Wear Resistant Concrete Pump Delivery Pipe Elbow/Pipe Bend

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Material | Specification | Weight | Common life time | Life tine for two end parts | Max work pressure |

Normal bend | ZG40Mn2 | DN125R27590° | 16kgs | 6000-8000m³ | 1000-3000m³ | 126 bar |

Wear-resistant bend | Mn13-4 | DN125R27590° | 16.5kgs | 20000-25000m³ | 2000-7000m³ | 132 bar |

Twin wall bend | Cr20NiCu1Mo+G20 | DN125R27590° | 15kgs | 60000-80000m³ | 20000-30000m³ | 91 bar |

Twin wall bend | GX350+G20 | DN125R27590° | 15kgs | 80000-150000m³ | 40000-50000m³ | 98 bar |

Product Specifications Model:

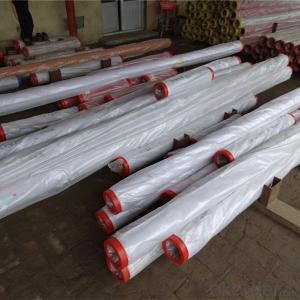

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Why choose us:

1. We are a comprehensive manufacturing and trading company.

2. Our company is one of the biggest manufacturing and trading companies in China.

3. We have been specialized in producing concrete pump spare parts for 10 years and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

4. We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

5. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: 3D MAX must set motion for each object. Is there a 3D mechanical design software that can simulate the mechanical movement of the parts?As long as the specified object is motor, coupling, chain, gear, into the simulation, the three-dimensional map of the motor shaft will rotate, and drives the coupling, keys, gear for the corresponding movement, rather like 3D Max that is the true state of motion to each object design movement performance of this machine combination?

- SOLIDWORKSBut it is also necessary to develop the law of motion relative to 3DMAX, but your modeling is a problem,Can you NURBS? SOLIDWORKS does not support polygon modelingIf I import the file, there's only line segments. I haven't found a better wayIt's better to continue using 3DMAX

- Q: In the design of large machinery, it is to design the parts first, the assembly drawings as well

- The design stage to do assembly structure. According to the structure design of parts and related calculation. The choice of materials and structures suitable. The original painting is the first climbing board assembly, and then split the parts of the map.

- Q: What are the basic requirements for the design of mechanical parts?

- 2. stiffnessThe elastic deformation of a component at work does not exceed the allowable limit. This is called the stiffness requirement. Obviously, only when the elastic deformation is too large to affect the working performance of the machine, it is necessary to meet this requirement. For this kind of parts, besides the strength calculation, the stiffness calculation must be done.

- Q: Force calculation is in the component diagram, the size of the component is obtained by force, and if you don't draw the parts first, how do you draw the general plan?How do you calculate the force of a part if you draw the part diagram first and don't know the size relation between the parts?

- First draw a diagram, determine the location of each part, then draw the parts drawing, and finally the general drawing

- Q: What are the basic criteria for the design of mechanical parts?

- 2. reliable and effective safety protectionAny job of dismantling an old machine is in such a danger that the risk of environmental conditions and the performance of the operator in a dynamic combination is greater when it comes to dismantling the parts of an old machine. As long as there is danger, even if the operator has good technical training and safety education, there are perfect procedures, but also can not completely avoid the risk of mechanical injury accidents. Therefore, a reliable material barrier must be established, that is, to install one or more protective devices, safety devices or other safety measures that are specifically designed to protect the safety of persons. When the equipment or operation of some aspects of the problem, relying on the mechanical safety of their own technical measures to avoid accidents, and ensure the safety of personnel and equipment. Equipment with high risk or high accident rate must be equipped with safety protection device.

- Q: What are the key factors in designing mechanical parts?

- 1- reliability. For example, the design of a transmission shaft, to consider whether the uniform load or impact load, axial load or radial load or both, or combined force. In general, even small loads can be fitted with clearance or transition fit, and tolerances can be enlarged so that processing costs are low. For high speed or large load or impact loads, interference fit should be used, such as flywheel shaft of diesel engine.

- Q: In the design of machine parts, how to choose the matching of bearings, what should be paid attention to when assembling?

- Bearings are purchased parts, shaft and bearing inner ring with the base hole selection, as for the flexibility of the match, depending on the use of requirements, assembly, of course, is to be installed smoothly. The bearing outer ring is matched with the box body, and the base shaft system is matched

- Q: Why do the design of mechanical parts (flanges and elbows) be based on the yield limit?

- Hello friends, usually to do the experiment to the material ontology; have tensile, bending, impact, flattening, flaring, cyclamic, normal temperature test 20 degrees Celsius, is 20 degrees Celsius, minus 20 degrees Celsius, the test to the material, to be determined after completion of the test material meets the design requirements. Is the so-called (to yield limit for design basis?)

- Q: What is the design procedure of mechanical parts urgently ah?!

- 5. assembly and parts diagram design. According to the structure and size of parts assembly sketches to determine the complete assembly and parts diagram design. (according to the plan to determine the main dimensions, structure design, parts drawing, sorting out the map) four, as the case with technical documentation requirements, design and coding machine calculation manual, manual, standard parts list, purchased parts list, etc. in the conditions of acceptance in the design process, such as a link the problem is feasible or not, need to return to revise the previous design, until the problem is solved. Sometimes, for this reason, even the whole project has to be knocked over. Therefore, the mechanical design process is an iterative process. (standard and outsourcing parts arrangement, specification preparation, acceptance documents

- Q: Before listening to the teacher mentioned that, when the design of components, we should take into account the actual processing capacity of the factory, and some look very simple things, the factory is unable to process! I want to know what the reason is!!!

- Because people are generally from the book, really have actual working experience is not much, you said a few people can personally design processing, now has several high diploma and technical school students in the first 5 years of the stem! So according to processing technology, sometimes do things, such as organic glass with oil and gas drilling is not only different from the design process is not, few people will know!

Send your message to us

Wear Resistant Concrete Pump Delivery Pipe Elbow/Pipe Bend

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords