DN125 Concrete Pump Elbow For Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Material | Specification | Weight | Common life time | Life tine for two end parts | Max work pressure |

Normal bend | ZG40Mn2 | DN125R27590° | 16kgs | 6000-8000m³ | 1000-3000m³ | 126 bar |

Wear-resistant bend | Mn13-4 | DN125R27590° | 16.5kgs | 20000-25000m³ | 2000-7000m³ | 132 bar |

Twin wall bend | Cr20NiCu1Mo+G20 | DN125R27590° | 15kgs | 60000-80000m³ | 20000-30000m³ | 91 bar |

Twin wall bend | GX350+G20 | DN125R27590° | 15kgs | 80000-150000m³ | 40000-50000m³ | 98 bar |

Product Specifications Model:

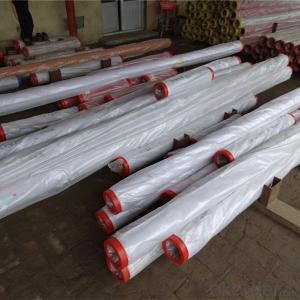

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Why choose us:

1. We are a comprehensive manufacturing and trading company.

2. Our company is one of the biggest manufacturing and trading companies in China.

3. We have been specialized in producing concrete pump spare parts for 10 years and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

4. We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

5. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: The inside diameter of my bearing is 12mm. Now I want to work on a round shaft so that it can fit into the bearing hole, and there is almost no pulsation in the radial direction. Then how should the shaft be designed? The axle diameter is just 12mm Or a little smaller than 12mm? How much smaller?Thank you for your answer, my bearings are NSK, the accuracy level is P4, diameter 12, outer diameter 32, then how should I design the shaft? And how to design the fixed seat (sleeve, bearing) of the bearing?

- Your bearing is 6201, according to the light load (so small things will not be used in place of large load), shaft to rotate, so after the query "mechanical design manual" bearing with the content, size and tolerance can have shaft should be 12h5 (difference 0, under -0.008). Bearing seat to go to the market, the store owner knows.

- Q: is it the first overall drawing, or first out parts drawings, and then assembly?

- Personal habits ~ ~ general circumstances, the first overall map, and then parts map ~!

- Q: 3D MAX must set motion for each object. Is there a 3D mechanical design software that can simulate the mechanical movement of the parts?As long as the specified object is motor, coupling, chain, gear, into the simulation, the three-dimensional map of the motor shaft will rotate, and drives the coupling, keys, gear for the corresponding movement, rather like 3D Max that is the true state of motion to each object design movement performance of this machine combination?

- SOLIDWORKSBut it is also necessary to develop the law of motion relative to 3DMAX, but your modeling is a problem,Can you NURBS? SOLIDWORKS does not support polygon modelingIf I import the file, there's only line segments. I haven't found a better wayIt's better to continue using 3DMAX

- Q: What are the main functions of CAE software commonly used in the design of mechanical products or parts?

- Finite element analysis, structural motion analysis, interference checking, dimensional chain analysis.

- Q: How does the Auto CAD menu bar do not have the "mechanical parts design" command?

- Install or load other tools without having them

- Q: What are the main principles of mechanical principles and mechanical parts design?

- 7. part surface quality requirements and corrosion protection requirements;8. cost factors;......There are many other factors.

- Q: Mechanical design practice course, let students do something

- this process appears simple, it is a complex process, such as simple and fitter tools: drill and tapping, need to work in the process of careful experience that is absolutely useless empty talk, feed on illusions. No matter what other enterprises, you have to come up with real technical ability.

- Q: their own materials, hope that the older generation can be under the guidance of the younger brother, brother, thank you very much

- Knowledge of material knowledge of machine parts is usually required:1., first learn some basic knowledge, such as material mechanics, theoretical mechanics, metal materials, heat treatment, metallographic, hot processing, cold processing.2. then learn more about your work unit product. Technical data of main components, performances, requirements and common materials.3., online access to the same or similar industry related information.

- Q: Good mechanical design or good mechanical manufacturing?

- The range of mechanical design and manufacturing involves relatively wide, including both mechanical manufacturing and automation;

- Q: Mechanical design of various parts of the hardness value of how to determine?.

- In mechanical design, you need to determine the material, strength, and wear requirements of other parts at relatively moving locations so that you can determine how to heat the parts and achieve the best hardnessIf you are testing mature products both at home and abroad, you only need to have hardness and test materials for each part

Send your message to us

DN125 Concrete Pump Elbow For Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches