Concrete pump spare parts concrete pump boom pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Data |

Material | 45MN2/20#/16MN/Q345 etc |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

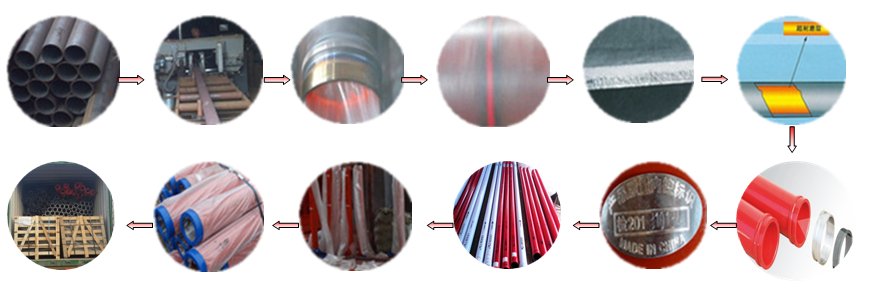

Process | High temperature quenching |

HRC | 65 |

Product Specifications Model Description:

| Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Maxture work press |

| Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

| Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

| Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

| Diamondwear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

| W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

| W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

| GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

| GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

Our services:

1, In case of quality problem the company provide free replacement

2, Provide technical support for free

3, Provide consumers with regular visits

4, Ensure the supply of ancillary parts

5, The company passed the ISO9000 certification, the product through 3 c certification in full compliance with national standards

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Why choose us:

1. We are a comprehensive manufacturing and trading company.

2. Our company is one of the biggest manufacturing and trading companies in China.

3. We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

4. We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

5. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: The inside diameter of my bearing is 12mm. Now I want to work on a round shaft so that it can fit into the bearing hole, and there is almost no pulsation in the radial direction. Then how should the shaft be designed? The axle diameter is just 12mm Or a little smaller than 12mm? How much smaller?Thank you for your answer, my bearings are NSK, the accuracy level is P4, diameter 12, outer diameter 32, then how should I design the shaft? And how to design the fixed seat (sleeve, bearing) of the bearing?

- Your bearing is 6201, according to the light load (so small things will not be used in place of large load), shaft to rotate, so after the query "mechanical design manual" bearing with the content, size and tolerance can have shaft should be 12h5 (difference 0, under -0.008). Bearing seat to go to the market, the store owner knows.

- Q: What exactly is mechanical design?

- the various parts of the material and shape size and lubrication methods for design, analysis and calculation and put it into specific description as a basis for the manufacturing process.

- Q: The strength criterion of mechanical parts design is briefly introduced

- 1, the strength criterion requires that the working stress of the mechanical parts should not exceed allowable stress [Sigma]. The formula is typical: (3-16) lim - ultimate stress of brittle materials by static stress on the ultimate strength, the static stress of plastic materials, the yield limit of zero stress the fatigue limit. S - Safety factor. 2. stiffness criteria mechanical components are subject to elastic deformation when subjected to load. Stiffness is the ability to resist deformation of materials, mechanical parts, or structures subjected to external forces. The stiffness of the material is measured by the external force required to produce the unit deformation. The stiffness of a mechanical part depends on its modulus of elasticity, E or shear modulus, G, geometry and size, and the form of external forces. It is an important work in mechanical design to analyze the rigidity of mechanical parts. For some parts that need to be strictly deformed (such as wings, machine tools, spindles, etc.), stiffness analysis is necessary to control the deformation. We also need to control the stiffness of the parts to prevent vibration or instability. In addition, a spring, such as a spring, must be used to control its stiffness to a reasonable value to ensure its specific function. The stiffness criterion is that the elastic deformation of a component subjected to load is not greater than the allowable elastic deformation. The expression of the stiffness criterion is (3 - 17) y is an elastic deformation quantity, such as deflection, longitudinal elongation (shortening): [y] is the corresponding allowable elastic deformation. The elastic deformation of a part can be obtained by theoretical calculation or by experiment. The allowable deformation depends on the use of the part, and is determined by theoretical analysis or experience.

- Q: I designed a great bike with my own mechanical design software. Now I keep it in the computer. What I want to ask isHow do you get these components of the same size, give them the money in the factory, and then make them as planned? Give me a clue, such as magnesium alloy, carbon steel, and so on

- As long as you design the materials used in the car, the market is good to buy, it is easy to find people, like magnesium alloy, I guess a little difficult

- Q: Machining process design of shaft parts is required

- 7. precision cars8. mill excircle9. milling keyway10. deburring11. inspection12. cleaning13 warehousing

- Q: What are the main principles of mechanical principles and mechanical parts design?

- 4. weight requirements, often in the hands of the parts required lightweight, in the case of mechanical strength to meet the choice of small proportion of materials;5. service life requirements are temporary or long-term use, intends to use a year or 10 years?6., the influence of environmental temperature, environmental temperature changes will affect the expansion of parts;

- Q: What software is best for designing mechanical parts?

- Our private units in general like to use CAXA electronic chart, get started quickly, simple and easy to use.The joint venture requires the use of AutoCAD, powerful, cumbersome operation, can do complex three-dimensional map.

- Q: The basic idea of mechanical parts design is briefly introduced

- 1, according to the requirements and conditions, determine the type of parts2, determine the parts load, select materials, formulate parts work capacity, calculate the key size;

- Q: Good mechanical design or good mechanical manufacturing?

- mold design is designed, is relatively easy. These industries are good, see what you want to develop it.

- Q: Mechanical design of various parts of the hardness value of how to determine?.

- Give your reference value, heat treatment is most hard, probably 65HRC, this is the limitAnd 45 steel without heat treatment, only about 10When you design, the hardness does not require a material can be set, there are hardness requirements, then the technical requirements of hardness

Send your message to us

Concrete pump spare parts concrete pump boom pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords