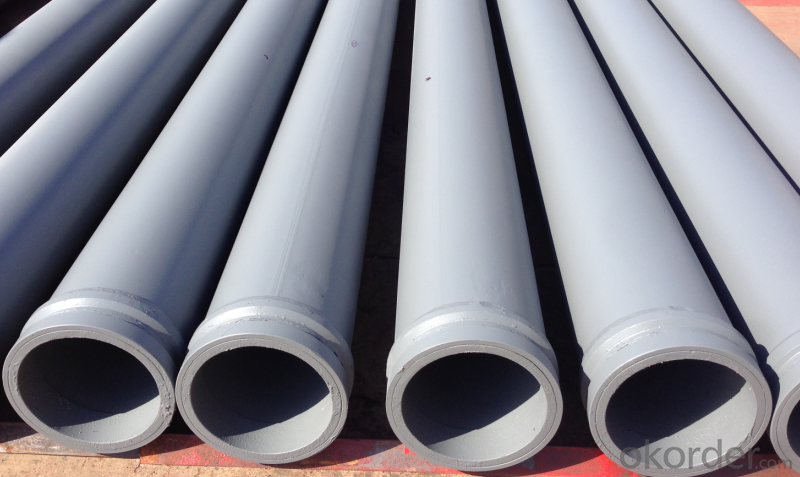

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 3MTR Thick 4.5MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

Adopt ST52 as standard material, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.

The inner side of this concrete pump pipe can undergoes heat treatment, and then the hardness can reach 63HRC.

Possess quality certification of ISO 9001:2000. Can pass CE test.

A wide range of specifications for you.

We can supply OEM service and can also produce according to your requirements./ OEM service available.

Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 3m

Thickness: 4.5mm

Material: ST52

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: How can one differentiate between genuine and counterfeit concrete pump spare parts?

- Differentiating between genuine and counterfeit concrete pump spare parts can pose a challenge, but there are several methods to ensure the authenticity of your purchase. Consider the following strategies: 1. Manufacturer Research: Begin by thoroughly researching the manufacturer of the concrete pump spare parts. Look for reputable, well-established companies with a proven track record. Analyze their industry standing, read customer reviews, and examine their website. Genuine manufacturers typically have a strong online presence and provide detailed product information. 2. Supplier Verification: When purchasing spare parts, it is crucial to select a reliable and authorized supplier. Ensure the supplier has a good reputation in the industry and a long-standing presence. Authorized distributors often have direct relationships with manufacturers and can provide authentic parts. 3. Inspection of Product Packaging: Genuine concrete pump spare parts typically have specific packaging that includes branding, logos, and detailed product information. Counterfeit products may have inferior packaging quality, misspellings, incorrect logos, or inconsistent color schemes. Carefully examine the packaging to determine its authenticity. 4. Evaluation of Product Quality and Finish: Counterfeit parts are often made from low-quality materials and lack the precision and finish of genuine parts. Inspect the spare parts for signs of poor workmanship, rough edges, or uneven surfaces. Genuine parts are typically well-crafted and undergo strict quality control measures. 5. Price Comparison: Exercise caution when encountering significantly lower prices for spare parts, as this may indicate counterfeit products. Counterfeiters often sell their goods at lower prices to attract customers, but the quality and performance may be compromised. Compare prices with other suppliers to ensure they fall within the expected range. 6. Seek Expert Advice: If you are unsure about the authenticity of concrete pump spare parts, consult industry experts or experienced professionals. They can assist you in identifying genuine components and making informed decisions. 7. Request Certifications and Documentation: Genuine manufacturers provide certifications and documentation, such as ISO certifications or test reports, to validate the quality and authenticity of their products. Ask the supplier for these documents and verify their legitimacy with the manufacturer if necessary. Remember, purchasing genuine concrete pump spare parts is crucial for the safety and efficiency of your equipment. By following these steps and exercising caution, you can minimize the risk of purchasing counterfeit components and ensure the longevity and reliable performance of your concrete pump.

- Q: What is the name of the pump for concrete transportation?

- Concrete pump truck is modified on truck chassis. It is equipped with motion and power transmission device, pumping and mixing device, cloth device and other auxiliary devices on the chassis.

- Q: How does a hydraulic oil cooler maintain optimal temperature in a concrete pump?

- In order to maintain the ideal temperature in a concrete pump and prevent potential issues, it is crucial to have a hydraulic oil cooler. The hydraulic system of a concrete pump is constantly exposed to high pressure and heavy loads, causing the oil within the system to heat up quickly. If the oil temperature exceeds the recommended range, it can lead to decreased efficiency, increased wear and tear, and even system failure. To avoid these problems, a hydraulic oil cooler is installed in the concrete pump. This cooler utilizes a heat exchanger to transfer the excess heat from the hydraulic oil to the surrounding air or another cooling medium, such as water or a refrigerant. This process effectively lowers the temperature of the hydraulic oil, keeping it within the optimal range for operation. The hydraulic oil cooler typically consists of fins or tubes that allow the hot oil to flow through. These fins or tubes increase the surface area of contact between the oil and the cooling medium, enabling efficient heat transfer. In some cases, a fan or pump may be used to enhance the airflow or flow of the cooling medium, further improving the cooling process. By maintaining the hydraulic oil at the ideal temperature, the hydraulic oil cooler ensures that the concrete pump operates at its highest level of performance. This not only increases the overall efficiency and productivity of the pump but also extends the lifespan of critical components. Additionally, by preventing overheating, the hydraulic oil cooler helps to minimize the risk of unexpected downtime and costly repairs. In conclusion, a hydraulic oil cooler is an essential component in a concrete pump as it effectively dissipates excessive heat from the hydraulic oil, ensuring optimal temperature and contributing to the overall productivity and reliability of the pump.

- Q: What is the purpose of a concrete pump agitator motor?

- The objective of a concrete pump agitator motor is to guarantee the uniformity and excellence of the concrete mixture being transported. Its role involves ensuring that the concrete mixture remains well-blended and prevents any settling or separation during the pumping procedure. The agitator motor aids in maintaining a consistent and homogeneous mixture, which is essential for achieving sturdy and long-lasting concrete structures. Through continuous agitation of the concrete inside the pump, the motor assists in averting any obstruction or congestion that may potentially disrupt the pumping operation. In general, the purpose of a concrete pump agitator motor is to optimize the efficiency and effectiveness of the concrete pumping process, ultimately leading to improved construction outcomes.

- Q: Can a concrete pump wear plate be repaired or does it need to be replaced entirely?

- In certain situations, a concrete pump wear plate may require repair or complete replacement. The determination of whether to repair or replace the wear plate depends on the extent of the damage and the overall condition of the plate. In the case of minor damages such as small cracks, dents, or worn out areas, suitable techniques can often be employed for repair. For instance, small cracks can be welded or filled with an appropriate epoxy or filler material. Similarly, dents or worn out areas can be filled and smoothed to restore the plate's functionality. However, if the wear plate has sustained significant damage, such as extensive cracks, severe corrosion, or large holes, it may be more advisable to replace the plate entirely. This is due to the potential compromise in the structural integrity and effectiveness of the wear plate if extensive damage is repaired. Optimal performance and safety of the concrete pump can be ensured by replacing the wear plate in these cases. Careful assessment of the wear plate's condition is crucial before deciding to repair or replace it. Seeking guidance from experts or professionals knowledgeable in concrete pump maintenance can provide valuable insights in making the appropriate decision. Additionally, regular maintenance and inspection of the wear plate can help detect potential issues early on, enabling timely repairs or replacements to prevent further damage and ensure the efficient operation of the concrete pump.

- Q: How to diagnose the blockage in the inlet of concrete pump?

- Make the pump reverse running to destroy the caking, return the concrete to the hopper, stir it again, and then pump it forward

- Q: What are the different sizes of concrete pump pipes available?

- The sizes of concrete pump pipes available vary depending on the specific needs and requirements of the construction project. Typically, concrete pump pipes come in sizes ranging from 2 inches to 6 inches in diameter. The most commonly used sizes are 2 inches, 3 inches, 4 inches, and 5 inches. The choice of pipe size depends on factors such as the volume and pressure of the concrete being pumped, the distance the concrete needs to travel, and the type of equipment being used. Smaller diameter pipes are suitable for shorter distances and lower volumes of concrete, while larger diameter pipes are used for longer distances and higher volumes. It is important to select the appropriate pipe size to ensure efficient and safe concrete pumping. Using the correct size of pipe helps to minimize pressure loss, maintain a consistent flow rate, and prevent blockages or clogs in the system. Consulting with a concrete pumping professional or engineer is recommended to determine the most suitable pipe size for a specific construction project.

- Q: How can a malfunctioning hydraulic motor affect the pumping process?

- A malfunctioning hydraulic motor can have various negative effects on the pumping process. Firstly, it can result in a decrease in pumping efficiency. The hydraulic motor is responsible for converting the hydraulic energy into mechanical energy, which drives the pumping mechanism. If the motor is malfunctioning, it may not be able to generate enough power to operate the pumping system effectively, leading to a decrease in the volume or pressure of the pumped fluid. Additionally, a malfunctioning hydraulic motor can cause an increase in energy consumption. Inefficient or faulty motor operation can lead to higher energy requirements to maintain the desired pumping rate. This increased energy consumption can result in higher operating costs and reduced overall system performance. Furthermore, a malfunctioning hydraulic motor can lead to irregular pumping or complete pump failure. If the motor is not functioning properly, it may result in intermittent or inconsistent pumping, causing fluctuations in the flow rate or pressure of the pumped fluid. In extreme cases, the motor may completely stop working, leading to a total loss of pumping functionality. Moreover, a malfunctioning hydraulic motor can cause increased wear and tear on the entire pumping system. The motor's improper operation can create excessive vibration or heat, leading to premature failure of other components such as seals, bearings, or pistons. This can result in frequent maintenance or repair requirements, leading to increased downtime and costs. In summary, a malfunctioning hydraulic motor can have significant negative impacts on the pumping process, including decreased efficiency, increased energy consumption, irregular pumping or complete pump failure, and increased wear and tear on the system. It is crucial to regularly inspect and maintain hydraulic motors to ensure their proper functioning and avoid potential issues that may disrupt the pumping process.

- Q: How do I troubleshoot issues related to concrete pump spare parts control systems?

- To troubleshoot issues related to concrete pump spare parts control systems, you can follow these steps: 1. Start by checking the power supply and connections to ensure there are no loose or damaged wires. 2. Verify that the control system is properly calibrated and programmed according to the manufacturer's instructions. 3. Inspect the control panel for any visible signs of damage, such as burnt components or water ingress. 4. Use a multimeter to test the voltage and continuity of different control system components, such as sensors, switches, and relays. 5. Consult the system's user manual or contact the manufacturer for any specific troubleshooting steps or error code interpretations. 6. If the issue persists, consider contacting a professional technician or the manufacturer's customer support for further assistance.

- Q: How do I ensure the reliability of concrete pump spare parts in critical applications?

- To ensure the reliability of concrete pump spare parts in critical applications, there are several steps you can take: 1. Choose a reputable supplier: Research and select a trusted supplier known for providing high-quality concrete pump spare parts. Look for suppliers with a strong track record, positive customer reviews, and certifications that demonstrate their commitment to quality and reliability. 2. Verify product specifications and certifications: Before purchasing any spare parts, carefully review the product specifications and certifications. Ensure that the parts meet the required standards and have undergone rigorous testing to guarantee their reliability in critical applications. 3. Conduct regular maintenance and inspections: Implement a comprehensive maintenance and inspection schedule for your concrete pump and its spare parts. Regularly check for signs of wear, damage, or malfunction. Replace any parts that show signs of deterioration or that no longer meet the required specifications. 4. Use genuine spare parts: Always opt for genuine spare parts that are specifically designed for your concrete pump model. Genuine parts are manufactured to the highest standards and are more likely to provide reliable performance in critical applications compared to generic or counterfeit alternatives. 5. Keep an inventory of critical spare parts: Identify the most critical spare parts that are prone to failure or wear and keep an inventory of these parts on hand. This will minimize downtime in case of unexpected failures and ensure that you can quickly replace any faulty components. 6. Train and educate operators: Provide thorough training to your concrete pump operators on proper handling and maintenance of spare parts. Educate them on the importance of following manufacturer guidelines and best practices to maximize the reliability and longevity of the equipment. 7. Prioritize safety: Safety should always be a top priority in critical applications. Ensure that the spare parts you use are compliant with safety regulations and standards. Regularly assess and update safety protocols to minimize the risk of accidents or equipment failure. By following these steps, you can enhance the reliability of concrete pump spare parts in critical applications, reducing the likelihood of downtime and ensuring the smooth operation of your equipment.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 3MTR Thick 4.5MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords