Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

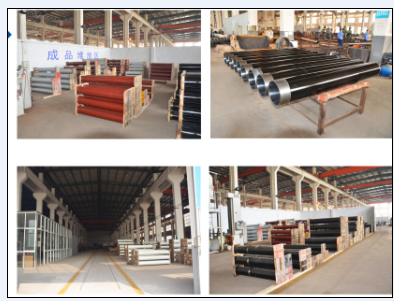

The Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM is a concrete pumping for combined use with other concrete pumps in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM

1. Life Span: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM

5. Material: Steel C45

6. Quenching and tempering to improve the hardness to HB241-280

7. Inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

Product Advantages:

OKorder'sConcrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN230*2100?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN230*2100?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders according to customers request?

A4: Yes, we can produce Cylinders according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q: Which is the best home made concrete pump car?

- The three line is nine and Keni Le, jiubang, Linuo, etc., in addition to cheap, many of the subsequent trouble

- Q: How often should concrete pump outriggers be inspected and maintained?

- Concrete pump outriggers should be inspected and maintained regularly, ideally before each use and at least once a month. This ensures their proper functioning and helps prevent any potential accidents or damage.

- Q: How often should I replace concrete pump spare parts?

- The frequency at which you should replace concrete pump spare parts depends on various factors such as the quality of the parts, the intensity of usage, and regular maintenance. Generally, it is recommended to conduct regular inspections and maintenance to identify any signs of wear or damage in the spare parts. As a preventive measure, it is advisable to replace parts that show significant wear or are no longer functioning optimally. However, it is crucial to follow the manufacturer's guidelines and recommendations for the specific concrete pump model you are using. Additionally, consulting with experienced professionals or technicians in the field can provide valuable insights on the expected lifespan of different spare parts and when replacements may be necessary.

- Q: What are the common signs of wear and tear on concrete pump spare parts?

- The common signs of wear and tear on concrete pump spare parts include cracks or fractures in the components, corrosion or rust on metal parts, excessive vibration or noise during operation, decreased performance or efficiency, and visible signs of wear on seals or gaskets.

- Q: Are there any specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts. Here are some general guidelines to follow: 1. Safety precautions: Always ensure that the concrete pump is turned off and depressurized before attempting to install any seal kits or O-rings. Wear appropriate safety gear, such as gloves and goggles, to protect yourself during the installation process. 2. Preparation: Thoroughly clean the area where the seal kits or O-rings will be installed. Remove any debris or old seal remnants to ensure a clean and smooth surface for installation. 3. Inspection: Before installing new seal kits or O-rings, inspect them for any defects or damage. If any issues are found, replace the faulty parts with new ones. 4. Lubrication: Apply a small amount of compatible lubricant or hydraulic oil to the seal kits or O-rings to aid in their installation and prevent damage during the process. Be sure to use a lubricant that is compatible with the materials used in the seal kits or O-rings. 5. Proper alignment: Carefully align the seal kits or O-rings with their respective grooves or seating areas in the concrete pump. Ensure that they are properly seated and positioned before proceeding. 6. Correct installation technique: Use the appropriate tools and techniques to install the seal kits or O-rings. Avoid excessive force or bending, as this can lead to damage or improper sealing. 7. Testing: After the installation is complete, test the concrete pump to ensure that the seal kits or O-rings are functioning properly. Check for any leaks or abnormal behavior during operation. 8. Regular maintenance: Once the seal kits or O-rings are installed, it is important to regularly inspect and maintain them to ensure their longevity and optimal performance. Follow the manufacturer's recommended maintenance schedule and guidelines for best results. It is important to note that these guidelines are general in nature and may vary depending on the specific make and model of the concrete pump. Therefore, it is always recommended to consult the manufacturer's instructions and guidelines for the particular seal kits or O-rings being installed.

- Q: What are the key factors to consider when purchasing concrete pump spare parts?

- When purchasing concrete pump spare parts, there are several key factors that need to be considered to ensure you make the right choice. These factors include: 1. Quality: The quality of the spare parts is crucial as it directly impacts the performance and longevity of your concrete pump. Look for high-quality materials and reputable brands to ensure durability and reliability. 2. Compatibility: It is essential to ensure that the spare parts you purchase are compatible with your specific concrete pump model. Check the specifications and consult with experts or the manufacturer to avoid any compatibility issues. 3. Cost-effectiveness: While it is important to consider the price of the spare parts, it should not be the sole determining factor. Look for a balance between cost and quality to ensure that you are getting value for your money in the long run. 4. Supplier reputation: Choose a reliable and reputable supplier who has a track record of providing genuine and high-quality spare parts. Read customer reviews, check their certifications, and consider their experience in the industry. 5. Availability and lead time: Ensure that the spare parts you need are readily available and can be delivered within a reasonable time frame. This is crucial to avoid delays in your construction projects and minimize downtime. 6. Warranty and after-sales support: Check if the spare parts come with a warranty or guarantee. Additionally, consider the availability of after-sales support and technical assistance in case you need any help or guidance during installation or maintenance. 7. Maintenance requirements: Consider the maintenance requirements of the spare parts you are purchasing. Look for components that are easy to install, maintain, and repair, as this can save you time and money in the long run. By considering these key factors, you can make an informed decision and ensure that you purchase the right concrete pump spare parts that meet your specific needs and requirements.

- Q: What is the function of a concrete pump remote control?

- A concrete pump remote control serves as a tool to operate and control the functions of a concrete pump from a distance. It allows the operator to manipulate various aspects of the pump's operation, such as starting and stopping the pumping process, adjusting the speed and direction of the pump, and controlling the placement and flow of the concrete. By providing remote control capabilities, it eliminates the need for the operator to be physically close to the pump, allowing for safer and more efficient operation. Additionally, the remote control often includes features such as emergency stop buttons, diagnostics, and data logging capabilities, which further enhance the functionality and reliability of the concrete pump. Overall, the function of a concrete pump remote control is to provide convenience, precision, and safety in the operation of concrete pumping equipment.

- Q: How is a concrete pump pipe different from a regular pipe?

- A concrete pump pipe is specifically designed for pumping high-pressure concrete mixture from a concrete pump truck to the desired location. Unlike a regular pipe, a concrete pump pipe is made of high-quality and durable materials such as hardened steel or alloy, which can withstand the high pressures and abrasion caused by the concrete mixture. One key difference between a concrete pump pipe and a regular pipe is the thickness of the walls. Concrete pump pipes have thicker walls to ensure they can handle the high pressure and abrasive nature of the concrete mixture. Regular pipes, on the other hand, are designed for various purposes such as water or gas transportation and therefore may not have the same level of thickness and durability. Additionally, concrete pump pipes often come with different end connections, such as flanges or couplings, to allow for easy connection and disconnection to the concrete pump truck and other pipeline components. This ensures a secure and leak-free transfer of the concrete mixture. Furthermore, concrete pump pipes may also have special design features to enhance their performance and longevity. These features can include wear-resistant linings, heat treatment, or galvanization to prevent corrosion and extend the lifespan of the pipe. In summary, a concrete pump pipe differs from a regular pipe in terms of its materials, thickness, end connections, and design features. These differences enable concrete pump pipes to handle the unique requirements of pumping high-pressure concrete mixtures efficiently and effectively.

- Q: What is the function of a concrete pump hydraulic accumulator?

- The operation of a concrete pump heavily relies on a crucial component known as the hydraulic accumulator. Its primary objective is to store and release hydraulic energy, which is instrumental in maintaining a seamless and uninterrupted flow of concrete during pumping activities. The hydraulic accumulator acts as a reservoir for pressure, being directly connected to the hydraulic system of the concrete pump. When the pump is not actively engaged, the accumulator stores hydraulic fluid that is pressurized. This accumulated energy can be unleashed when necessary, particularly during the pumping process, effectively providing supplementary power to the main hydraulic system. During concrete pumping, the accumulator proves invaluable in upholding a steady stream of concrete by compensating for any fluctuations in hydraulic system pressure. It functions as a buffer, absorbing any excessive pressure and subsequently releasing it back into the system whenever required. This mechanism is pivotal in averting sudden surges or drops in pressure, which could potentially lead to irregular concrete flow or even inflict damage upon the pump. Moreover, the hydraulic accumulator also contributes to reducing energy consumption and optimizing the overall efficiency of the concrete pump. By storing and reusing energy, it diminishes the reliance on a constant power supply from the primary hydraulic system, subsequently easing the burden on the pump's engine and enhancing fuel efficiency. To summarize, the concrete pump hydraulic accumulator serves the paramount purpose of storing and releasing hydraulic energy, guaranteeing a consistent and uninterrupted flow of concrete during pumping activities. Additionally, it plays a significant role in energy efficiency and safeguarding the pump from potential harm.

- Q: What are the advantages of using ceramic components in concrete pump spare parts?

- There are several advantages of using ceramic components in concrete pump spare parts. Firstly, ceramic materials are known for their exceptional hardness and wear resistance, making them highly durable and long-lasting. This means that ceramic components in concrete pump spare parts will withstand the abrasive nature of concrete and other materials, reducing the frequency of replacements and increasing the overall lifespan of the equipment. Secondly, ceramic components offer excellent corrosion resistance, especially when compared to traditional metal parts. This is particularly important in the concrete pumping industry, as concrete contains various chemicals and substances that can cause corrosion in metal components over time. By using ceramic parts, the risk of corrosion and subsequent equipment failure is significantly reduced, leading to lower maintenance costs and improved operational efficiency. Additionally, ceramic components have excellent thermal and electrical insulation properties. This means that they can withstand high temperatures without deforming or losing their structural integrity. In concrete pumping applications, where high temperatures can be generated due to friction and pressure, using ceramic parts ensures the equipment's reliability and performance. Lastly, ceramic components are known for their lightweight nature. Compared to metal parts, ceramic components are lighter, contributing to overall weight reduction of the equipment. This not only makes it easier to transport and handle the spare parts but also reduces the strain on the equipment, ultimately improving its efficiency and reducing energy consumption. Overall, the advantages of using ceramic components in concrete pump spare parts include superior hardness, wear resistance, corrosion resistance, thermal and electrical insulation, and lightweight properties. These benefits contribute to longer equipment lifespan, reduced maintenance costs, improved reliability, and enhanced operational efficiency in the concrete pumping industry.

Send your message to us

Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords