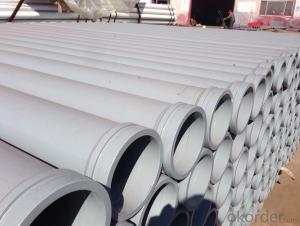

Concrete Pump Deliver Pipe DN125-3 MTR with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name: Concrete Pump Pipe

1. Specification

Delivery Pipe DN125-3 MTR

Thickness 3.2mm

Material:Q235

2. Application

Concrete mixing and delivery.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Concrete Pump Delivery Pipe according to customers request?

A4: Yes, we can produce Concrete Pump Delivery Pipe according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: How often should hopper grate clamps be inspected or replaced in a concrete pump?

- Hopper grate clamps in a concrete pump should be inspected regularly, ideally every 500 hours of operation, or at least once every six months. However, the frequency of inspection and replacement may vary depending on the specific conditions and usage of the concrete pump. It is important to closely monitor the condition of the clamps and replace them promptly if any signs of wear, damage, or loosening are observed to ensure optimal performance and safety.

- Q: What are the signs of a clogged or damaged hydraulic filter?

- A clogged or damaged hydraulic filter may be indicated by several signs. One of the most common signs is a decrease in hydraulic system performance. If you observe a decrease in the speed or power of your hydraulic equipment, it may be due to a clogged filter that restricts the flow of hydraulic fluid. Another sign is an increase in heat within the hydraulic system. As the system struggles to maintain proper fluid flow and pressure, a clogged or damaged filter can cause it to overheat. Furthermore, unusual noises may be noticed coming from the hydraulic system. A clogged filter can result in air becoming trapped in the system, leading to strange noises like whining or grinding. Moreover, the presence of dirty or discolored hydraulic fluid could suggest a clogged or damaged filter. The filter's purpose is to remove dirt and contaminants from the fluid, so if it fails to do so effectively, the fluid will become dirty and discolored. Finally, frequent or recurring issues with the hydraulic system could be an indication of a clogged or damaged filter. The filter plays a critical role in maintaining the overall health of the hydraulic system, so if it is not functioning properly, it can lead to other problems such as pump failure or valve blockages. Regular inspection and replacement of hydraulic filters are crucial to ensure the proper functioning and longevity of your hydraulic system.

- Q: Can concrete pump spare parts be used interchangeably between different pump brands or models?

- No, concrete pump spare parts cannot be used interchangeably between different pump brands or models. Each pump brand and model is designed with specific specifications and dimensions, so the spare parts need to be specifically manufactured to fit those requirements. Attempting to use spare parts from a different brand or model may result in compatibility issues or even damage to the pump. It is always recommended to use genuine spare parts from the same brand or model to ensure proper functioning and longevity of the pump.

- Q: How can a faulty concrete pump S valve affect the concrete flow?

- A faulty concrete pump S valve can affect the concrete flow by causing disruptions, blockages, or uneven distribution of the concrete. The S valve is responsible for controlling the direction of the concrete flow, and when it malfunctions, it can lead to decreased or inconsistent flow rates. This can result in delays in the construction process, poor concrete quality, or even damage to the pump system.

- Q: Are there any specific guidelines for the storage and handling of concrete pump spare parts during transportation?

- Yes, there are specific guidelines for the storage and handling of concrete pump spare parts during transportation. These guidelines include ensuring proper packaging and labeling of the spare parts, using appropriate containers or packaging materials to protect them from damage, securely fastening and securing the spare parts to prevent movement during transit, and following any specific instructions provided by the manufacturer for handling and storing the spare parts. It is also important to consider factors such as temperature, humidity, and potential hazards during transportation to ensure the integrity and quality of the spare parts.

- Q: Can I get spare parts for both single-cylinder and multi-cylinder concrete pumps?

- Yes, you can get spare parts for both single-cylinder and multi-cylinder concrete pumps. Many manufacturers and suppliers offer spare parts for different types of concrete pumps, including both single-cylinder and multi-cylinder models. These spare parts can include components such as hydraulic cylinders, pistons, seals, valves, hoses, and other essential parts that may need replacement due to wear and tear or damage. It is essential to reach out to the specific manufacturer or supplier of your concrete pump to inquire about the availability and compatibility of spare parts for your particular model.

- Q: Can I get spare parts for both piston and rotary concrete pumps?

- Yes, you can get spare parts for both piston and rotary concrete pumps. Many manufacturers and suppliers offer a wide range of spare parts for these types of pumps. These parts include but are not limited to pistons, seals, valves, wear plates, hydraulic components, and bearings. It is important to ensure that you purchase genuine spare parts from reputable suppliers to ensure the quality and compatibility with your specific pump model. Additionally, it is recommended to have a regular maintenance and inspection schedule for your concrete pump to identify any worn-out parts and replace them promptly to avoid any potential breakdowns or disruptions in your construction projects.

- Q: What is the role of a concrete pump hopper vibrator?

- The role of a concrete pump hopper vibrator is to ensure the smooth and efficient flow of concrete from the hopper into the pump. It helps to prevent clogging and blockages by vibrating the hopper, which loosens the concrete and allows it to flow freely into the pump.

- Q: What are the key considerations when purchasing spare parts for a concrete pump?

- When purchasing spare parts for a concrete pump, there are several key considerations that need to be taken into account. These considerations include the compatibility of the spare parts with the specific make and model of the concrete pump, the quality and reliability of the spare parts, the availability of the spare parts, and the cost-effectiveness of the purchase. First and foremost, it is crucial to ensure that the spare parts being purchased are compatible with the concrete pump in question. Concrete pumps come in various makes and models, and each may have specific requirements in terms of spare parts. Therefore, it is essential to carefully match the specifications and requirements of the concrete pump with the spare parts being purchased to ensure proper functionality and performance. The quality and reliability of the spare parts are also vital considerations. Investing in high-quality spare parts can significantly impact the efficiency and longevity of the concrete pump. It is advisable to choose spare parts from reputable manufacturers or suppliers who have a proven track record of producing reliable products. Conducting thorough research and reading customer reviews can help in assessing the quality and reliability of the spare parts. Availability is another important factor to consider when purchasing spare parts for a concrete pump. It is essential to ensure that the spare parts needed are readily available, either from local suppliers or through efficient delivery channels. A delay in obtaining the necessary spare parts can lead to extended downtime and increased costs. Therefore, it is recommended to choose suppliers who have a reliable and efficient distribution network. Cost-effectiveness is also a key consideration when purchasing spare parts. While it is important to prioritize quality and reliability, it is equally important to find spare parts that offer good value for money. Comparing prices from different suppliers and considering the lifespan and potential maintenance costs of the spare parts can help in making a cost-effective decision. It is crucial to strike a balance between cost and quality to ensure the best return on investment. In conclusion, when purchasing spare parts for a concrete pump, it is important to consider compatibility, quality, availability, and cost-effectiveness. By carefully evaluating these key considerations, one can ensure that the spare parts chosen will meet the specific needs of the concrete pump, maintain its performance and reliability, and provide value for money.

- Q: What are the different types of concrete pump hopper screens?

- The different types of concrete pump hopper screens include wire mesh screens, perforated plate screens, and synthetic fiber screens.

Send your message to us

Concrete Pump Deliver Pipe DN125-3 MTR with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords