Customizable Aluminum Sheets in Minnesota for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

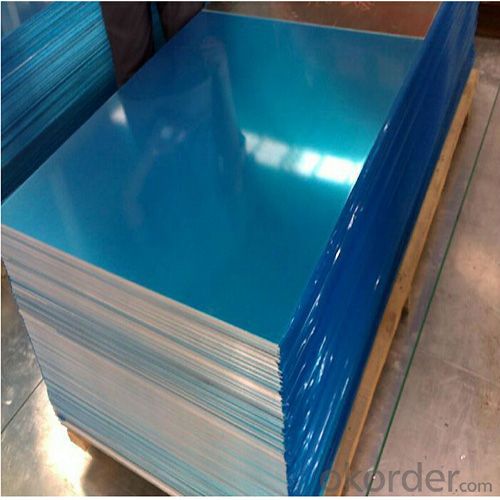

1.Structure of Customizable Aluminium Sheet Plate for Construction Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Customizable Aluminium Sheet Plate for Construction :

Low density, light in weight

Anti-corrosion

Strong

Malleable

Naturally good looking

Recyclable

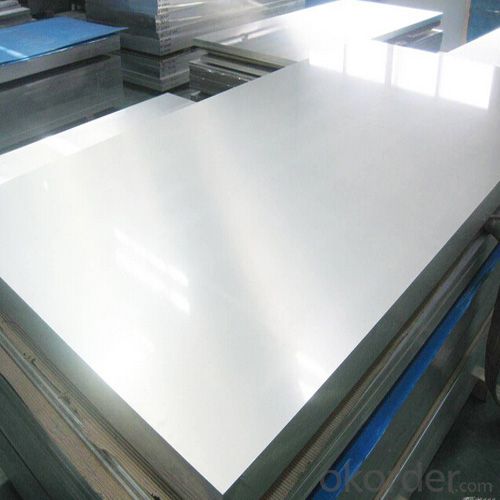

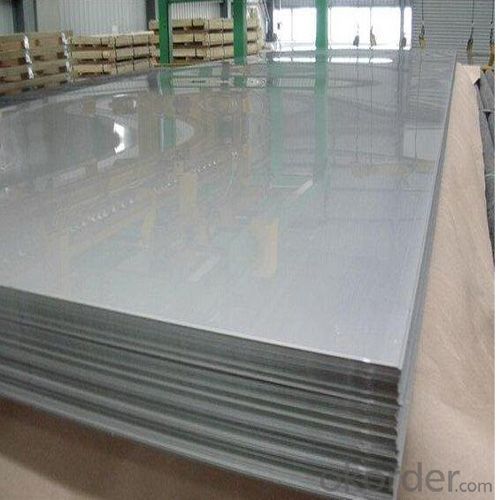

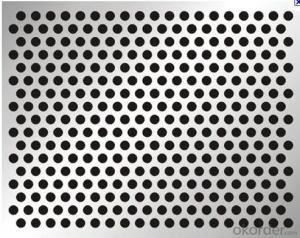

3. Customizable Aluminium Sheet Plate for Construction Images:

4. Customizable Aluminium Sheet Plate for Construction Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets suitable for pharmaceutical packaging?

- Indeed, aluminum sheets are apt for pharmaceutical packaging. The pharmaceutical industry extensively utilizes aluminum owing to its distinctive attributes. As a lightweight material, it offers exceptional safeguarding against moisture, oxygen, and light. Consequently, it becomes an ideal choice for packaging delicate pharmaceutical products that necessitate superior protection and stability. Additionally, aluminum sheets exhibit remarkable resistance to corrosion and boast commendable heat conductivity, facilitating efficient heat sealing in the packaging procedure. Moreover, aluminum is non-toxic and non-reactive, guaranteeing the safety and soundness of pharmaceutical items. In summary, aluminum sheets emerge as a dependable and frequently employed substance for pharmaceutical packaging.

- Q: Are aluminum sheets suitable for automotive applications?

- Aluminum sheets are indeed suitable for automotive applications. Aluminum, being a lightweight material, presents several advantages for automotive use. To begin with, aluminum boasts exceptional resistance against corrosion, making it an excellent choice for exterior parts that are exposed to harsh environments. Moreover, aluminum offers a remarkable strength-to-weight ratio, ensuring high durability while keeping the overall weight of the vehicle at a minimum. Consequently, this results in enhanced fuel efficiency and superior performance. Furthermore, aluminum sheets are highly malleable, enabling manufacturers to fashion intricate shapes and designs for a variety of automotive components. Additionally, aluminum is recyclable, making it a sustainable option for the environment. All in all, the utilization of aluminum sheets in automotive applications provides numerous benefits, including weight reduction, improved fuel efficiency, resistance to corrosion, and flexibility in design.

- Q: Can the aluminum sheets be used for manufacturing food packaging?

- Yes, aluminum sheets can be used for manufacturing food packaging. Aluminum is a popular choice for food packaging due to its non-reactive nature, resistance to corrosion, and ability to maintain the freshness and quality of food products.

- Q: I have heard that consuming aluminum can increase your risk for Alzheimer's later in life.Knowing this, would it increase my risk to eat sweet potatoes cooked in aluminum foil?Even if there is a negligible risk, I still want to know for curiosity reasons.Thank You

- No, I don't think it is dangerous to eat food baked in either side (shiny or matte side) in an aluminum foil. It is dangerous though to put aluminum foil inside a microwave oven to cause those electromagnetic fields to catch fire unless you have a microwave with a cavity magnetron tube to reflect the electromagnetic fields and also don't try to chew and ingest the aluminum foil

- Q: What are the necessary safety measures to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, it's crucial to wear appropriate personal protective equipment (PPE), including gloves to prevent cuts and eye protection to shield against flying debris. Ensure good ventilation to avoid inhaling dust or fumes from cutting or polishing. Use sharp tools to minimize the risk of accidents and always cut away from your body. Keep the work area clean and free of clutter to prevent slips or trips. Be cautious of electrical hazards if using power tools, and ensure all tools are properly grounded. Finally, be aware of the fire hazard potential of aluminum dust and store it safely away from ignition sources.</p>

- Q: could magnet attract iron with the seperation of rubber and aluminum sheets?

- no problem.

- Q: What are the different methods of surface cleaning for adhesive bonding of aluminum sheet?

- There are several methods of surface cleaning for adhesive bonding of aluminum sheet. These methods include mechanical cleaning, chemical cleaning, and conversion coating. Mechanical cleaning involves using abrasive materials or techniques such as sanding, wire brushing, or blasting to remove any dirt, debris, or oxidation from the surface of the aluminum sheet. Chemical cleaning involves using solvents or detergents to dissolve and remove contaminants from the surface. Conversion coating methods, such as phosphating or chromating, create a protective layer on the surface of the aluminum sheet, improving its adhesion properties and resistance to corrosion.

- Q: What are the different heat treatment options available for aluminum sheets?

- There are several heat treatment options available for aluminum sheets, each offering different properties and characteristics to the material. 1. Annealing: This process involves heating the aluminum sheet to a specific temperature and then slowly cooling it down. Annealing helps to relieve internal stresses in the material and improve its ductility and machinability. 2. Solution Heat Treatment: This treatment involves heating the aluminum sheet to a high temperature and then rapidly quenching it in water or other cooling media. Solution heat treatment is commonly used to dissolve and homogenize any alloying elements present in the aluminum, resulting in improved strength and hardness. 3. Precipitation Hardening: Also known as age hardening, this treatment is typically performed after solution heat treatment. It involves heating the aluminum sheet at a lower temperature for a specific period, allowing the alloying elements to precipitate and form fine particles. This process increases the strength and hardness of the aluminum without sacrificing its ductility. 4. Stress Relieving: This treatment is performed to relieve residual stresses that may have developed during fabrication or machining processes. The aluminum sheet is heated to a specific temperature and then slowly cooled down, reducing the risk of distortion or cracking. 5. Hardening: By heating the aluminum sheet to a specific temperature and then rapidly quenching it, hardening can be achieved. This process increases the strength and hardness of the material, making it more suitable for applications that require high strength-to-weight ratios. It is important to note that the specific heat treatment option chosen for aluminum sheets depends on the desired properties and application requirements. Consulting with a metallurgical expert or referring to the material's specifications can help determine the most suitable heat treatment option.

- Q: Are aluminum sheets suitable for lightweight structures?

- Indeed, aluminum sheets prove to be a fitting choice when it comes to lightweight structures. Renowned for its low density and impressive strength-to-weight ratio, aluminum emerges as an optimal material for applications requiring reduced weight. Industries such as aerospace, automotive, and construction frequently rely on aluminum sheets due to their exceptional corrosion resistance, durability, and malleability. These properties facilitate effortless fabrication and installation. Moreover, the versatility of aluminum sheets extends to their effortless joining through diverse welding and adhesive methods, thereby bolstering their aptness for lightweight structures.

- Q: Are 101 aluminum sheets suitable for agricultural machinery?

- Indeed, agricultural machinery finds suitability in a total of 101 aluminum sheets. Aluminum, a material that is both versatile and lightweight, brings forth numerous advantages for agricultural machinery. Its outstanding resistance to corrosion becomes particularly vital for equipment that confronts diverse weather conditions and chemicals commonly encountered in the agricultural industry. Furthermore, the strength-to-weight ratio of aluminum proves to be advantageous, permitting an augmented payload capacity and enhanced fuel efficiency. Moreover, the malleability of aluminum allows manufacturers to fashion intricate shapes and designs for machinery components. All in all, the durability, corrosion resistance, and versatility demanded by agricultural machinery are adequately met by 101 aluminum sheets.

Send your message to us

Customizable Aluminum Sheets in Minnesota for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords