Concrete Pump Spare Parts 45Mn2 Boom Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Pump Spare Parts 45Mn2 Boom Pipe

1. Structure of Concrete Pump Spare Parts 45Mn2 Boom Pipe:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

2. Main Features of Concrete Pump Spare Parts 45Mn2 Boom Pipe:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

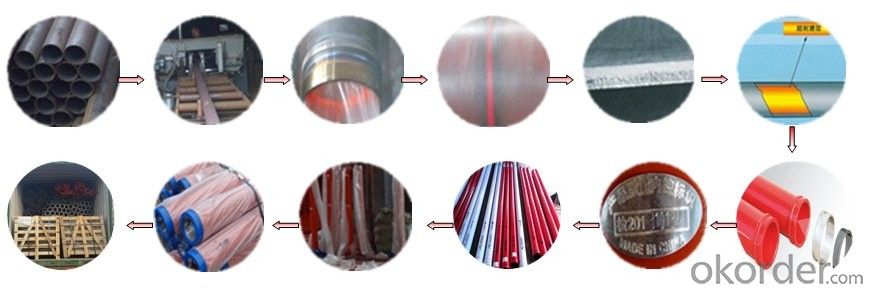

3. Concrete Pump Spare Parts 45Mn2 Boom Pipe Images:

4. Concrete Pump Spare Parts 45Mn2 Boom Pipe Specification:

Name | Data |

Material | 45MN2/20#/16MN/Q345 |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

Process | High temperature quenching |

HRC | 65 |

Production Process

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

- Q: What is the role of a concrete pump hopper agitator blade?

- The role of a concrete pump hopper agitator blade is to mix and agitate the concrete mixture in the hopper, ensuring a consistent and homogeneous mixture. This helps to prevent the concrete from settling or becoming too thick, allowing for a smoother and more efficient pumping process.

- Q: What are the different types of concrete pump hopper agitator blades?

- In the construction industry, there exists a variety of concrete pump hopper agitator blades. These blades have different designs and functions, all aimed at efficiently mixing and agitating the concrete mixture in the hopper. By achieving a consistent and homogeneous mixture, the concrete can be pumped onto the project site effectively. 1. Paddle Blades: The most commonly used agitator blades in concrete pump hoppers are paddle blades. These blades have a flat, paddle-like design that effectively mixes the concrete ingredients. They are typically made of high-quality steel or hardened rubber to ensure durability and optimal performance. 2. Helical Blades: Another type of agitator blade is the helical blade, which has a spiral shape. This design creates a gentle, swirling motion within the hopper, preventing the formation of lumps and ensuring a smooth and well-mixed concrete mixture. 3. Ribbon Blades: Thin and flat, ribbon blades resemble ribbons and are placed vertically in the hopper. They rotate along their axis to thoroughly mix the concrete ingredients. Ribbon blades are known for their ability to prevent clogging and improve the efficiency of concrete pumping. 4. Fan Blades: With a unique fan-shaped design, fan blades create a powerful airflow within the hopper to agitate the concrete mixture. This type of blade is particularly effective in preventing the segregation of concrete ingredients and maintaining a consistent mixture. 5. Tine Blades: Tine blades feature multiple prongs or tines extending from a central hub. They provide a more aggressive agitation action, making them suitable for mixing heavier concrete mixes or those containing large aggregates. The selection of agitator blades depends on various factors, such as the type of concrete, desired consistency, and specific project requirements. It is crucial to choose the appropriate blade type and perform regular maintenance to optimize the performance and lifespan of the concrete pump hopper agitator.

- Q: Are there any specific maintenance practices for concrete pump spare parts?

- Concrete pump spare parts should be regularly inspected for signs of wear or damage. This involves checking for visible defects like cracks, leaks, or any other issues. If any problems are found, the spare parts should be immediately replaced or repaired to prevent further damage. Regular cleaning is also essential for concrete pump spare parts. These parts often come into contact with cement, water, and other substances that can cause build-up and affect their performance. Cleaning them regularly will remove debris and residue, ensuring optimal functionality. Lubrication is another important maintenance practice for concrete pump spare parts. Properly lubricating moving components like bearings, seals, and pistons reduces friction and wear, extending the lifespan of the parts. It's crucial to use the correct lubricants recommended by the manufacturer and follow their application guidelines. Proper storage is also vital for maintaining spare parts. They should be stored in a clean, dry environment, away from chemicals or substances that could damage them. Additionally, spare parts should be protected from physical damage, such as being dropped or bumped. Lastly, it's recommended to adhere to the manufacturer's maintenance and replacement guidelines. Regular servicing and inspections by qualified technicians can help identify potential issues early on and prevent major breakdowns or failures. In summary, following specific maintenance practices like regular inspection, cleaning, lubrication, proper storage, and adherence to manufacturer's guidelines are crucial for ensuring optimal performance and longevity of concrete pump spare parts.

- Q: How can one determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts?

- To determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts, one can refer to the manufacturer's recommendations and specifications. These guidelines will outline the appropriate viscosity grade and temperature range for optimal performance and longevity of the spare parts. It is important to follow these recommendations to ensure efficient lubrication and protection of the concrete pump components. Additionally, consulting with industry experts or conducting research on lubrication requirements specific to concrete pump spare parts can also provide valuable insights for determining the correct viscosity and temperature range.

- Q: How to deal with the blockage in the outlet of the distributing valve of the concrete pump?

- If this method does not dare, it can only be manually removed, remove the connecting pipe, remove the debris in the valve.

- Q: How often should hopper agitator shafts be inspected or replaced in a concrete pump?

- Hopper agitator shafts in a concrete pump should be regularly inspected and maintained to ensure optimal performance and prevent potential breakdowns. The frequency of inspection or replacement depends on several factors such as the usage and operating conditions of the pump. As a general guideline, it is recommended to inspect the hopper agitator shafts at least once every three to six months. During the inspection, the shafts should be checked for any signs of wear, damage, or misalignment. If any issues are detected, appropriate measures should be taken, such as lubrication, realignment, or replacement of damaged parts. However, it is important to note that the frequency of inspection may vary depending on the intensity of use, the type of materials being pumped, and the overall condition of the pump. For instance, if the pump is subjected to heavy-duty or continuous operation, it may be necessary to inspect the agitator shafts more frequently, such as on a monthly basis. Regular maintenance and inspection of hopper agitator shafts not only ensure the smooth operation of the concrete pump but also extend the lifespan of the equipment. Timely detection and resolution of any issues can prevent costly repairs or downtime in the future. Additionally, following the manufacturer's recommendations and guidelines for maintenance can help optimize the performance and reliability of the concrete pump.

- Q: What are the different types of concrete pump rubber hoses?

- In the market, you can find a variety of concrete pump rubber hoses. These hoses come in different types to cater to specific needs. The first type is the Steel Wire Reinforced Hose, which is the most commonly used. It is built with multiple layers of steel wire to provide maximum strength and durability. This type of hose is suitable for high-pressure applications and can handle the heavy pumping of concrete effortlessly. Another type is the Textile Reinforced Hose, which is reinforced with multiple layers of textile fabric like nylon or polyester. These hoses are lighter in weight compared to the steel wire reinforced ones, making them easier to handle and maneuver. They are suitable for medium-pressure applications and are commonly used in smaller concrete pumps. Then there is the Fabric Hose, which is made from a single layer of fabric like nylon or polyester. These hoses are lightweight and flexible, making them easy to handle and transport. Fabric hoses are suitable for low-pressure applications and are commonly used in small-scale construction projects. Composite Hoses are made from a combination of different materials such as rubber and plastic. These hoses are lightweight and highly flexible, which makes them ideal for applications where maneuverability is crucial. They are commonly used in smaller concrete pumps and can handle both low and medium pressure. Lastly, there are Flanged Hoses, which have flanges attached at both ends. These flanges are used to connect the hose to the pump and the nozzle, providing a secure connection and preventing any leaks or disconnections during the pumping process. Flanged hoses are commonly used in high-pressure applications and are suitable for large-scale construction projects. In conclusion, the choice of concrete pump rubber hose depends on specific project requirements. Factors such as pressure, size, and type of concrete being pumped should be considered to ensure efficient and safe concrete pumping operations.

- Q: What are the signs of a damaged concrete pump agitator motor?

- There are several signs that can indicate a damaged concrete pump agitator motor. 1. Unusual noises: If you hear excessive grinding, rattling, or squeaking noises coming from the agitator motor, it could be a sign of damage. These noises may indicate worn-out bearings or other internal components that need attention. 2. Inconsistent operation: A damaged agitator motor may result in irregular or inconsistent mixing of the concrete. If you notice that the concrete is not being mixed properly or if the agitation speed is inconsistent, it could be a sign that the motor is damaged. 3. Overheating: If the agitator motor becomes excessively hot during operation, it may indicate a problem. Overheating can be caused by various issues, such as a faulty motor or insufficient lubrication. In such cases, it is important to address the issue promptly to prevent further damage and potential breakdown. 4. Vibrations: Excessive vibrations during operation can be a sign of a damaged motor. Vibrations may occur due to imbalanced or misaligned components within the motor, which can result in reduced efficiency and increased wear and tear. 5. Electrical issues: If the motor is experiencing electrical problems, such as tripping circuit breakers or blowing fuses, it could indicate a damaged motor. Faulty wiring, short circuits, or damaged electrical components can lead to these issues and should be addressed by a professional. 6. Reduced performance: A damaged agitator motor may result in reduced performance or decreased efficiency. If you notice that the agitator is not working as effectively as it used to or if the concrete is not being mixed thoroughly, it could be a sign of motor damage. In any case, if you suspect that the concrete pump agitator motor is damaged, it is recommended to consult a professional technician or service provider familiar with concrete pump machinery. They can diagnose the issue accurately and provide appropriate solutions to repair or replace the damaged motor.

- Q: What is the function of a concrete pump hopper grate handle?

- The function of a concrete pump hopper grate handle is to provide a means of manually controlling the opening and closing of the hopper grate on a concrete pump. The hopper grate is a crucial component of the pump that allows for the introduction of concrete into the pumping system. By operating the handle, the operator can adjust the position of the grate to regulate the flow of concrete and prevent any large debris or foreign objects from entering the pumping system. This helps to ensure the smooth operation of the pump and maintain the quality of the concrete being pumped. Additionally, the handle allows for easy and convenient access to the hopper grate for maintenance and cleaning purposes. Overall, the concrete pump hopper grate handle plays a vital role in controlling the flow of concrete and maintaining the efficiency and reliability of the pumping process.

- Q: Can I get spare parts for both piston and rotary concrete pumps?

- Yes, you can get spare parts for both piston and rotary concrete pumps. Many manufacturers and suppliers offer a wide range of spare parts for these types of pumps. These parts include but are not limited to pistons, seals, valves, wear plates, hydraulic components, and bearings. It is important to ensure that you purchase genuine spare parts from reputable suppliers to ensure the quality and compatibility with your specific pump model. Additionally, it is recommended to have a regular maintenance and inspection schedule for your concrete pump to identify any worn-out parts and replace them promptly to avoid any potential breakdowns or disruptions in your construction projects.

Send your message to us

Concrete Pump Spare Parts 45Mn2 Boom Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords