concrete pipe of sany concrete pump spare parts

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Data |

Material | 45MN2/20#/16MN/Q345 etc |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

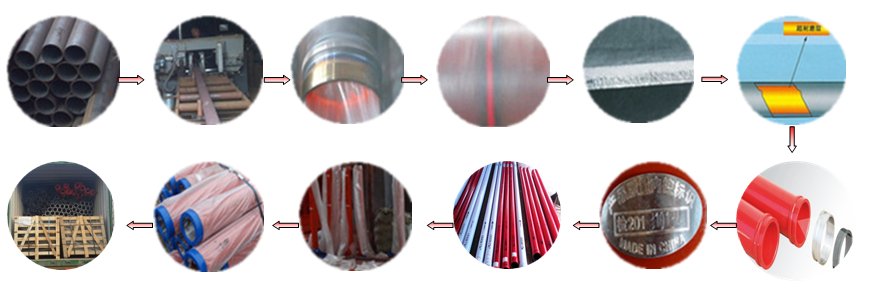

Process | High temperature quenching |

HRC | 65 |

Product Specifications Model Description:

| Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Maxture work press |

| Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

| Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

| Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

| Diamondwear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

| W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

| W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

| GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

| GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

Our services:

1, In case of quality problem the company provide free replacement

2, Provide technical support for free

3, Provide consumers with regular visits

4, Ensure the supply of ancillary parts

5, The company passed the ISO9000 certification, the product through 3 c certification in full compliance with national standards

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Why choose us:

1. We are a comprehensive manufacturing and trading company.

2. Our company is one of the biggest manufacturing and trading companies in China.

3. We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

4. We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

5. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: In the design of large machinery, it is to design the parts first, the assembly drawings as well

- In the design of large machinery, it is to design the parts first, the assembly drawings as well

- Q: An analog aircraft equipment, in the middle of the two electric cylinder to provide equipment up and down force, two electric cylinders are together and synchronized up and down movement (should be an electric cylinder support force is not enough?) I understand so, so it can only provide the upper and lower forces, the front and left of the three directions, each one of the black rod-shaped structure is how to provide the equipment about deviation, upward and downward deflection of the force? At the same time, how to make these forces achieve controllable effect, complete flight simulation?If cannot send the video address to BIRDLY Baidu flight simulator with complete video, can be seen with me after the detailed explanation, there can also be additional points I'm curious about design of the structure, the answer may take some time and I say that with QQ

- Mechanical design, the analysis of the role of the entity rhythm, WO wrote two articles, which can be referred to you.

- Q: Does the SolidWorks mechanical design engineer paint parts individually or draw parts in an assembly?

- Either way, in actual work, the two approaches may alternate.If you do is mechanism design, may be other assembly references, can consider each part separately draw, so in the future by other assembly references when good maintenance, no loss of reference.If you do need to consider other parts of the related parts, such as the appearance of the skin, a variety of sports organizations, etc., can be considered to create parts in the assembly, can avoid some mistakes when combined with other parts. However, it is still recommended that you minimize the external reference in the assembly and make the key features that require external reference, and that the rest of the features are still done in an independent part manner.

- Q: Who knows what the design criteria for machine parts are, and how they are designed?

- 5. life standards, in order to ensure that the machine in a certain life span of normal work, in the design of mechanical parts, it is necessary to request the life of mechanical parts. It should be explained that parts can be replaced during the life of the machine, that is, the life of some mechanical parts is shorter than the life of the machine. The life of mechanical parts is mainly affected by fatigue, wear and corrosion of materials. In order to avoid failure caused by parts fatigue, such as fatigue fracture, fatigue strength should be calculated according to the fatigue limit corresponding to the life of mechanical parts. That is to say, according to the requirements of life and the specific speed of parts, according to formula (3-6), the fatigue limit is calculated when the stress cycle number is N. Then the strength condition is calculated and the fatigue strength is calculated. When the fatigue strength is satisfied, the stress cycle times of the mechanical parts can be guaranteed before the damage. Wear is usually unavoidable. Under certain conditions, corrosion is inevitable, such as structural members of bridges, corrosion of buried steel pipelines, etc.. In the design, mainly to ensure the mechanical parts in life, not excessive wear and corrosion. The mechanism of wear is still fully mastered, and there are many factors affecting wear. Generally, the wear resistance of friction pairs is improved according to the tribological design principle. The main measures are as follows: reasonable selection of friction pairs, reasonable choice of lubricant and additives, and control of the working conditions of friction pairs, such as pressure, sliding speed and temperature rise. So far, there is no practical and effective method for calculating corrosion life

- Q: What is the significance of using this "three changes" in mechanical design?

- Standardization is the design of things, do not have any significance of the difference, unified, become standard, is a reference, there are similar can rely on a standard. Like analog to digital conversion, the analog is transformed into a digital quantity that becomes discontinuous, but always satisfactory.Serialization is a product divided into different specifications, used in different needs, to find the corresponding level. It's like a dress. Tall, medium, and short people have to wear it. Products of the same function, the poor, the middle class and the rich, have their own affordable specifications.General purpose is interchangeable, easy to mass production, easy maintenance, once designed, can be used directly.The significance of standardization is to reduce unnecessary diversity.The significance of serialization is to form a routine, along the way, to sort out a category.The significance of generalization lies in the fact that similar situations are used directly and copied.

- Q: How to write the machining process design of machine parts?

- The so-called processing technology, that is: the processing of each process, the processing required to what extent?. If the text is not clear, you can draw the technical drawings to illustrate.

- Q: their own materials, hope that the older generation can be under the guidance of the younger brother, brother, thank you very much

- Knowledge of material knowledge of machine parts is usually required:1., first learn some basic knowledge, such as material mechanics, theoretical mechanics, metal materials, heat treatment, metallographic, hot processing, cold processing.2. then learn more about your work unit product. Technical data of main components, performances, requirements and common materials.3., online access to the same or similar industry related information.

- Q: The basic idea of mechanical parts design is briefly introduced

- 1, according to the requirements and conditions, determine the type of parts2, determine the parts load, select materials, formulate parts work capacity, calculate the key size;

- Q: Are there any standards or specifications for the design of parts list in mechanical design?

- Each company's specifications are not the same, but the general processing parts must have part name, parts drawing number, quantity, material / heat treatment methods (surface treatment methods), remarks, etc.. If purchased, it includes name, model, brand, requirement, remark and so on

- Q: Mechanical design of various parts of the hardness value of how to determine?.

- In mechanical design, you need to determine the material, strength, and wear requirements of other parts at relatively moving locations so that you can determine how to heat the parts and achieve the best hardnessIf you are testing mature products both at home and abroad, you only need to have hardness and test materials for each part

Send your message to us

concrete pipe of sany concrete pump spare parts

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords