Custom Rolled Aluminum Coil - Mill Finish Aluminum Coil 3003 H14 for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Coil 3003 H14 for Color Coating

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Mill Finish Aluminium Coil 3003 H14 for Color Coating

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Coil 3003 H14 for Color Coating

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

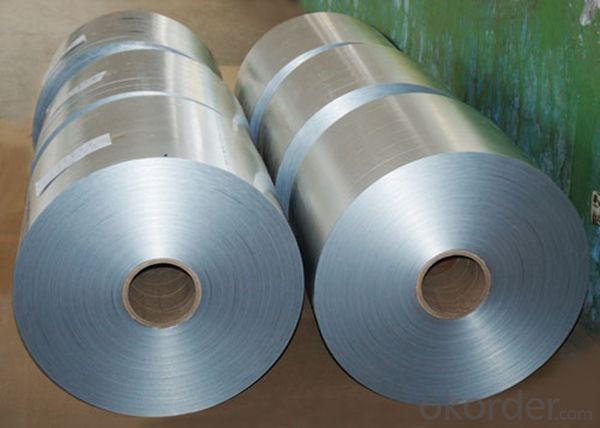

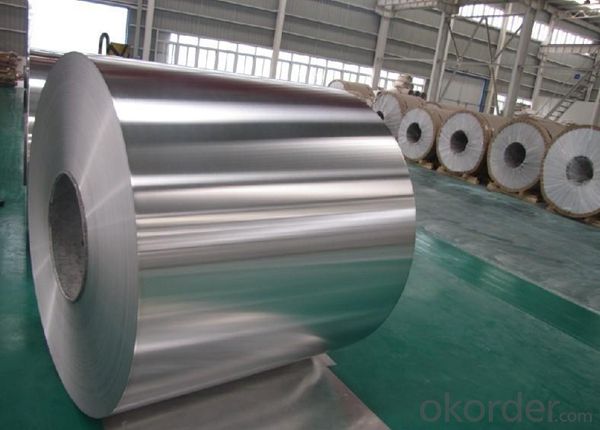

5. Image of Mill Finish Aluminium Coil 3003 H14 for Color Coating

6. Package and shipping of Mill Finish Aluminium Coil 3003 H14 for Color Coating

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils resistant to oil and grease?

- Aluminum coils typically possess resistance against oil and grease. They exhibit a natural ability to resist corrosion and are not easily influenced by most solvents, including oil and grease. This characteristic renders aluminum coils a suitable option for diverse applications that involve potential contact with oils or greases, such as the automotive and HVAC sectors. Nevertheless, it is crucial to acknowledge that extended exposure to particular aggressive chemicals or high concentrations of oil or grease may gradually result in damage or deterioration of the aluminum coils. Consequently, it is advisable to diligently clean and maintain the coils to guarantee their optimal functioning and durability.

- Q: Are there any restrictions on the coil flatness of aluminum coils?

- Yes, there are restrictions on the coil flatness of aluminum coils. The industry standards specify acceptable tolerances for coil flatness to ensure the quality and usability of the aluminum coils. These restrictions help prevent any deformation or irregularities in the coils, ensuring they meet the required specifications for various applications.

- Q: Are there any health or safety concerns related to aluminum coils?

- Aluminum coils have the potential to present health and safety risks, particularly in certain situations. One concern is the possibility of aluminum particles or fumes being released into the air, especially during the manufacturing or processing of the coils. Inhaling these particles or fumes could result in respiratory problems or lung damage. Moreover, damaged or corroded aluminum coils might release aluminum ions into food or drinks, which could be harmful if consumed excessively. Nonetheless, it is worth noting that the risks associated with aluminum coils are generally minimal and can be reduced through proper handling and upkeep. Manufacturers typically implement various safety measures to prevent the release of aluminum particles or fumes during production. Additionally, aluminum coils used in heating, ventilation, and air conditioning systems are usually coated or treated to prevent corrosion and the subsequent leaching of aluminum ions. To minimize any potential health risks, it is advisable to adhere to safety guidelines provided by manufacturers. This may involve wearing appropriate protective gear when handling aluminum coils and ensuring adequate ventilation in areas where they are processed or installed. Regular inspection, cleaning, and maintenance of the coils can also help identify and resolve any potential issues before they become a matter of health or safety. In conclusion, although there are concerns regarding the health and safety implications of aluminum coils, these risks can be managed through proper handling, maintenance, and adherence to safety guidelines. Seeking advice and recommendations from professionals or manufacturers regarding the utilization and upkeep of aluminum coils is always recommended to ensure maximum safety.

- Q: What is the primary substance that constitutes an aluminum coil?

- <p>The material of aluminum coil is aluminum, a lightweight, corrosion-resistant, and malleable metal. It is commonly used in various industries due to its excellent electrical conductivity, thermal conductivity, and formability. Aluminum coils are made by rolling aluminum sheets into cylindrical shapes, which can be further processed into different products such as cans, foils, and other applications.</p>

- Q: Can aluminum coils be used for automotive body panels?

- Certainly, automotive body panels can be made using aluminum coils. In fact, aluminum is gaining popularity in the automotive sector due to its numerous advantages. Its lightweight nature contributes to enhanced fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits exceptional resistance to corrosion, making it a durable option for automotive body panels. Additionally, aluminum can be easily shaped and molded, enabling intricate designs and improved aerodynamics. All in all, utilizing aluminum coils for automotive body panels presents a viable choice with a multitude of benefits.

- Q: my homework was to find out how do you get aluminium for rocks! I've been looking around but every web site i've been on only says that aluminium comes from rocks, but it doesn't say how you get it from rocks.e.g you get wool from sheep by shearing of their coat.so if anyone knows how you get aluminum from rocks please tell me i need your help.

- Aluminum is derived from a rock called Bauxite, which consists of a mixture of up to three aluminum minerals. Bascally they mine it, smelt it (heat to very high temperatures) and you get aluminum. You'll probably get a better answer form someone who is more familiar with the process, but that's a very rough idea.

- Q: What are the different color options for coated aluminum coils?

- The different color options for coated aluminum coils are vast and varied. They can include classic colors such as white, black, and gray, as well as an array of vibrant and bold shades like red, blue, green, and yellow. Additionally, there are also metallic finishes available that can add a touch of elegance and sophistication to the coils. Ultimately, the color options for coated aluminum coils are limited only by the imagination and preferences of the customer.

- Q: Is it safe and practical to use aluminum coil in cooking processes?

- <p>Aluminum coil can be used for cooking, but it's important to consider the specific type and context. Aluminum foil, for example, is commonly used for cooking in various forms such as wrapping food for baking or grilling, or lining baking sheets to prevent sticking. However, aluminum cookware is less common due to concerns about aluminum's potential health effects and its reactivity with certain foods. When using aluminum coil for cooking, ensure it's food-grade and avoid using it with acidic or alkaline foods, as this can lead to leaching of aluminum into the food. Always check the manufacturer's guidelines for safe use.</p>

- Q: Aluminum coil thickness measurement, real-time measurement of aluminum coil thickness value, you can use displacement sensor?

- You should use the eddy current displacement sensor KD2306 if the object is aluminum,

- Q: hey, my dad and i are working on painting our front door and the current piece of aluminum in front of it wont go with the new color. it doesnt look like it can be changed out so we are wondering, other than spray paint, what can you put on aluminum to make it turn permanently black. my dad mentioned gun blue, but that only works on steel. thanks

- Aluminum okorder / You could take it to someone that powder coats metals.

Send your message to us

Custom Rolled Aluminum Coil - Mill Finish Aluminum Coil 3003 H14 for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords