are concerned? They are usually used for aluminum replacement windows and may be painted white. You can use sandpaper to remove the paint if you want the silver to show.

- Q: Are aluminum sheets suitable for architectural applications?

- Architectural applications can indeed benefit from the suitability of aluminum sheets. Aluminum, being a versatile material, offers numerous advantages for architectural projects. It possesses a lightweight quality while still being strong, making it easy to handle and install. Furthermore, its resistance to corrosion makes it ideal for outdoor applications that are exposed to the elements. The malleability of aluminum sheets allows them to be easily formed into different shapes and sizes, enabling architects to create innovative and creative designs. These sheets find their use in various architectural applications such as cladding, roofing, facades, as well as interior elements including ceilings, partitions, and decorative components. Moreover, architects have the freedom to choose from a wide range of finishes for aluminum sheets, including anodized, painted, or coated. These finishes not only enhance the aesthetics of the projects but also improve the material's durability and color retention, thereby ensuring long-term performance and minimal maintenance requirements. Beyond these advantages, aluminum is also a sustainable material. It is fully recyclable and has a lower carbon footprint compared to other metals. This aligns with the growing emphasis on environmentally-friendly construction practices in the architectural industry. In conclusion, due to their lightweight nature, strength, corrosion resistance, versatility, range of finishes, and sustainable attributes, aluminum sheets are highly suitable for architectural applications. Architects can confidently incorporate aluminum sheets into their designs, resulting in visually appealing and durable structures.

- Q: Aluminum knowledge. What is the model 3003 H24? What does H mean?

- According to the main alloy aluminum alloy elements can be divided into 2 * * * for Al Cu alloy aluminum (Al--Cu), 3 * * * aluminum manganese alloy aluminum (Al--Mn), 4 * * * series of aluminum silicon alloy aluminum (Al--Si), 5 * * * for aluminium magnesium alloy aluminum (Al--Mg). 6 * * * for Al Mg Si alloy aluminum (AL--Mg--Si), 7 * * * for aluminum and zinc alloy aluminum [AL--Zn--Mg-- (Cu)].

- Q: This question asks for the various dimensions in which aluminum sheets can be obtained.

- <p>Aluminum sheets are available in a variety of sizes depending on the manufacturer and the specific application. Common sizes include 12x12 inches, 24x24 inches, 4x8 feet, and 4x10 feet. Thickness can range from 0.010 inches (0.25 mm) for thin sheets to 0.5 inches (12.7 mm) for thicker plates. Custom sizes can also be ordered, and the availability of these sizes may vary by supplier. It's important to check with the specific supplier for the exact sizes they offer, as options can differ.</p>

- Q: Can aluminum sheets be used for signage?

- Yes, aluminum sheets can be used for signage. Aluminum is a versatile material that is durable, lightweight, and weather-resistant, making it suitable for outdoor and indoor signage applications. It can be easily customized, cut, and shaped to create various types of signage, including signs for businesses, roadways, and informational displays.

- Q: How do you form curves or shapes in aluminum sheets?

- There are several methods to form curves or shapes in aluminum sheets. One common technique is called bending, where the sheet is clamped and then gradually bent using a mechanical press brake or a hammer. Another method is called roll forming, which involves passing the aluminum sheet through a series of rollers to achieve the desired shape. Additionally, aluminum sheets can be molded or pressed into curves or shapes using specialized tools or dies.

- Q: Can the aluminum sheets be used for manufacturing aircraft parts?

- Yes, aluminum sheets can be used for manufacturing aircraft parts. Aluminum is a lightweight and durable material that is commonly used in the aerospace industry. It possesses excellent strength-to-weight ratio, corrosion resistance, and good formability, making it suitable for various aircraft applications. Aluminum sheets can be easily fabricated into complex shapes and are used to manufacture components such as wings, fuselages, panels, and structural supports in aircraft. Additionally, aluminum's high conductivity allows for efficient heat dissipation in critical areas of the aircraft. Overall, aluminum sheets are a preferred choice for manufacturing aircraft parts due to their favorable properties and reliability in the aerospace industry.

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Indeed, the utilization of aluminum sheets is viable for the production of decorative trim. Being a versatile substance, aluminum is renowned for its lightweight nature, durability, and exceptional resistance to corrosion. It bestows the convenience of effortless shaping and molding into diverse decorative configurations and motifs. Furthermore, aluminum's aesthetic allure can be accentuated by applying coatings or paints of assorted hues. Consequently, aluminum sheets emerge as a highly favored option for fabricating decorative trim across a multitude of sectors, encompassing architecture, automotive, and interior design.

Send your message to us

Customized Aluminum Sheets for Track Transportation for Sale Nz

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords