CUMMINS generator with soundpfoof from Shanghai Ruiying 100kva

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low-noise 100kva Cummins Diesel Generator 50/60hz

Briefe performance of silent diesel generator set

1)High quality, steady and reliable performance

2)Blow 71dB at 7 meter

3) Perfect Maneuverability

4) Wide Application

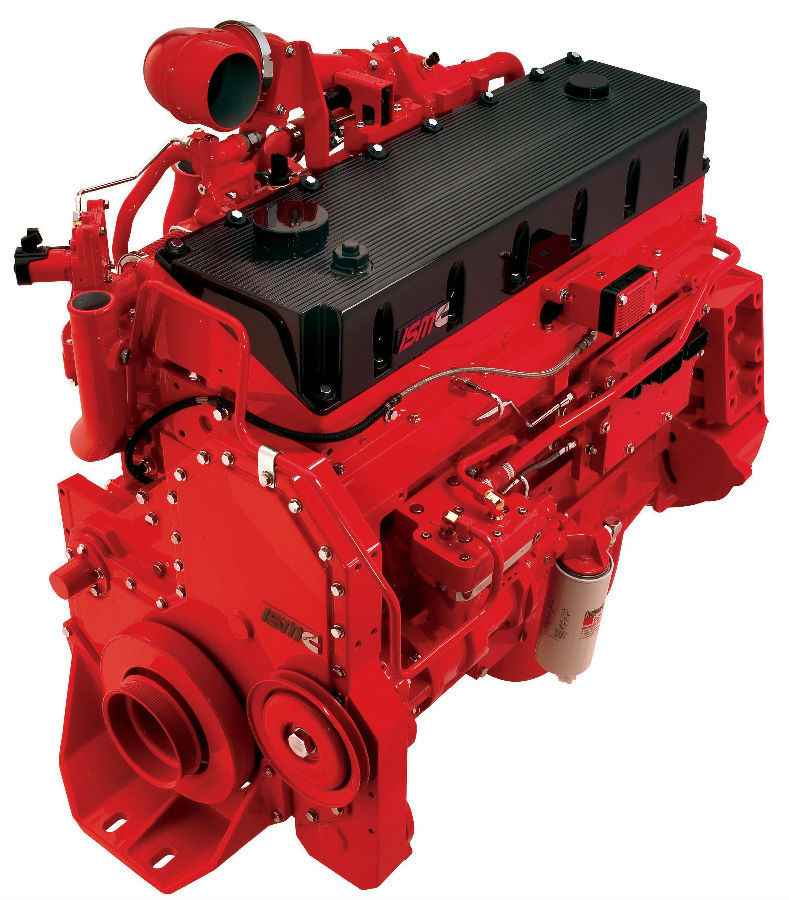

Cummins Engine

Alternator

Engine | CUMMINS 6BTA5.9-G2 |

Alternator | STAMFORD UCI274C |

Control system | SMARTGEN HGM6120KC |

Accessory | Fuel tank 600L Breaker TIANZHENG Start battery 100Ah×2 |

Manufacturer | CUMMINS | |

Model | 6BTA5.9-G2 | |

Cylinder and cycle type | 6 cylinders in line, 4 strokes | |

Aspiration and cooling | Turbocharged and after cooled | |

Displacement | 5.9 L | |

Bore×Stroke | 102×120 mm | |

Compression ratio | 17.5:1 | |

Rated speed | 1500 rpm | |

Governor | Electronic | |

Oil capacity | 16.4 L | |

Prime power | 90kW | |

Standby power | 99kW | |

Fuel consumption | 22L/H (100% Load) | 17L/H (75% Load) |

Coolant capacity | 9.1 L | |

Start system | DC 24V | |

Alternator Specifications:

Alternator Specifications:

Manufacturer | STAMFORD |

Model | UCI274C |

Type | Single bearing,4-pole,AC brushless and self-exciting |

Frequency | 50 Hz |

Power Factor | cosΦ=0.8 |

Phase | 3 |

Voltage | 400/230 V |

Capacity | 80kW/100kVA |

Insulation class | H |

Protection class | IP23 |

Elevation | ≤1000m |

Control System(DSE from UK)

HGM6120KC Control System is mainly used in generating supervising and control of land type diesel generator set and the switching between diesel generator set and city electricity supply. It is combined with digitalization, intelligence and network and capable of generator start and stop, generator data supervising and testing, protection alarm, city electricity supply quality supervising and starting generator automatically when power failure happens or city electricity supply is beside the set point.

Silent/Low noise generator

Light Tower with Trailer Generator Set

Trailer and low-noise generator

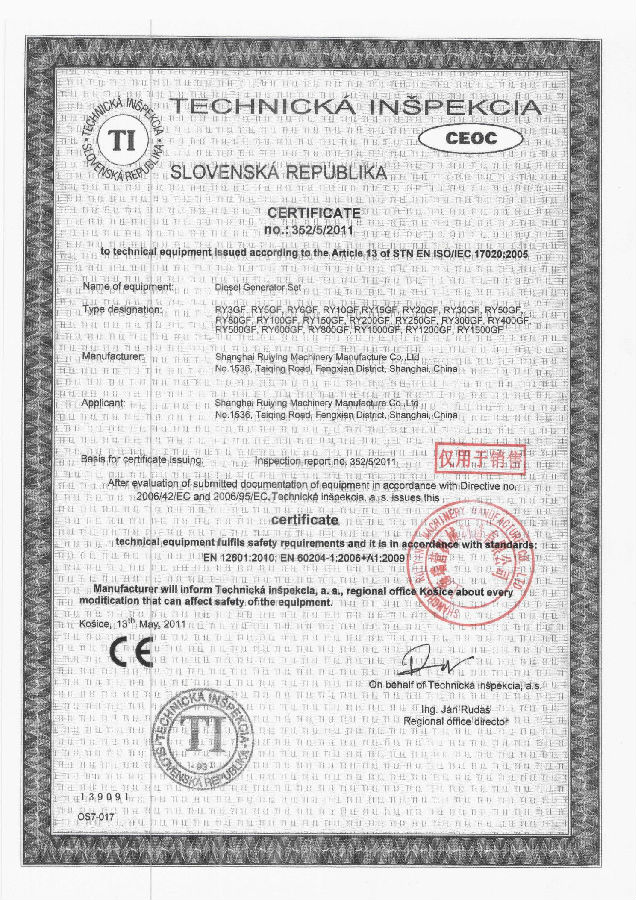

Certifications

Our Factory

- Q: ac condenser fan motor runs when outside temp is cooler, what causes it NOT to run?

- The AC condenser motor or air handler motor runs only when the AC compressor is running (or heat pump is operating). Otherwise, they remain off. Has nothing to do with outside air temperature. If the motor doesn't run, it could be a bad motor, motor capacitor, motor control relay. Split AC units have three motors - compressor motor, condenser motor, air handler motor (blows air into the home through the duct work). Single unit AC systems have two motors - compressor motor and a single motor that operates the fans for the condenser and air handler.

- Q: What are the differences between AC motors and DC motors?

- DC motor installed a constant magnetic field, current in the stator coil of electromagnetic force is created, it will move, but the direction of the current to continue to change, so will the use of brush, contact terminals. Therefore, the cost of construction is relatively high. Generally used in servo motor, speed measuring motor and excitation motor more.

- Q: what are the applications of ac dynamic braking?

- I assume that you are asking about dynamic braking of an AC motor. The term “dynamic braking” is usually applied where braking energy is dissipated as heat in resistors. Where braking energy is returned to the power supply, the term “regenerative braking” is usually used. “DC braking” of an AC induction motor refers to braking by applying DC current to the motor windings. Dynamic and regenerative braking can only be implemented when the motor is controlled by a variable frequency drive (VFD). Because the braking energy can not be reused, dynamic braking is used in applications that do not generate a lot of braking energy or do not have a means for storing braking energy or using it elsewhere. A relatively simple control unit is used to connect the braking resistors and modulate the braking current when braking is required. Regenerative braking requires a more complicated control unit unless the VFD is DC powered.

- Q: Can the voltage regulating module be used as AC motor speed regulation?

- Want to control motor speed, only changing voltage frequency on the stator can (with more of a V/F control, change the frequency corresponding to the change of voltage amplitude), change the voltage regulator will not only change the frequency, voltage, it will only change the motor torque (the size of the voltage will not change, otherwise it will cause the stator coil current is too large; for example, if you burn the motor) with voltage regulator voltage applied to the motor will change the speed two times, will have little change but far less than the two times. When using the voltage regulator experiment, do pay attention to the rated voltage of the motor, otherwise it may cause permanent damage to the motor!

- Q: how to select the number of turns, height of the core, size of the copper wire. and tell me hoe to reduce tghe noise in AC unjiversal motor

- Money, money, and money. How much are you willing to spend?

- Q: I need to reduce the speed of a mechanical timer for a dish sanitizer by about 30%. Its an AC 240v gear motor and draws way less than an amp. (its about the size of a plum) My first thought was to add a potentiometer but that apparently only works on DC motors?

- I don't see why it wouldn't work. They have a couple fan controls at home depot also, may save you a few bucks...other than that why not replace the timer? Something a little more variable...

- Q: If the volts and amp (rms) have been given on continous basis..Is it electrical load/input a motor can sustain?If HP is given tehn woud it be shaft power

- Continuous means that the motor may be run at full load continuously. It is not an intermittent-duty motor. The horsepower (HP) rating is the mechanical output power that the motor can deliver at the shaft. Volts is the nominal voltage at which the motor is designed to run. Usually there is a +/-10% tolerance on that value. Amps is the value of current that the motor will draw when the motor is mechanically loaded to 100%, with rated voltage and frequency applied to the motor.

- Q: Lets say for Airport applications what kind of Motors would be used to run the conveyors? for stop start conveyors used in sorting the baggage would they use DC motors? any idea of the type and power would be helpful. Also for the ones that would maybe be running a large conveyor line like the carousel where you collect your baggage? would that use AC or DC motors, and Im wondering what type and power?

- Conveyor Motors

- Q: I've heard that hair dryers with AC motors are better then dryers with DC motors. Why? Is it just because they last longer?

- Advantages of AC motors: Simple Design Low Cost Reliable Operation Easily Found Replacements Variety of Mounting Styles Many Different Environmental Enclosures Disadvantages of AC motors: Expensive speed control Inability to operate at low speeds Poor positioning control Advantages of DC motors: Easy to understand design Easy to control speed Easy to control torque Simple, cheap drive design Disadvantages of DC motors: Expensive to produce Can't reliably control at lowest speeds Physically larger High maintenance Dust I know this is a little much for talking about hair dryers, but it is some basic information. For more check the link below:

- Q: I found synchronous motor used as simple AC squirrel cage induction motor. the rotor of syn motor got damaged. I replaced the rotor by an equivalent rotor of squirrel cage induction motor. To my surprise I found motor drawing no load current as 60-65% of its rated current. What must have gone wrong?

- If you fit an armature from an induction motor into the stator of a synchronous motor with the same number of poles, then you will end up with an induction motor (which will run always slower than a synchronous motor; about 2800 rpm as opposed to 3000). But if the number of poles does not match, then you will end up with a rather inefficient machine. Moral of story: Replace a faulty part with the proper part.

Send your message to us

CUMMINS generator with soundpfoof from Shanghai Ruiying 100kva

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords