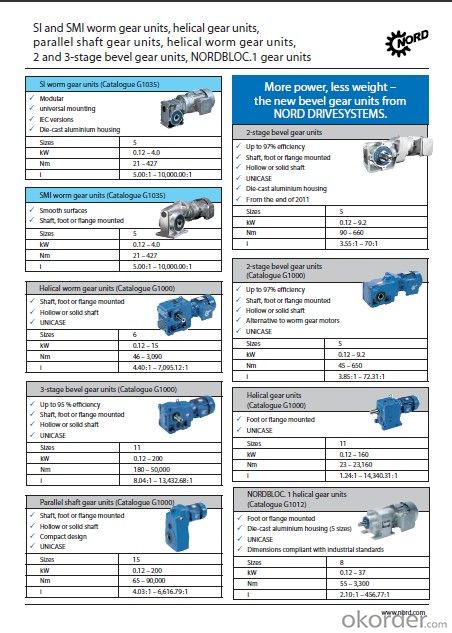

Worm gear units

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Okay well first off our ac was running awesome and then one day the unit stopped spinning outside so we called a professional he came out and said that the capacitator(not sure how to spell it) burnt up which was not uncommon in this heat then he said we needed to change our filters he hosed it all down recharged the freon, a week later it compeltely freezes up, the outside unit was spinning but nothing was coming out of the vents , so we let it thaw out call him he comes out says our blower motor was getting stuck so he readjusted it said it was working already cooling our house down! Awesome except it froze up again! So we call him again and he tells us that our blower motor in our furnace needed replaced, so we replaced that ... We fall asleep to a hot house hoping it would get cooler threw the night w our running ac again only to wake up to it being frozen again ..... Please help ...

- You AC guy, like most others I've run across, has absolutely no idea what's wrong with your system. They are taught in AC school that if this happens, replace that. If that happens, replace this. They are not taught HOW TO TROUBLESHOOT! I've had so called AC techs try to tell me that the motor will cause the capacitor to fail or the capacitor will cause the motor to fail. I've been in electronics for 43 years. It will not. A failed capacitor will prevent the motor from starting or running. Sure, he replaced the capacitor because the motor stopped running - it's a run capacitor needed for the motor. That was the easy part. Cleaning the coils by hosing them down is a maintenance action, not a repair action, unless it was extremely clogged with dirt. I doubt the blower motor was getting stuck and needed adjusting. There is no adjustments for AC motors. If the motor was bad, he should have caught that on the 1st visit. You may have bought a motor you didn't need. He's cleaned the coils and recharged the system (which I doubt was he problem either). I'm not an AC tech, but I believe you have a restriction in the refrigerant line going to the evaporator. That restriction is acting like the expansion valve causing the evaporator to ice up. A plugged or severely restricted expansion valve itself may be the problem. That's what the problem was with my unit. The restriction could also be a kinked refrigerant line going to the evaporator - that was the problem with my daughter's unit. IT'S NOT YOUR COMPRESSOR. The fact that you can create ice tells me the compressor is working. But if the problem isn't fixed soon, you could lose the compressor due to high head pressures caused by the icing problem.

- Q: What is ac servo motor?

- its a vacuum canister with a diaphragm inside it, the vehicles vacuum pulls the diaphragm back. usually the diaphragm is connected to something that moves, like a door in the heater or ac system or even an arm on a heater control valve or on the cruse control system that pulls the throttle back and holds it there. the old corvettes has this type system to open and close the headlights. other vehicles had the same type lights, mercury and olds. this system may be called something else in different areas.

- Q: It's a 1kW single phase AC pump motor with a 100v supply. This is for a theory question btw. :)

- Depending on what type of motor you have, you can either adjust the amplitude of the AC sine wave or adjust the frequency of the AC sine wave.

- Q: I have a small 1/4 HP 220V AC motor, and I want to see if it will run on a regular household 120V AC circuit. Will it work?

- poorly. It will rotate slowly if at all, and may overheat. .

- Q: Explain how a phase shift between the current in the poles of a motor causes a rotating magnetic field to be created.

- This relates to an ac motor, (Alternating Current). The AC current has a sinusoidal wave, of 60 cycles per seconds(USA). Therefore the current is alternating from positive to negative once in each cycle. The coils in the field or armature of the motor, alternately create a magnetic field that alternate synchronously with the current, creating a N(pole) or a (S) pole magnet at the core of the coil. It is this alternating pole (N to S toN to S.....on and on )that creates the attraction or repulsion between the magnetic fields in the housing(stator) and rotor of the motor, causing the rotational movement. A direct current passing thru a coil which is wound around an iron core will produce a magnetic field that makes one end of the iron core as N(pole), the other as(S) pole, steadily. The same set up , but with an alternating current (A.C) will create alternating N pole, and S pole at the same end of the core, changing at the rate of the frequency of the ac supply.

- Q: How many kinds of braking modes are there in AC motors? What are the characteristics of each?

- Energy consumption brakingWhen the motor cuts off the AC power supply, a DC power supply is added to any two of the stator winding to generate a stationary magnetic field, and the stationary magnetic field is generated by the inertia rotation of the rotor to produce a braking torque

- Q: So, my old blower motor started smoking, and sparking, I took it in, and bought a new one, the guy also sold me a new capacator with it, and hooked it up for me... BUT I'm confused which wires go where. I took pictures..

- we've appropriate air inspite of the undeniable fact that it works besides as Bush being the President for the previous 7 years. No offense meant, stereotypically conversing. yet we bough an easily air conditioner for our abode. Sweeeet. :)

- Q: Where the fuse for the fan motorblower located on my 96 bonneville because i bough a new blower motor and its still not working

- ok examine it out, your blower motor is shot, come to bolster motor vehicle areas and we are able to positioned it in for unfastened. Disclaimer: in basic terms strengthen motor vehicle areas in hazel eco-friendly,al will try this till you're fortunate.

- Q: What are the classifications of AC motors?

- According to the different rotor structure, three-phase asynchronous motor can be divided into two major categories, squirrel cage and winding. Among them, squirrel cage is the most widely used.

- Q: the heater/ac fan quit working on my 1992 dodge dynasty. The fan motor is good, so what might be another problem?

- you probable have a foul blower motor resistor on it,that's what reasons that too take place,it knocks out all the different speeds for the blower motor,on that one it mounts style of at the back of the glove container,and is hung on by skill of two screws,its very virtually at the back of the glove container,yet you may get to it,it value around 20 greenbacks and takes under quarter-hour to alter,that furnish you with back all of the speeds,its not a foul restoration to could do,solid success with it.

Send your message to us

Worm gear units

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords