Competitive Price Aluminum Honeycomb Sheets of Aluminum Siding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Honeycomb Sheet Description:

Aluminum honeycomb panels are made of aluminum alloy plates roller coated with PVDF while in the milddle are the aluminum honeycombs which meets the international earonautical standards. This product is specially make with the cold-glue and hot-press technology.

The structural honeycomb core provides strength and consistent rigidity at a very low desity; When bonded to similarly lightweight facings. Every honeycomb cell wall acts like the web of an I-Beam, forming an extremely strong and rigid lightweight composite panel.

2.Main Features of Aluminum Honeycomb Sheet:

Reasonable and stable chemical composition

Accurate tolerance

Nice mechanical property

Standards: EN, ASTM and JIS

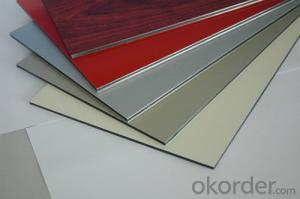

3. Aluminum Honeycomb Sheet Images:

4. Aluminum Honeycomb Sheet Specification:

| Thickness | Unit | 6 mm | 10 mm | 15 mm | 20 mm | 25 mm | ||

| Cover sheet thickness, front | [mm] | 1.0 | ||||||

| Cover sheet thickness, rear | [mm] | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| Weight | [kg/m²] | 4.7 | 5.0 | 6.7 | 7.0 | 7.3 | ||

| Technical properties | ||||||||

| Section modulus | W | [cm³/m] | 2.6 | 4.6 | 14 | 19 | 24 | |

| Rigidity | E@J | [kNcm²/m] | 7.100 | 21.900 | 75.500 | 138.900 | 221.600 | |

| Alloy / Temper of Aluminium Layers | Peraluman alloy (AIMg), H42 acc. EN 573-3 | |||||||

| Modulus of Elasticity | E | [N/mm²] | 70.000 | |||||

| Tensile Strength of Aluminium | R m | [N/mm²] | ≥ 125 | |||||

| 0.2 % Proof Stress | R p0,2 | [N/mm²] | ≥ 80 | |||||

| Elongation | A 50 | [%] | ≥ 5 | |||||

| Linear Thermal Expansion | α | 2.4 mm/m at 100ºC temperature difference | ||||||

| Core | ||||||||

| Aluminium foils from AIMn alloys (EN AW-3003) Bare comprehensive strength | [N/mm²] | > 2.5 | ||||||

| Weight | [kg/m³] | > 50 | ||||||

| Surface | ||||||||

| Lacquering | Coil Coating Fluorocarbon based (e.g. PVDF) | |||||||

| Gloss (initial value) | [%] | 25-40 | ||||||

| Pencil Hardness | HB-F | |||||||

| Acoustical Properties | ||||||||

| Sound Absorption Factor | α s | 0.05 | ||||||

| Airborne sound insulation index (acc. to ISO 717-1, ISO 140-3) | R w | [dB] | 21 | 21 | 22 | 23 | 25 | |

| Thermal Properties | ||||||||

| Termal conductivity (regarding total thickness, incl. cover sheets) | λ | [W/mK] | 0.95 | 1.35 | 1.78 | 2.25 | 2.70 | |

| Thermal resistance | R | [m²K/W] | 0.0063 | 0.0074 | 0.0084 | 0.0089 | 0.0093 | |

| Temperature Resistance | [ºC] | -40 to +80 | ||||||

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process..

- Q: What are the safety precautions when working with aluminum sheets?

- To ensure your well-being while working with aluminum sheets, it is crucial to adhere to certain safety measures. Here are some important guidelines to consider: 1. Personal Protective Equipment (PPE): Safeguard yourself from potential hazards by consistently wearing appropriate PPE, such as safety goggles, gloves, and a face mask. Aluminum sheets can cause injury if they come into contact with your eyes, skin, or respiratory system due to sharp edges, metal filings, or dust particles. 2. Ventilation: Minimize the accumulation of aluminum dust or fumes by ensuring proper ventilation in your work area. This is particularly important when cutting or shaping aluminum sheets to prevent inhaling harmful airborne particles. 3. Handling and storage: Handle aluminum sheets with care to prevent injuries, as they may have sharp edges. It is essential to wear gloves while handling them. Additionally, store the sheets securely and in an organized manner to avoid accidents like tripping or falling. 4. Cutting and shaping: Utilize appropriate tools specifically designed for cutting or shaping aluminum sheets. Refrain from using tools unsuitable for aluminum, as they can cause damage or create unsafe conditions. Make sure the cutting area is free of clutter and maintain awareness of your body position to prevent accidents. 5. Fire safety: Exercise caution regarding fire hazards since aluminum is highly flammable. Keep flammable materials away from your work area and avoid using open flames or sparks nearby. Be prepared for a fire by having a readily accessible fire extinguisher and knowing how to use it effectively. 6. Training and knowledge: Acquire proper training and knowledge concerning working with aluminum sheets. Understanding the properties of aluminum, appropriate techniques, and safety precautions can effectively prevent accidents and injuries. 7. Regular maintenance: Maintain your tools and equipment in good working condition. Regularly inspect them for any damage or signs of wear and tear, and promptly replace or repair as necessary. Faulty or poorly maintained tools can increase the risk of accidents when working with aluminum sheets. By adhering to these safety precautions, you can minimize potential risks and ensure a safe working environment when handling aluminum sheets.

- Q: Can aluminum sheet be painted?

- Certainly, painting aluminum sheet is possible. However, it is crucial to adequately prepare the surface beforehand to guarantee strong paint adhesion and long-lasting results. Typically, this involves thoroughly cleaning the aluminum sheet to eliminate any dirt, grease, or oxidation. Subsequently, a primer is applied to enhance adhesion. Once the primer has dried, you can proceed with applying your desired paint. For optimal outcomes, it is recommended to select a high-quality paint suitable for metal surfaces. Moreover, if the aluminum sheet will be exposed to outdoor conditions, it is advisable to utilize a paint specifically designed for exterior use. This will ensure protection against weathering and corrosion.

- Q: Are aluminum sheets suitable for HVAC ductwork?

- Indeed, HVAC ductwork can be made using aluminum sheets. The lightweight and durable characteristics of aluminum make it a favored option for ductwork. Its resistance to corrosion is crucial in HVAC systems where moisture and condensation are prevalent. Moreover, aluminum ductwork exhibits excellent thermal conductivity, enabling efficient heat transfer. Furthermore, the simplicity of working with aluminum sheets renders installation and maintenance relatively easy. Ultimately, aluminum sheets guarantee dependable performance and energy efficiency, making them a trustworthy selection for HVAC ductwork.

- Q: Can 101 aluminum sheets be used in HVAC systems?

- Yes, 101 aluminum sheets can be used in HVAC systems.

- Q: What is the most effective technique for applying a coating to aluminum sheets?

- <p>The best method for coating aluminum sheets depends on the desired application and properties of the coating. Common methods include anodizing, which provides a protective oxide layer, powder coating for a durable finish, and electroplating for enhanced corrosion resistance. For decorative purposes, methods like painting or vacuum deposition can be used. Each method has its advantages and is chosen based on factors such as cost, durability, and aesthetic requirements.</p>

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- Aluminum foil can’t be used for heat retaining, it’s unsafe and hasn’t good efficiency. In this case, advice you use refractory cement to knot the coil and connect porcelain tube in the middle. It will Largely reduce the energy consumption produced by heat radiation.

- Q: Are aluminum sheets suitable for decorative purposes?

- Yes, aluminum sheets are suitable for decorative purposes. They are lightweight, durable, and versatile, making them ideal for various decorative applications such as wall panels, signage, furniture accents, and more. Additionally, aluminum sheets can be easily cut, shaped, and finished to achieve the desired decorative effect, making them a popular choice among designers and architects.

- Q: Hey I just noticed that my deodorant/antiperspirant has aluminum in it. I remember reading that this is bad for you. My question is, will this be dangerous for my health in the long run?

- Yes. Use natural.

- Q: Curtain wall aluminum plate reinforcement spacing between the number of appropriate, the country has no standard?

- As to the stiffener of the aluminum veneer, what are the following points?:1, aluminum reinforcement spacing is generally around 600mm, in order to ensure the aluminum plate in the positive and negative pressure conditions within the scope of deformation. When aluminum plate is welded, there is internal stress due to welding deformation (this internal stress can not be completely eliminated for a long time), and the rigidity of reinforcing bar should also be increased.2. The sectional dimension and spacing of stiffeners shall be determined according to the calculated wind pressure of the aluminum plate. But it is worth noting that the reinforcement calculation of single aluminum plate strengthening is different from the glass curtain wall, first, its strength is certainly no problem (still not seen the wind blowing broken plate, there is no joke) deflection possibility, bend off and windy weather also very few people to pay attention to the single aluminum plate plate surface after deformation the scenery. Therefore, the calculation of deflection of stiffeners are considered under the condition of wind strength and deflection when the winds of aluminum can cause permanent plastic deformation.In fact, aluminum veneer manufacturers generally use the single aluminum plate edge folding groove made of aluminum and 20*40*20, installed in the distance about 600mm. Also useful for profile (grooved aluminum) stiffenersThe spacing between stiffeners is very important to the cost of production. Generally speaking, the spacing of stiffeners will be changed from 600 to 350, and the cost will be increased by 8~15 yuan / square meter

- Q: How to press multilayer aluminum sheets (aluminum sheet's thickness: 0.2mm) together and keep them inseperate after pressing?

- resistance welding usually overlays two pieces together and presses them, heating them to melting state through current, you can try multiple sheets.

Send your message to us

Competitive Price Aluminum Honeycomb Sheets of Aluminum Siding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords