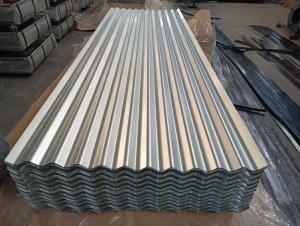

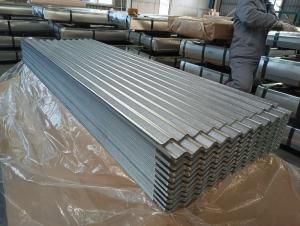

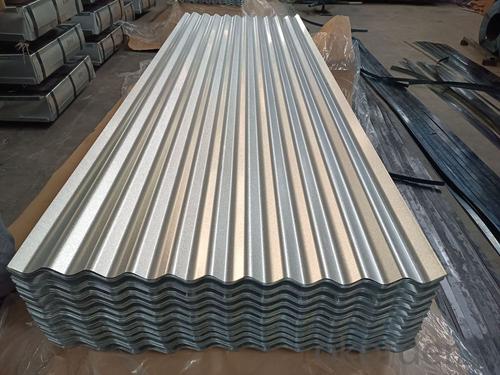

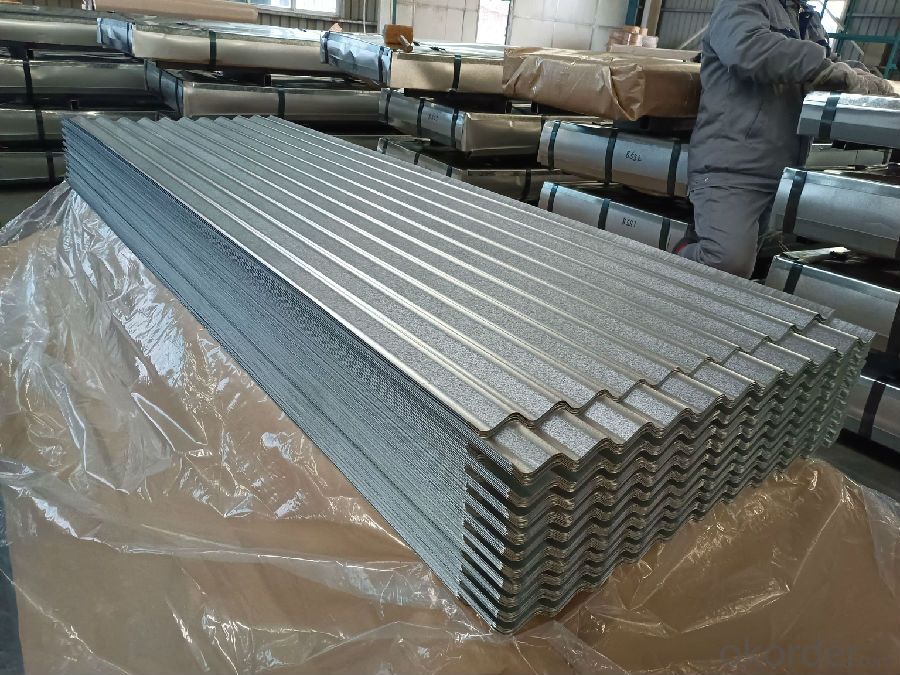

Corrugated Aluzinc Steel Sheet JIS G3321 Flat Sheet for Building & Roofing Material in Stock

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

In Stock & Fast Delivery

Steel Grade & Standard: JIS G3321

Zinc Coating Mass:AZ50g/m2 (+/-10g)

Surface Treatment: Unoiled,Chromated

0.25mm linear meter: 579m/mt 0.3mm linear meter: 481m/mt

WIDTH AFTER CORRUGATED: 800MM;

WIDTH BEFORE CORRUGARED:900MM

- Q: What is a steel sheet?

- A steel sheet is a flat, thin, and rectangular piece of steel that is manufactured through a process called hot rolling or cold rolling. It is commonly used in various industries such as construction, automotive, and manufacturing. Steel sheets are versatile and can be easily cut, bent, and shaped into different forms to meet specific requirements. They come in various thicknesses and sizes, and their durability and strength make them a popular choice for applications that require structural integrity and resistance to corrosion and wear. Steel sheets can be further processed through methods like galvanizing or coating to enhance their properties and protect them from rusting.

- Q: Can steel sheets be used for water tanks or storage containers?

- Yes, steel sheets can be used for water tanks or storage containers. Steel is a durable and strong material that can withstand the pressure and weight of holding water or storing various materials. It is commonly used in the construction of water tanks and storage containers due to its resistance to corrosion, ability to maintain structural integrity, and ease of maintenance. Steel sheets can be fabricated into different shapes and sizes to meet specific requirements, making them versatile for various applications. Additionally, steel is a recyclable material, which adds to its sustainability and environmental benefits.

- Q: What are the different sheet metal rolling techniques for steel sheets?

- Steel sheets can be rolled using different techniques, including hot rolling, cold rolling, and roll forming. Hot rolling involves heating steel sheets above their recrystallization temperature and passing them through rollers to reduce thickness. This method is commonly used to produce steel sheets with consistent thickness and improved mechanical properties. In contrast, cold rolling rolls steel sheets at room temperature. This process creates thinner and smoother sheets with higher dimensional accuracy. Cold-rolled steel is often used for applications that require a high-quality surface finish, such as automotive body panels and appliances. Roll forming is a continuous bending process where a long strip of steel is gradually shaped into a desired profile using rollers. This technique is suitable for producing steel sheets with complex shapes and profiles, like corrugated roofing or C-channel beams. Roll forming offers excellent precision and repeatability, making it a popular choice for mass producing steel sheets with consistent dimensions. Ultimately, the choice of rolling technique depends on the specific requirements of the application. Hot rolling is ideal for achieving uniform thickness and improved mechanical properties. Cold rolling is preferred for applications that demand high-quality surface finish and dimensional accuracy. Roll forming is suitable for creating steel sheets with complex shapes and profiles.

- Q: Are the steel sheets resistant to UV radiation?

- Yes, steel sheets are generally resistant to UV radiation. Steel is a highly durable material that can withstand exposure to various environmental factors, including UV radiation. However, the extent of resistance may vary depending on the specific type of steel and its protective coating. Steel sheets with a high-quality protective coating, such as galvanized or stainless steel, are more resistant to UV radiation compared to bare steel. These coatings act as a barrier, preventing UV rays from directly impacting the steel surface and reducing the likelihood of degradation or discoloration. Additionally, regular maintenance and proper care can further enhance the steel sheets' resistance to UV radiation, ensuring their long-term durability and performance.

- Q: What is the process of etching or engraving on steel sheets?

- The process of etching or engraving on steel sheets involves several steps to create intricate designs or patterns on the surface of the metal. Here is a general overview of the process: 1. Design and Preparation: The first step is to create or choose a design that will be etched or engraved onto the steel sheet. This design can be hand-drawn or created using computer software. Once the design is finalized, it is transferred onto a film or stencil. 2. Cleaning the Steel Sheet: Before beginning the etching or engraving process, the steel sheet needs to be thoroughly cleaned to remove any dirt, grease, or oxidation. This is typically done using a solvent or a degreasing agent to ensure a clean and smooth surface for the etching or engraving. 3. Applying the Stencil: The stencil or film with the desired design is carefully applied to the steel sheet. This stencil acts as a protective barrier, preventing the etching or engraving solution from affecting the areas that should not be etched or engraved. 4. Etching or Engraving Solution: A specialized etching or engraving solution is selected based on the desired effect and the type of steel being worked on. This solution is applied to the exposed areas of the steel sheet, where the stencil has not been applied. The etching or engraving solution chemically reacts with the steel, removing a thin layer of metal to create the desired design or pattern. 5. Control and Timing: The etching or engraving process requires careful control of factors such as temperature, time, and concentration of the solution. These parameters can affect the depth and quality of the etching or engraving, so it is crucial to closely monitor and adjust them as needed. 6. Rinsing and Cleaning: Once the desired etching or engraving depth is achieved, the steel sheet is thoroughly rinsed to remove any remaining solution. This step is essential to stop the chemical reaction and prevent any further etching or engraving. 7. Finishing Touches: After rinsing, the steel sheet may undergo additional steps to enhance the appearance of the etched or engraved design. This can include polishing, buffing, or applying protective coatings to improve durability and visual appeal. Overall, the process of etching or engraving on steel sheets requires precision, attention to detail, and the use of specialized tools and chemicals. It is a skillful art form that can produce stunning and intricate designs on steel surfaces.

- Q: Can steel sheets be used for storage shelves?

- Yes, steel sheets can be used for storage shelves. Steel is a strong and durable material that can withstand heavy loads, making it suitable for holding and organizing items on shelves.

- Q: How do steel sheets handle electromagnetic interference?

- Steel sheets are highly effective in handling electromagnetic interference (EMI) due to their inherent electrical conductivity and magnetic permeability. These properties allow steel sheets to act as a shield against electromagnetic waves and prevent their penetration into or out of an enclosed space. When exposed to EMI, steel sheets act as a barrier, reflecting and absorbing electromagnetic waves, thus minimizing their impact on electronic devices and systems. This shielding effect is particularly crucial in sensitive environments such as data centers, laboratories, or industrial facilities where electromagnetic interference can disrupt electronic equipment and compromise their functionality. The thickness and composition of the steel sheet also play a significant role in determining its effectiveness in handling EMI. Thicker sheets provide better shielding due to increased attenuation of electromagnetic waves. Additionally, certain types of steel alloys, such as carbon steel or stainless steel, offer enhanced EMI shielding capabilities. It is important to note that while steel sheets provide excellent EMI shielding, they are not entirely impervious to electromagnetic waves. Factors such as the frequency of the waves and the size of any openings or gaps in the steel sheet can affect their shielding effectiveness. Therefore, proper installation and grounding techniques are essential to ensure optimal EMI protection. Overall, steel sheets are a reliable choice for managing electromagnetic interference, making them a preferred material in various industries where EMI shielding is critical for the uninterrupted operation of electronic devices and systems.

- Q: Can steel sheets be used in HVAC systems?

- Yes, steel sheets can be used in HVAC systems. Steel is a commonly used material in HVAC systems for various components such as ductwork, air handling units, and heat exchangers. It is durable, strong, and can withstand high temperatures and pressures, making it suitable for HVAC applications.

- Q: How do you remove stains or marks from steel sheets?

- To remove stains or marks from steel sheets, you can start by cleaning the surface with a mild detergent and water solution. If the stains persist, you can try using a non-abrasive cleaner or a stainless steel cleaner specifically designed for removing stains. For tougher stains, you may need to use a soft cloth or sponge along with a mild abrasive cleaner. It's important to always follow the manufacturer's instructions and test any cleaner on a small, inconspicuous area before applying it to the entire surface.

- Q: What are the disadvantages of using steel sheets?

- Some disadvantages of using steel sheets include their tendency to rust and corrode over time, their relatively high cost compared to other materials, and their weight, which can make them difficult to handle and transport. Additionally, steel sheets may require special equipment and expertise for installation and maintenance.

Send your message to us

Corrugated Aluzinc Steel Sheet JIS G3321 Flat Sheet for Building & Roofing Material in Stock

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords