Order Custom Aluminum Sheets for Track Transportation Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Customized Aluminum Sheet & Strip for Track Transportation Use

l Product Introduction

The Aluminum Strip is mainly used for refrigerator, cable ,capacitor shell material, steal-protection cover, cable sheathing, composite pipe and tube, water pipe etc. It has the property of deep drawing, high thickness accuracy, and low earring rate, etc.

l Product Details

1. Specification

| Alloy | Temper | Gauge(mm) | ||

5000 series

| H32/H34/H116/HH321/H113 O/T4/T6/T651 | Thickness | Width | Length |

| 4-12 | 1000-2600 | 1000-16500 | ||

2. Production Feature

Wide,produced by widest 1+4 hot rolling line in China

Long, performance sustainable even after forming

Rust & erosion resistant

Well shaped

Good surface

l Packaging & Delivery

Packaging detail: Covering with brown paper and plastic bag then packed with wooden plywood then directly loading into container for transshipment. For the thickness which is more than 1.50mm, one paper interleave into two sheets.

Delivery detail: within 30days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium Strip has always been one of the most popular products in CNBM. With advanced technic skills and equipment, CNBM has produced high quality aluminium strips that meet international standard.

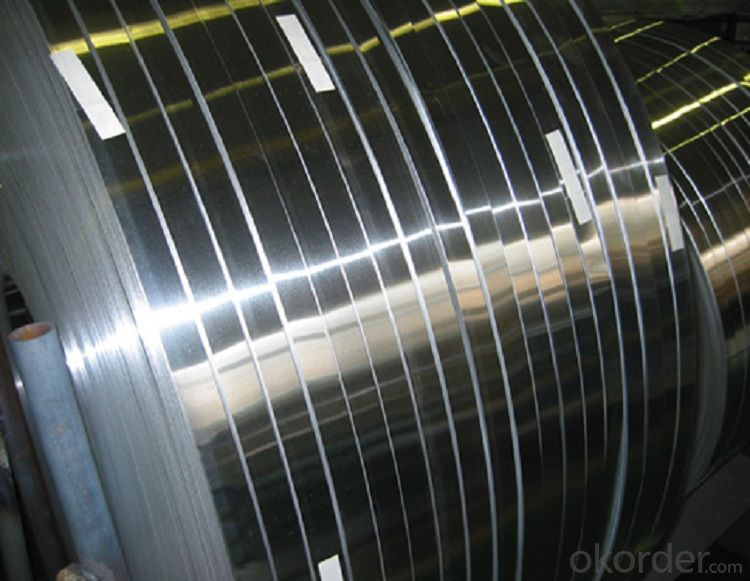

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: How does the surface finish affect the optical properties of aluminum sheet?

- The surface finish of aluminum sheet can significantly impact its optical properties. A smooth surface finish on aluminum sheet results in better light reflection and less scattering, leading to higher reflectivity. This means that more light is reflected off the surface, making the aluminum sheet appear brighter and more reflective. On the other hand, a rough or textured surface finish on aluminum sheet can cause light to scatter in different directions, reducing reflectivity. This can result in a duller and less reflective appearance. Additionally, the surface finish can affect the appearance of any coatings or films applied to the aluminum sheet. A smooth surface finish allows for better adhesion and uniformity of coatings, enhancing their optical properties. In summary, a smooth surface finish on aluminum sheet enhances its optical properties by increasing reflectivity and reducing scattering, resulting in a brighter and more reflective appearance.

- Q: Can I bake falafel patties in the oven using an aluminum foil on top of the pan I am using to put in the oven? Will the aluminum foil catch fire in the oven? Also, if I put the aluminum foil I wouldn't have to grease up the foil with oil...the patties just wont stick to aluminum foil right?

- Aluminum foil is just the metal called aluminum which has been pressed into a very thin sheet (foil), and metals won't melt or catch fire here and there till they get extremely hot (in huge furnaces). A home oven is waaay too cool for that. As for sticking, that depends on whether the foil is touching your patties and how much, as well as which ingredients you used in the patties since some will carmelize or dry out onto the foil but only where they contacted. You can always tent or make a dome with the foil so it doesn't touch any of the food though if you're concerned. Not sure why you'd be covering falafels though, since that will steam them (at least partly) not bake, them and therefore not create a crispy exterior.

- Q: where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- For okorder /

- Q: Are aluminum sheets easy to clean and maintain?

- Yes, aluminum sheets are generally easy to clean and maintain. They can be easily wiped clean with a damp cloth or sponge, and occasional cleaning with mild soap and water is usually sufficient. Additionally, aluminum is resistant to rust and corrosion, making it relatively low maintenance in comparison to other materials.

- Q: How does the surface roughness affect the adhesion of coatings on aluminum sheet?

- The adhesion of coatings on aluminum sheet is greatly influenced by the surface roughness. How rough the sheet's surface is directly impacts the mechanical interlocking between the coating and the substrate, which is vital for strong adhesion. When the aluminum sheet's surface is smooth, the contact area between the coating and the substrate is limited, resulting in weak adhesion. Conversely, a rough surface provides more contact points, enhancing the interlocking between the coating and the aluminum sheet, resulting in improved adhesion strength. Moreover, a rough surface facilitates better wetting of the coating material on the aluminum sheet. This means that the coating material can easily spread across the surface, filling any gaps or crevices and creating a more uniform and continuous coating. This improved wetting contributes to enhanced adhesion. Furthermore, a rough surface can also increase the overall surface area of the aluminum sheet. A larger surface area allows for more available space for the coating material to adhere to, thus increasing the adhesion strength. It is important to note that there is an optimal level of roughness required to achieve the best adhesion. Excessive roughness may result in incomplete coverage of the coating material or the formation of voids, reducing adhesion. Therefore, finding the right balance of roughness is essential to ensure optimal adhesion of coatings on aluminum sheet.

- Q: Can 101 aluminum sheets be used in architectural cladding?

- Certainly, architectural cladding can indeed utilize 101 aluminum sheets. The lightweight nature, durability, and resistance to corrosion make aluminum a favored option for architectural cladding. Specifically, grade 101 aluminum sheets find widespread use in architectural applications due to their impressive formability and easy workability. These sheets can be effortlessly cut, shaped, and joined to fashion tailor-made cladding solutions. Moreover, aluminum offers the possibility of being coated or anodized, allowing for enhanced aesthetics and added weather protection. Consequently, it is evident that 101 aluminum sheets prove suitable for various architectural cladding projects.

- Q: Why does the glue of the aluminium curtain wall glue bubble? At the same time, do not bubble on the side glass, what is the reason?

- Brothers, there are several kinds of bubble gum, first to check is not part of the foam glue strip plug is not good, should be smooth, playing in a plastic bubble, not to leave the air, also can't have water, air water will bubble. In addition, glue when the temperature is very important no, when hot hit. Glue master experience play a decisive role, there is a great work in absolute don't let coolie, evenness and speed are very important.

- Q: How many square meters does the aluminum plate engrave?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet. If you have any questions, please ask, thank you.

- Q: Can aluminum sheets be etched or engraved?

- Indeed, it is possible to etch or engrave aluminum sheets. The process entails removing a portion of the material from the surface by utilizing acid or a laser with substantial power. This technique allows for the creation of detailed designs, patterns, or even textual elements on the aluminum sheet. The applications for etching or engraving are diverse, including signage, decorative items, and industrial components. To achieve the desired appearance, color or other finishes can be added to further enhance the resulting design on the aluminum sheet.

- Q: This question asks about the various types of adhesives that can be used to bond aluminum sheets together.

- <p>There are several types of adhesives suitable for bonding aluminum sheets together, including epoxy adhesives, which offer strong bonding and resistance to heat and chemicals; acrylic adhesives, known for their flexibility and resistance to UV light; cyanoacrylate adhesives, or super glues, which provide fast bonding but may not be as strong for heavy-duty applications; polyurethane adhesives, which are durable and flexible; and silicone adhesives, which are excellent for high-temperature applications and provide water resistance. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, temperature resistance, and curing time.</p>

Send your message to us

Order Custom Aluminum Sheets for Track Transportation Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords