concrete boom pipe in sany concrete pump spare parts

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Data |

Material | 45MN2/20#/16MN/Q345 etc |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

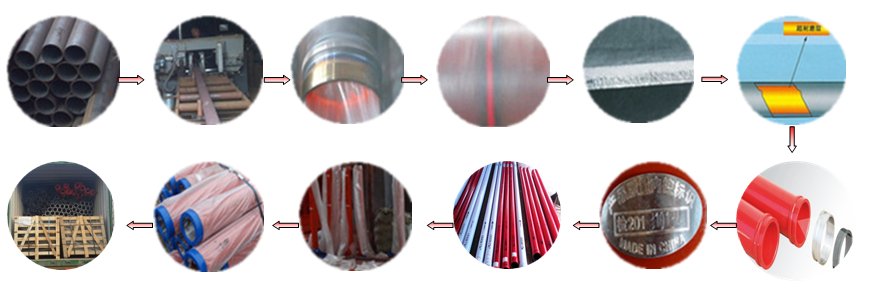

Process | High temperature quenching |

HRC | 65 |

Product Specifications Model Description:

| Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Maxture work press |

| Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

| Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

| Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

| Diamondwear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

| W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

| W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

| GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

| GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

Our services:

1, In case of quality problem the company provide free replacement

2, Provide technical support for free

3, Provide consumers with regular visits

4, Ensure the supply of ancillary parts

5, The company passed the ISO9000 certification, the product through 3 c certification in full compliance with national standards

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Why choose us:

1. We are a comprehensive manufacturing and trading company.

2. Our company is one of the biggest manufacturing and trading companies in China.

3. We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

4. We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

5. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: Who knows what the design criteria for machine parts are, and how they are designed?

- 5. life standards, in order to ensure that the machine in a certain life span of normal work, in the design of mechanical parts, it is necessary to request the life of mechanical parts. It should be explained that parts can be replaced during the life of the machine, that is, the life of some mechanical parts is shorter than the life of the machine. The life of mechanical parts is mainly affected by fatigue, wear and corrosion of materials. In order to avoid failure caused by parts fatigue, such as fatigue fracture, fatigue strength should be calculated according to the fatigue limit corresponding to the life of mechanical parts. That is to say, according to the requirements of life and the specific speed of parts, according to formula (3-6), the fatigue limit is calculated when the stress cycle number is N. Then the strength condition is calculated and the fatigue strength is calculated. When the fatigue strength is satisfied, the stress cycle times of the mechanical parts can be guaranteed before the damage. Wear is usually unavoidable. Under certain conditions, corrosion is inevitable, such as structural members of bridges, corrosion of buried steel pipelines, etc.. In the design, mainly to ensure the mechanical parts in life, not excessive wear and corrosion. The mechanism of wear is still fully mastered, and there are many factors affecting wear. Generally, the wear resistance of friction pairs is improved according to the tribological design principle. The main measures are as follows: reasonable selection of friction pairs, reasonable choice of lubricant and additives, and control of the working conditions of friction pairs, such as pressure, sliding speed and temperature rise. So far, there is no practical and effective method for calculating corrosion life

- Q: Force calculation is in the component diagram, the size of the component is obtained by force, and if you don't draw the parts first, how do you draw the general plan?How do you calculate the force of a part if you draw the part diagram first and don't know the size relation between the parts?

- First draw a diagram, determine the location of each part, then draw the parts drawing, and finally the general drawing

- Q: What are the basic criteria for the design of mechanical parts?

- 2. reliable and effective safety protectionAny job of dismantling an old machine is in such a danger that the risk of environmental conditions and the performance of the operator in a dynamic combination is greater when it comes to dismantling the parts of an old machine. As long as there is danger, even if the operator has good technical training and safety education, there are perfect procedures, but also can not completely avoid the risk of mechanical injury accidents. Therefore, a reliable material barrier must be established, that is, to install one or more protective devices, safety devices or other safety measures that are specifically designed to protect the safety of persons. When the equipment or operation of some aspects of the problem, relying on the mechanical safety of their own technical measures to avoid accidents, and ensure the safety of personnel and equipment. Equipment with high risk or high accident rate must be equipped with safety protection device.

- Q: Machining process design of shaft parts is required

- 7. precision cars8. mill excircle9. milling keyway10. deburring11. inspection12. cleaning13 warehousing

- Q: How to design the power assisted robot, mechanical structure and pneumatic part, please point out, thank you!

- Professional production, you can go to understand, draw on for reference

- Q: What are the main functions of CAE software commonly used in the design of mechanical products or parts?

- Finite element analysis, structural motion analysis, interference checking, dimensional chain analysis.

- Q: I'm going to learn 3D design. I used to just CAD.Excuse me, is it good to learn PRO-E or SOLIDWORK?I mainly used in product design (such as sheet metal parts, machining parts and plastic parts, etc.) is used to design the mould.Also, you can download the best Chinese version of these two software from the Internet, please ask friends about the locationUrgently...

- These two can, there is a director, according to the domestic general situation, usually PROE use more, exchange more convenient, as long as there is a three-dimensional software with skilled, no matter that can be.

- Q: Are there any standards or specifications for the design of parts list in mechanical design?

- Each company's specifications are not the same, but the general processing parts must have part name, parts drawing number, quantity, material / heat treatment methods (surface treatment methods), remarks, etc.. If purchased, it includes name, model, brand, requirement, remark and so on

- Q: What do engineers need to learn from mechanical design as an electronic hardware engineer?

- It is suggested that the first learn the "foundation" of precision machinery design, then study the "Electronic Electrical Engineering", if it is possible to learn the "modern metal material technology", because accurate small parts, put forward higher requirements on the properties of the materials used.

- Q: Mechanical design of various parts of the hardness value of how to determine?.

- Give your reference value, heat treatment is most hard, probably 65HRC, this is the limitAnd 45 steel without heat treatment, only about 10When you design, the hardness does not require a material can be set, there are hardness requirements, then the technical requirements of hardness

Send your message to us

concrete boom pipe in sany concrete pump spare parts

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords