Color Coated Aluminum Coil - Mill Finish Aluminum 3003 H14 China Factory Direct Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum 3003 H14 China Factory Direct Supply

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminum 3003 H14 China Factory Direct Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum 3003 H14 China Factory Direct Supply

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

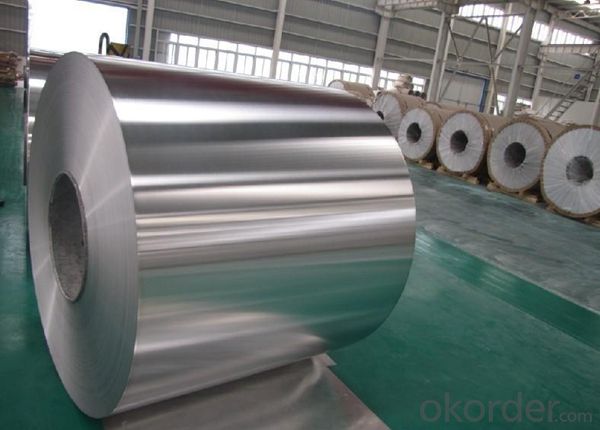

5. Image of Mill Finish Aluminum 3003 H14 China Factory Direct Supply

6. Package and shipping of Mill Finish Aluminum 3003 H14 China Factory Direct Supply

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum's low coefficient of friction and excellent thermal conductivity make it a suitable material for various applications where low friction is desired, such as in sliding mechanisms, bearings, and electrical connectors.

- Q: Are there any specific regulations for the disposal of aluminum coil waste?

- Yes, there are specific regulations for the disposal of aluminum coil waste. It is important to adhere to local environmental laws and regulations, which typically require proper handling, storage, and disposal methods for aluminum coil waste. This may include recycling or sending the waste to licensed facilities for proper treatment and disposal. It is recommended to consult with local authorities or waste management agencies for specific guidelines and requirements.

- Q: Can aluminum coils be used in the manufacturing of cans?

- Aluminum coils play a crucial role in the production of cans. They are commonly utilized to manufacture thin aluminum sheets, which are subsequently molded into cans. To achieve the desired thickness and width for can production, the coils undergo a series of steps, including rolling, annealing, and slitting. Once the aluminum sheets are prepared, they are cut into suitable sizes and shaped into the familiar cylindrical can form. Aluminum is a favored material for can manufacturing because of its lightweight, durable, and corrosion-resistant properties. Moreover, it serves as a protective barrier against light, oxygen, and moisture, thus ensuring the preservation of the contents' quality and shelf life. In summary, aluminum coils are an indispensable element in the can manufacturing process and play a significant role in the packaging industry.

- Q: What are the different coil handling options available for aluminum coils?

- Aluminum coils have several options for handling, depending on the user's preferences and specific requirements. Some commonly used options include: 1. Coil Cradles: These are horizontal racks or frames that provide support and stability for aluminum coils during storage or transportation. They come in various sizes and designs to accommodate different coil dimensions. 2. Coil Cars: These mobile platforms have lifting mechanisms to easily move aluminum coils between different processing stations. They can be manually operated or automated, depending on the desired level of automation. 3. Coil Turnstiles: These rotating devices hold multiple coils vertically, allowing for easy access to individual coils without heavy lifting or rearranging. They are ideal for high-volume production environments that require quick coil changeovers. 4. Coil Upenders: Specialized equipment used to rotate or flip aluminum coils to change their orientation. They are useful for loading or unloading coils in a vertical position or for specific processes that require a particular coil orientation. 5. Coil Lifters: Specifically designed lifting devices for aluminum coils. They have adjustable arms or clamps to securely grip the coil for safe and efficient lifting. Available in manual, semi-automatic, and fully automated models. 6. Coil Tippers: Used to tilt or incline aluminum coils for various purposes such as coil feeding or inspection. They can be operated manually or powered by hydraulic or pneumatic systems. 7. Coil Stackers: Used to neatly stack and store aluminum coils vertically. They have adjustable arms or forks to accommodate different coil sizes, optimizing storage space and ensuring easy access when needed. These examples showcase the variety of coil handling options available for aluminum coils. Each option has its own advantages and suitability for different applications or industries. Careful consideration of specific requirements and constraints is essential when selecting the most appropriate coil handling solution.

- Q: What are the different coil widths available for aluminum coils?

- The different coil widths available for aluminum coils can vary depending on the specific requirements and applications. However, common coil widths for aluminum coils range from as narrow as 1 inch (2.54 cm) to as wide as 72 inches (182.88 cm) or even wider in some cases.

- Q: Can aluminum coils be used for radiation shielding?

- Yes, aluminum coils can be used for radiation shielding. Aluminum is a commonly used material for radiation shielding due to its high atomic number and density, making it effective at absorbing and scattering radiation. Aluminum can effectively shield against a wide range of radiation types, including gamma rays and X-rays. Additionally, aluminum is a lightweight and malleable material, making it easy to work with and suitable for various applications where radiation shielding is required, such as in medical imaging, nuclear power plants, and aerospace industries.

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Pharmaceutical vial caps can indeed be made from aluminum coils. When it comes to pharmaceutical packaging, aluminum is highly favored thanks to its exceptional barrier properties. These properties effectively shield the vials' contents from moisture, oxygen, and other harmful substances. Aluminum coils can be easily molded into caps of various sizes and shapes, accommodating different types of vials. Another advantage is that aluminum is a lightweight material, which makes transportation and handling hassle-free. Additionally, aluminum is resistant to corrosion, ensuring that the vial caps remain intact throughout storage and usage. In summary, due to their barrier properties, versatility, and durability, aluminum coils are a suitable option for pharmaceutical vial caps.

- Q: If the aluminum coil is 220 kg, 0.3 thick and 500 wide, how much is the coil diameter?

- With the outer diameter and inner diameter, you can know the volume. With the density and volume, we can calculate the weight. And with weight, we can know the length.

- Q: So on friday we mixed crystaline copper chloride stuffs with water to make a clear blue solution. We then put some aluminum into the solution. The solution began to heat up and there was a redish brown precipitate at the end. What caused the heat? What was boiling? How does the mass of the original aluminum and original copper chloride crystaline stuff compare with the mass of the red/brown power stuff (we strained the liquid out), and the mass of the dried up blue stuff?

- You're looking at a redox reaction. During this process, the copper ions in solution are reduced to form copper metal (visible as dust) and the aluminum metal is oxidized to form aluminum ions. This process is exothermic due to the relative electron affinities and the positions on the activity sequence such that copper has a greater affinity for electrons and is a stronger oxidizing agent. I think aluminum forms a 3+ ion and copper forms either a 1+ or a 2+ ion. Copper's molecular weight is 63g/mol and aluminums weight is 27 g/mol. You would see the weight decrease because aluminum weighs less than Copper and is replaced less frequently due to the higher charge when you figure out the ionics. Nothing was boiling.

- Q: What are the typical dimensions for aluminum coils?

- <p>The standard size of aluminum coils can vary depending on the specific application and industry requirements. Commonly, aluminum coils are available in widths ranging from 600mm to 2000mm and thicknesses from 0.2mm to 6.0mm. The length of the coils can be from 500 meters to over 3000 meters, depending on the weight and the manufacturing process. It's important to note that these dimensions are not fixed and can be customized to meet specific project needs.</p>

Send your message to us

Color Coated Aluminum Coil - Mill Finish Aluminum 3003 H14 China Factory Direct Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords