Aluminum Steel Coil - Mill Finish Aluminum Coils 3003 H14 H24 Factory Selling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Coils 3003 H14 H24 Factory Selling

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Mill Finish Aluminum Coils 3003 H14 H24 Factory Selling

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Coils 3003 H14 H24 Factory Selling

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

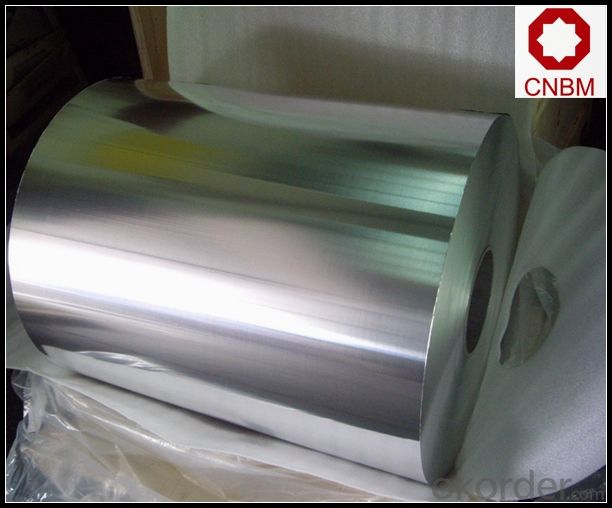

5. Image of Mill Finish Aluminum Coils 3003 H14 H24 Factory Selling

6. Package and shipping of Mill Finish Aluminum Coils 3003 H14 H24 Factory Selling

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils processed to achieve desired mechanical properties?

- Various techniques are employed to process aluminum coils in order to attain the desired mechanical properties. One method commonly utilized is known as annealing, wherein the coils are heated to a specific temperature and then gradually cooled. This particular process aids in reducing internal stresses and enhancing the metal's ductility and toughness. Another significant procedure is cold rolling, whereby the coils are passed through a series of rollers at room temperature to decrease their thickness and improve their mechanical properties. Not only does this technique bolster the aluminum's strength, but it also enhances its surface finish. To further augment the mechanical properties, aluminum coils can also undergo alloying. This involves blending the aluminum with other elements such as copper, manganese, or magnesium to form specific alloys. These alloys provide superior strength, corrosion resistance, and other desirable properties. Furthermore, heat treatments like precipitation hardening can be applied to aluminum coils. This process necessitates heating the coils to a specific temperature and maintaining them at that level for a certain duration, followed by rapid cooling. Precipitation hardening enables the formation of fine particles in the metal's microstructure, thereby increasing its strength and hardness. Lastly, surface treatments like anodizing or painting can be employed on aluminum coils to enhance their mechanical properties. Anodizing creates a protective oxide layer on the surface, improving corrosion resistance, while painting offers additional protection and aesthetic appeal. In conclusion, aluminum coils are subjected to various techniques including annealing, cold rolling, alloying, heat treatments, and surface treatments to achieve the desired mechanical properties. These processes serve to enhance the aluminum's strength, ductility, toughness, and corrosion resistance, rendering it suitable for a wide array of applications.

- Q: The specification of thermal insulating aluminum coil

- 4-0 In general, the chemical engineering products for thermal insulation is 0. According to the International standard, the thickness tolerance is +-5%.02MM. according to industrial standard, it is +-0. The production crafts are embossed and plain sheet.

- Q: Are aluminum coils prone to corrosion?

- Yes, aluminum coils are prone to corrosion. Aluminum is a reactive metal that tends to oxidize when exposed to oxygen and moisture, leading to the formation of a layer of corrosion on the surface of the coil. However, this can be mitigated by applying protective coatings or using alloys that are more resistant to corrosion.

- Q: when ferrous sulfate is poured into an aluminium can, holes appear in the can. Why?

- aluminum reacts via a redox reaction with iron(II): 3 Fe2+(aq) + 2 Al(s) --- 3 Fe(s) + 2 Al3+(aq)

- Q: What are some normal everyday products made from aluminum that I can use to recycle?

- cool drink cans.

- Q: Can aluminum coils be used in the production of beverage cans?

- Yes, aluminum coils can be used in the production of beverage cans. Aluminum is a preferred material for the manufacturing of beverage cans due to its lightweight, durability, and ability to preserve the taste and quality of the contents. Coils made of aluminum are typically used in the canning process as they can be easily shaped into a can form. The coils are rolled into sheets, which are then cut and formed into cans. Aluminum coils also have excellent heat conductivity, allowing for efficient cooling and faster production speeds. Overall, aluminum coils are an essential component in the production of beverage cans and are widely used in the industry.

- Q: Can aluminum coils be welded or soldered?

- Yes, aluminum coils can be welded or soldered. Welding and soldering are two common methods used to join aluminum coils together. Welding involves melting the aluminum material in the coils and fusing them together using heat and pressure. This process requires specialized equipment and skilled operators. On the other hand, soldering is a process that uses a lower melting point filler material, called solder, to join the aluminum coils. Soldering is typically used for lighter applications and requires less heat than welding. Both welding and soldering can effectively join aluminum coils, but the choice between the two methods depends on the specific requirements of the project, the equipment available, and the expertise of the operator.

- Q: So i like eating frozen foods like wings or bagel bites and i cook them in my toaster oven with aluminum foil under them on top of the tray. I heard using aluminum is bad for you and can get you diseases or illnesses. Is this true and should i stop using aluminum foil? i eat these frozen foods maybe 3-4 times a week

- No, aluminum foil and aluminum cookware are safe to cook with. Back in the 1930s to as late as the 1960s, a certain screwball religious cult sometimes published articles to fluff out their newsletters and proselytizing magazines about the supposed dangers of aluminum cookware. Their source was anecdotes from one obsessive quack, not any replicable scientific studies.

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Yes, aluminum coils are suitable for pharmaceutical vial caps. Aluminum is a preferred material for pharmaceutical packaging due to its excellent barrier properties, which help to protect the contents of the vials from moisture, oxygen, and other contaminants. Aluminum coils can be easily formed into caps of various sizes and shapes to fit different vial types. Additionally, aluminum is a lightweight material, making it convenient for transportation and handling. Moreover, aluminum is resistant to corrosion, ensuring the integrity of the vial caps during storage and use. Overall, aluminum coils are a suitable choice for pharmaceutical vial caps due to their barrier properties, versatility, and durability.

- Q: What type of equipment is used to process aluminum coils?

- The type of equipment commonly used to process aluminum coils includes slitters, cut-to-length lines, roll formers, and annealing furnaces.

Send your message to us

Aluminum Steel Coil - Mill Finish Aluminum Coils 3003 H14 H24 Factory Selling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords