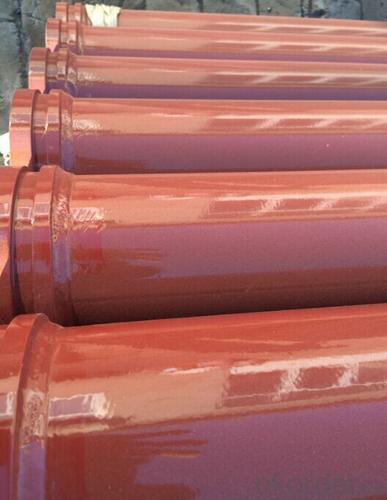

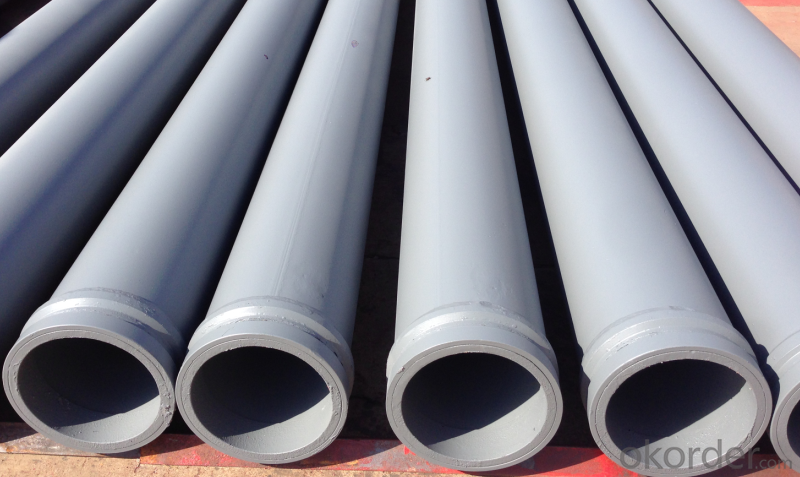

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 1MTR Thick 4.5MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.

2. Seaworthy packing or as customers’ request.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. A wide range of specifications for you.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 1m

Thickness: 4.5mm

Material: ST52

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: Are there any specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts. 1. Size and Compatibility: Ensure that the hydraulic filter or strainer you are installing is the correct size and compatible with the specific make and model of the concrete pump. Using the wrong size or incompatible filter can result in poor filtration or damage to the hydraulic system. 2. Location: The filter or strainer should be installed in a location that allows for easy access and maintenance. It should be positioned in a way that allows for proper filtration of the hydraulic fluid without obstructing the flow. 3. Mounting: The filter or strainer should be securely mounted to prevent any movement or vibration during operation. It is important to follow the manufacturer's instructions for proper mounting techniques and torque specifications. 4. Orientation: Pay attention to the recommended orientation of the filter or strainer. Some filters have specific flow direction requirements, and installing them incorrectly can affect their performance and efficiency. 5. Protection: Consider installing additional protection, such as a guard or shield, to prevent damage to the filter or strainer from external factors like debris or impacts. This can help prolong the lifespan and effectiveness of the filter. 6. Maintenance: Regularly inspect and clean the filter or strainer to ensure proper functioning. Follow the manufacturer's recommended maintenance schedule and procedures for replacement or cleaning to maintain optimal filtration efficiency. It is important to consult the manufacturer's instructions and guidelines for the specific hydraulic filter or strainer being installed, as they may have specific recommendations or requirements unique to their product.

- Q: How often should a concrete pump cleaning ball be used?

- A concrete pump cleaning ball should be used after every use of the pump to ensure proper maintenance and prevent clogs or blockages.

- Q: What are the signs of a clogged or damaged hydraulic filter?

- There are several signs that may indicate a clogged or damaged hydraulic filter. One of the most common signs is a decrease in hydraulic system performance. If you notice a decrease in the speed or power of your hydraulic equipment, it could be a result of a clogged filter restricting the flow of hydraulic fluid. Another sign is increased heat in the hydraulic system. A clogged or damaged filter can cause the system to overheat as it struggles to maintain proper fluid flow and pressure. Additionally, you may notice unusual noises coming from the hydraulic system. A clogged filter can lead to air being trapped in the system, causing it to make strange noises such as whining or grinding. Furthermore, if you see dirty or discolored hydraulic fluid, it could indicate a clogged or damaged filter. The filter is designed to remove dirt and contaminants from the fluid, so if it is unable to do so effectively, the fluid will become dirty and discolored. Lastly, if you experience frequent or recurring issues with the hydraulic system, it could be a sign of a clogged or damaged filter. The filter plays a crucial role in maintaining the overall health of the hydraulic system, so if it is not functioning properly, it can lead to other problems such as pump failure or valve blockages. It is important to regularly inspect and replace hydraulic filters to ensure the proper functioning and longevity of your hydraulic system.

- Q: What are the preventive measures for concrete pump?

- Pumping concrete should meet the requirements of pumping, and if necessary, test pump to determine the pump concrete mix ratio.

- Q: How do I maintain and clean concrete pump spare parts?

- Maintaining and cleaning concrete pump spare parts involves regular inspections, lubrication, and following proper cleaning procedures. Firstly, conduct routine checks to identify any signs of wear, damage, or loose connections. Lubricate the moving parts as recommended by the manufacturer to ensure smooth operation and prevent rust. When cleaning, use a mild detergent and water solution to remove any dirt, debris, or concrete residue. Avoid using harsh chemicals or abrasive tools that could damage the parts. It's crucial to follow the manufacturer's guidelines and consult the equipment manual for specific instructions on maintaining and cleaning concrete pump spare parts.

- Q: What are the elements of concrete pump and concrete pump truck selection?

- The construction of concrete pump truck has more adaptability and flexibility, boom height, pouring height and cloth radius is bigger, stronger adaptability to construction, in the construction should choose the high concrete pump boom. The concrete pump truck with boom length 28~36m is a large and wide range of products in the market, and about 75%. long arm concrete pump will be the main type of construction. In addition, the concrete pump truck is limited by the automobile chassis capacity. When the boom height exceeds 42m, the cost increases greatly, and it is limited by the space of the construction site, so it is rarely used.

- Q: What are the advantages of using tungsten carbide components in concrete pump spare parts?

- There are several advantages of using tungsten carbide components in concrete pump spare parts. Firstly, tungsten carbide is an extremely hard and durable material, which ensures longer lifespan and increased wear resistance of the components. This means reduced maintenance and replacement costs in the long run. Additionally, tungsten carbide has excellent corrosion resistance, making it suitable for use in harsh and corrosive environments commonly found in concrete pumping applications. Furthermore, tungsten carbide components offer superior strength and toughness, enabling them to withstand high-pressure and heavy-duty operations without compromising performance. Overall, the use of tungsten carbide in concrete pump spare parts leads to improved efficiency, reliability, and cost-effectiveness in concrete pumping operations.

- Q: What is the role of a concrete pump hopper grate pin retainer?

- The role of a concrete pump hopper grate pin retainer is to secure the grate pins in place, preventing them from dislodging or falling out during the pumping process. This helps to maintain the stability and integrity of the hopper grate, ensuring efficient and safe operation of the concrete pump.

- Q: How to judge the concrete pipeline blockage?

- Listen to the ear, there is rustling sound as normal, there is a piercing sound for the blockage

- Q: What is the second generation pumping technology of concrete pump?

- The hydraulic reversing technology is realized by reversing the hydraulic signals of the main cylinder and the small hydraulic cylinder.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 1MTR Thick 4.5MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords