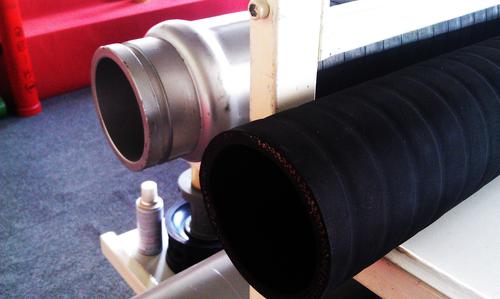

Concrete Pump Rubber End Hose

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Size: 2"-6" (DN50-DN150)

Maximum length: 20 metres

Flange: Schwing, Putzmeister, Sany

Plies of wire or fabric: 2/4

Working pressure: 1200psi

Burst pressure: 3000psi

Other products:

1) Putzmeister/ Schwing/ Zoomlion/ Sermac RamPistons

2) Putzmeister/ IHI/ Kyokuto/ Zoomlion/Sany Seperated Piston

3) Wear-resisting board and Cuts ink

4) Coupling and seal ring for Putzmeister,Schwing, Sany

5) ST52 steel pipe, elbow, reducer

6) Cleaning seriesand other- Q: What is the purpose of a concrete pump electric motor?

- The purpose of a concrete pump electric motor is to provide the necessary power and torque to pump concrete from one location to another, eliminating the need for manual labor and increasing efficiency in construction projects.

- Q: How long do concrete pump pipes typically last?

- Concrete pump pipes typically last between 25,000 to 40,000 cubic meters of concrete pumped. However, the lifespan of these pipes can vary based on several factors such as the quality of the pipes, the type of concrete being pumped, the pumping pressure, and the maintenance practices followed. Regular inspections, cleaning, and proper storage can help extend the lifespan of concrete pump pipes. Ultimately, it is essential to monitor the wear and tear of the pipes and replace them when necessary to ensure efficient and safe concrete pumping operations.

- Q: How do I properly maintain and replace hydraulic motors in concrete pump spare parts?

- To ensure smooth operation and long-lasting performance of concrete pump spare parts, it is crucial to properly maintain and replace hydraulic motors. Here are some effective steps to guide you: 1. Regularly inspect the hydraulic motors to detect any signs of wear, damage, or leaks. Ensure the fluid levels are at the recommended levels. 2. Keep the hydraulic motors clean by removing dirt, debris, and contaminants. This prevents overheating and minimizes the risk of internal component damage. 3. Follow the manufacturer's recommendations and regularly check and change the hydraulic fluid. Clean and replace filters to prevent damage-causing particles. 4. Lubricate the hydraulic motors according to the manufacturer's instructions. This reduces friction and wear on moving parts, improving overall performance and lifespan. 5. Operate the concrete pump within the recommended load and pressure limits specified by the manufacturer. Excessive pressure or overloading can stress the hydraulic motors, leading to premature failure. 6. Keep track of the service life and usage of hydraulic motors. Over time, they may become less efficient. Promptly replace them to avoid disruptions to concrete pumping operations. 7. If unsure about maintenance or replacement, seek professional assistance. Professionals have the expertise to carry out tasks correctly, ensuring safety and optimal performance of concrete pump spare parts. By following these steps, you can effectively maintain and replace hydraulic motors in concrete pump spare parts, ensuring equipment longevity and efficiency.

- Q: How can I determine if the concrete pump cylinder needs replacement?

- To determine if the concrete pump cylinder needs replacement, you should inspect it for any visible signs of wear or damage. Look for cracks, leaks, or excessive corrosion on the cylinder. Additionally, monitor the pump's performance and check if there are any irregularities or issues during operation, such as decreased pumping efficiency or increased noise. It is also recommended to consult with a professional concrete pump technician or manufacturer for a thorough inspection and assessment of the cylinder's condition.

- Q: What are the potential risks associated with the installation and replacement of concrete pump spare parts?

- The installation and replacement of concrete pump spare parts come with various potential risks. Improper installation is a key risk, as it can cause leaks, reduced performance, and even equipment failure. This not only leads to expensive repairs but also poses a safety threat to workers and those nearby. Another risk is the use of counterfeit or low-quality spare parts. These parts may not meet the necessary standards, compromising the integrity and functionality of the concrete pump. This increases the likelihood of equipment failure and accidents. Moreover, the installation and replacement process may involve operating heavy machinery like cranes or forklifts, which can be dangerous if not done correctly. Inadequate precautions can result in accidents, injuries, or damage to the equipment or surrounding structures. Additionally, concrete pump spare parts may contain hazardous materials or substances. Workers must be aware of the risks associated with handling and disposing of these materials, such as exposure to harmful chemicals or environmental contamination. Lastly, there is a risk of delays and downtime during the installation and replacement process. If spare parts are not readily available or compatibility issues arise, equipment may be inoperable for extended periods. This can cause project delays, increased costs, and potential financial losses. To mitigate these risks, it is crucial to provide proper training and supervision to workers involved in the installation and replacement of concrete pump spare parts. Using genuine and high-quality spare parts from reputable suppliers can also reduce the risk of equipment failure. Regular inspections, maintenance, and adherence to safety protocols are essential to minimize potential risks associated with this process.

- Q: How often should hydraulic cylinders be inspected or replaced in a concrete pump?

- Hydraulic cylinders in a concrete pump should be inspected regularly, ideally every 500 hours of operation or at least once a year, whichever comes first. However, it is important to note that the frequency of inspections may vary depending on the specific conditions and usage of the concrete pump. During inspections, qualified technicians should thoroughly examine the hydraulic cylinders for any signs of wear, damage, or leaks. They should also check the alignment, piston rods, seals, and other components to ensure proper functioning. If any issues are found, such as excessive wear or leaks, it is recommended to replace the hydraulic cylinders promptly to prevent further damage and maintain optimal performance. Regular inspections and timely replacements of hydraulic cylinders are crucial for ensuring the safety, efficiency, and longevity of a concrete pump. Neglecting proper maintenance can lead to costly repairs, decreased productivity, and even accidents. Therefore, it is essential to follow manufacturer's guidelines and consult with professionals to determine the appropriate inspection and replacement intervals for hydraulic cylinders in a concrete pump.

- Q: What is the purpose of a concrete pump hydraulic oil cooler?

- The purpose of a concrete pump hydraulic oil cooler is to maintain the optimal temperature of the hydraulic oil in the system. Hydraulic oil is used to power the pump's hydraulic system, which is responsible for operating various components such as the pistons, cylinders, and valves. During the pumping process, the hydraulic oil can become heated due to the constant movement and pressure exerted on the system. If the oil temperature rises too high, it can lead to a decrease in viscosity, which affects the overall performance and efficiency of the pump. Additionally, excessive heat can cause the hydraulic oil to break down and degrade, resulting in increased wear and tear on the pump's components. To prevent these issues, a concrete pump hydraulic oil cooler is used. It is typically a heat exchanger that transfers heat from the hydraulic oil to a cooling medium, such as air or water. This helps to regulate the temperature of the hydraulic oil and keep it within a safe operating range. By maintaining the optimal temperature, the hydraulic oil cooler ensures that the hydraulic system operates efficiently and effectively. It helps to prolong the lifespan of the pump by reducing the risk of overheating and excessive wear on the components. Additionally, it helps to maintain the quality of the hydraulic oil, allowing it to retain its lubricating properties and prevent any potential damage to the system. In summary, the purpose of a concrete pump hydraulic oil cooler is to regulate the temperature of the hydraulic oil in order to optimize the performance, efficiency, and longevity of the pump's hydraulic system.

- Q: How long do concrete pump hoses typically last?

- The lifespan of concrete pump hoses usually ranges from 5 to 10 years, contingent upon factors like usage, maintenance, and the hose's quality. Over time, the hose can deteriorate due to typical wear and tear, exposure to harsh chemicals, and extreme weather conditions. To prolong the hose's life, it is crucial to perform proper upkeep such as regular cleaning, inspection, and replacement of worn-out components. Nonetheless, it is essential to emphasize the significance of regularly monitoring and replacing hoses to guarantee the safety and effectiveness of the concrete pumping process.

- Q: Can concrete pump valves be repaired or should they be replaced?

- Concrete pump valves can often be repaired instead of being replaced. The decision to repair or replace a concrete pump valve depends on the extent of the damage and the cost-effectiveness of each option. In some cases, minor issues such as clogs or leaks can be easily fixed by cleaning or replacing smaller components. However, if the valve is severely damaged or worn out, replacement may be the more practical solution. It is recommended to consult with a professional concrete pump technician to assess the condition of the valve and determine the best course of action.

- Q: How do I properly maintain and replace wear plates in concrete pump spare parts?

- Properly maintaining and replacing wear plates in concrete pump spare parts is crucial for the optimal performance and longevity of your equipment. Here are the steps you can follow to ensure that the wear plates are properly maintained and replaced: 1. Regular inspection: It is important to regularly inspect the wear plates in your concrete pump spare parts to identify any signs of wear or damage. Look for cracks, excessive wear, or any other visible signs of deterioration. 2. Cleaning: Before replacing the wear plates, make sure to clean the area around them thoroughly. Remove any debris, dirt, or hardened concrete that might be present. Use a pressure washer or a wire brush to clean the surface properly. 3. Measure wear plate thickness: Measure the thickness of the wear plates using a precision measuring tool. Compare the current thickness with the manufacturer's recommended specifications to determine if replacement is necessary. If the wear plates are below the recommended thickness, it is time to replace them. 4. Remove old wear plates: Carefully remove the old wear plates using appropriate tools. Take note of their positions and any alignment marks to ensure correct installation of the new plates. 5. Prepare new wear plates: Before installing the new wear plates, ensure that they are of the correct size and specifications for your concrete pump. Check for any defects or damage in the new plates before proceeding. 6. Apply lubrication: Apply a thin layer of lubricant or anti-seize compound on the mating surface of the new wear plates. This will help prevent corrosion and ease future replacement. 7. Install the new wear plates: Position the new wear plates in the correct location, aligning them with any reference marks or indicators. Secure them tightly using the appropriate bolts or fasteners, making sure not to overtighten. 8. Test and check alignment: Once the new wear plates are installed, perform a test run of the concrete pump to ensure that everything is functioning properly. Check for any leaks, unusual vibrations, or misalignments. If any issues are detected, address them promptly. 9. Maintain regular maintenance schedule: To prevent premature wear and damage to the wear plates, establish a regular maintenance schedule. This may include cleaning, lubricating, and inspecting the wear plates at specified intervals or after a certain number of hours of operation. By following these steps and maintaining a proactive approach to wear plate maintenance and replacement, you can ensure the smooth operation and prolonged lifespan of your concrete pump spare parts.

Send your message to us

Concrete Pump Rubber End Hose

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords