Decorative and Constructive Aluminum Honeycomb Sheets with Coated Embossed Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

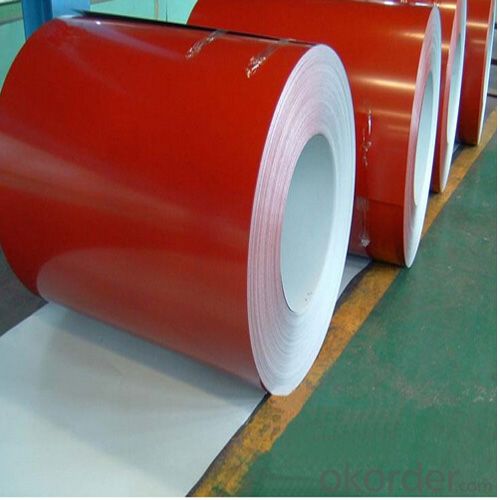

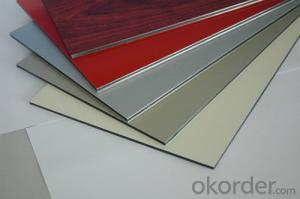

1.Structure of Coated Aluminium Embossed Coils for Decoration and Construction Description:

The main products of our company are aluminium sheet, coil, aluminium stucco embossed sheet, five-bars embossed sheet, diamond embossed sheet, color coated aluminium sheet, aluminium foil and aluminium circle. They are widely used in daily life. The aluminum sheets are used in many places, transportation, decoration, construction and so on.

The function is Fire-proofing, Water-proofing, Heat-resistance, Anti-static, Voice-resistance, Mositure-proofing, Corrosion Resistance. The Application is Decoration and Transporation, Wall, Window and Door, Antiskid Board.

2.Main Features of Coated Aluminium Embossed Coils for Decoration and Construction:

Coating Thickness: 0.01mm-0.15mm, 0.02mm0.025mm

Surface Treatment: Color Coated, Embossed

Coating Color: Red, Green, Blue, etc

Coating: PE/PVDF

Surface: One Side Bright, Two Sides Brigh

3. Coated Aluminium Embossed Coils for Decoration and Construction Images:

4. Coated Aluminium Embossed Coils for Decoration and Construction Specification:

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

| 1060 | 0.2 | 0.25 | 0.05 | 0.03 | 0.03 | 0.05 | 0.015-0.02 | 99.6 |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.015-0.02 | 99.5 |

| 1100 | 0.2 | 0.5-0.6 | 0.05 | 0.05 | - | 0.05 | 0.015-0.02 | 99.0 |

| 1235 | 0.65 | 0.05 | 0.05 | 0.05 | 0.1 | 0.06 | 99.35 | |

| 3003 | 0.2 | 0.3-0.45 | 0.05-0.15 | 1.05-1.35 | - | 0.10 | - | - |

| 3102 | 0.2 | 0.1-0.4 | <0.1< span=""> | 0.1-0.4 | - | <0.05< span=""> | <0.05< span=""> | - |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.4 | 0.1 | - |

| 5052 | 0.088 | 0.296 | 0.007 | 0.038 | 2.253 | 0.009 | 0.012 | - |

| 8011 | 0.55-0.59 | 0.69-0.75 | 0.02 | 0.025 | 0.01 | 0.01 | 0.015-0.02 | - |

| 5083 | 0.4 | 0.4-1.0 | 4.0-4.9 | 0.25 | R | |||

| 5754 | 0.07 | 0.3 | 0.006 | 0.18 | - | - | 0.016 | R |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.25 | 0.15 | R |

| 6082 | 0.8-1.5 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.2 | 0.1 | R |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum sheets be textured or patterned?

- Yes, aluminum sheets can be textured or patterned. There are various techniques that can be used to create textures or patterns on aluminum sheets, such as embossing, engraving, or etching. These methods involve altering the surface of the aluminum sheet to create a desired texture or pattern. Additionally, aluminum sheets can also be coated or painted with different finishes or colors to achieve a specific textured or patterned appearance. Overall, with the right techniques and processes, aluminum sheets can be transformed and customized to have a wide range of textures and patterns.

- Q: What are the potential health risks associated with handling aluminum sheets?

- <p>Working with aluminum sheets can pose certain health concerns, primarily due to inhalation of aluminum dust or fumes. Long-term exposure may lead to respiratory issues and potentially neurological problems. Aluminum dust can cause irritation to the eyes, nose, and throat. In some cases, it may contribute to the development of Alzheimer's disease, although this link is still debated. It's important to follow safety guidelines, such as using proper ventilation and wearing protective gear like masks and gloves, to minimize these risks.</p>

- Q: Can 101 aluminum sheets be used in aerospace applications?

- Yes, 101 aluminum sheets can be used in aerospace applications. 101 aluminum is a commonly used alloy in the aerospace industry due to its excellent strength-to-weight ratio, high corrosion resistance, and good formability. It is often used for structural components, such as aircraft skins, wings, and fuselage panels. Additionally, 101 aluminum sheets can be easily machined and welded, making them ideal for aerospace applications where precision and durability are crucial.

- Q: Can aluminum sheets be easily formed into different shapes?

- Yes, aluminum sheets can be easily formed into different shapes due to their malleability and ability to be bent, molded, and shaped without cracking or breaking.

- Q: Is it possible to use aluminum sheets for indoor purposes?

- <p>Yes, aluminum sheets can be used for indoor applications. They are commonly used in interior design for their durability, lightweight, and resistance to corrosion. Aluminum sheets are often utilized in the construction of furniture, decorative panels, and even as a material for interior walls and ceilings. Their ease of maintenance and ability to be recycled make them an environmentally friendly option for indoor use.</p>

- Q: I would like to use an alloy of copper often called aluminum bronze or aluminum brass for making wire wrapped jewelry but I am unable to find a supplier. An alloy that has no zinc or lead would be best to avoid toxicity problems. This alloy should be principally copper and aluminum but other added materials would be acceptable if not toxic. Nickel, silicon, manganese, and iron are sometimes added to increase performance of the alloy and should be acceptable (no lead or zinc please). The material obviously needs to be bendable enough to work with wire wrapping so if it is brittle it will not work. It should then be at least as usable as aluminum, copper, or stainless steel wire.

- My lady I nonetheless use it to cook dinner my hams and turkeys and to store meals in the frig, however its fitting a dinosaur and its on its last leg and there may be so many different matters now we can use but up to now years it had its use but science and Tech. Has come and made it out of date. However still I like to apply it to ocassions

- Q: What are the different types of protective films available for aluminum sheets?

- There are several types of protective films available for aluminum sheets, including adhesive-backed films, peelable films, electrostatic films, and spray-on films. These films provide temporary protection against scratches, abrasions, and other damage during transportation, storage, and fabrication processes.

- Q: This question asks for the various dimensions in which aluminum sheets can be obtained.

- <p>Aluminum sheets are available in a variety of sizes depending on the manufacturer and the specific application. Common sizes include 12x12 inches, 24x24 inches, 4x8 feet, and 4x10 feet. Thickness can range from 0.010 inches (0.25 mm) for thin sheets to 0.5 inches (12.7 mm) for thicker plates. Custom sizes can also be ordered, and the availability of these sizes may vary by supplier. It's important to check with the specific supplier for the exact sizes they offer, as options can differ.</p>

- Q: So I want to solder aluminum cans together for this project I have. What tools will I need?

- Your aluminum can's are unfortunatly too thin to solder. Your best bet for this project, is going to be a hot glue gun. Hope this helps.

- Q: Whether its strong or not, im looking to get grime like stains out of my aluminum rims. It looks like they can be worked out after time, but i dont think i want to risk acidic products because im not 100% sure if theres a clear coat (i have eagle 077s if that helps!). I have read weird ideas from buffing with baby oil to brake cleaner since its super strong but dont wanna tear up my nice new wheels! Any input is greatly appreciated

- This Site Might Help You. RE: what is the best polished aluminum wheel cleaner? Whether its strong or not, im looking to get grime like stains out of my aluminum rims. It looks like they can be worked out after time, but i dont think i want to risk acidic products because im not 100% sure if theres a clear coat (i have eagle 077s if that helps!). I have read weird ideas from...

Send your message to us

Decorative and Constructive Aluminum Honeycomb Sheets with Coated Embossed Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords