Aluminum Honeycomb Sheets Coated Aluminum Coil Sheet for Composite Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of Coated Aluminium Coil Sheet for Composite Panel

Alloy: 1050, 1100, 3003, 3005, 3105, etc

Thickness: 0.15mm~1mm

Painting Thickness: 5-10mic for back coating, 15-40mic for top coating

Paint Types: PVDF, PE, HDPE, LDPE, etc

Width: 900mm- 1950mm

Color: According to RAL colors or customer's samples

2. Application of Coated Aluminium Coil Sheet for Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Coated Aluminium Coil Sheet for Composite Panel

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

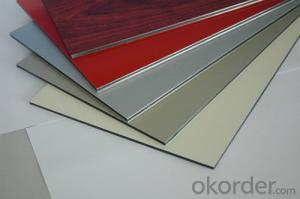

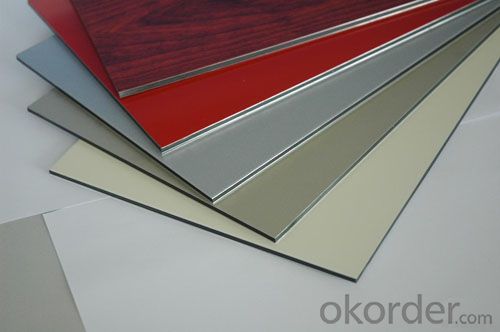

5. Image of Coated Aluminium Coil Sheet for Composite Panel

6. Package and shipping of Coated Aluminium Coil Sheet for Composite Panel

eye to Sky

eye to wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

- Q: Are aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding.

- Q: Is it possible to use aluminum sheets for constructing a sustainable building?

- <p>Yes, aluminum sheets can be used to create a sustainable building due to their recyclability, low thermal conductivity, and durability. Aluminum is a lightweight material that can reduce the energy consumption in transportation and construction. It also has a high recycled content ratio and can be easily recycled, which reduces waste. Additionally, aluminum's low thermal conductivity can contribute to energy efficiency in buildings by reducing heat transfer, thus lowering energy costs for heating and cooling. However, it's important to consider the entire life cycle of the material and ensure that the manufacturing and disposal processes align with sustainable practices.</p>

- Q: To rephrase- in our physics class we found that a simple bar magnet wouldn't attract to an aluminum gutter nail, but our teacher told us to find out whether or not any magnet could lift up the aluminum material. If you answer please give a reference or source, or at least an idea on how to go about researching this, all help appreciated, thanks and God Bless!

- Aluminum Magnet

- Q: Is it possible to use aluminum sheets in environments with high temperatures?

- <p>Yes, aluminum sheets can be used in high-temperature environments, but with certain considerations. Aluminum has a high melting point of around 660掳C (1220掳F), which allows it to withstand high temperatures. However, its mechanical properties can degrade over time when exposed to sustained high temperatures, especially above 200掳C (392掳F). For applications requiring long-term exposure to high temperatures, special heat-resistant aluminum alloys or coatings may be necessary to maintain structural integrity and performance. It's also important to consider the specific conditions and the maximum temperature the aluminum will be exposed to when determining its suitability for a high-temperature application.</p>

- Q: What is aluminium plate L2-Y2?

- L2 is the old number, the new brand corresponds to 1060, and the same Y2 is also the old number to indicate the state of the heat treatment method, the new method of expression is H24, which means semi hard state. Ji'nan Hongda Aluminium Industry Co., Ltd.

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: Can aluminum sheet be bent or formed into different shapes?

- Indeed, aluminum sheet possesses the capacity to be effortlessly bent or molded into diverse forms. As a remarkably ductile metal, aluminum can be bent, shaped, or molded without any risk of cracking or fracturing. This characteristic renders it a perfect selection for a wide array of applications where adaptability and customization are essential. Multiple techniques, including the utilization of a brake press, roll forming, or specialized bending tools, can be employed to bend aluminum sheets. The degree of bendability may vary based on the thickness and grade of the aluminum sheet. Nevertheless, in general, aluminum is renowned for its exceptional malleability and aptitude to assume various configurations.

- Q: How do you determine the thickness tolerance of an aluminum sheet?

- To determine the thickness tolerance of an aluminum sheet, several factors need to be considered. Firstly, it is important to refer to the industry standards and specifications for aluminum sheets. These standards typically provide guidelines and tolerances for various thicknesses of aluminum sheets, which can vary depending on the specific alloy and grade of the material. Next, it is crucial to use precise measuring equipment such as calipers or micrometers to accurately measure the thickness of the aluminum sheet. Multiple measurements should be taken at different locations on the sheet to account for any potential variations. Once the measurements are obtained, they should be compared to the specified thickness tolerance provided by the industry standards. The tolerance typically represents the acceptable range within which the actual thickness of the sheet can vary. For instance, if the specified thickness tolerance is ±0.002 inches, it means that the sheet's thickness can vary within this range. If the measured thickness falls within the specified tolerance range, the sheet is considered to be within tolerance. However, if the measured thickness exceeds the upper or lower limit of the tolerance range, it indicates that the sheet is out of tolerance and may not meet the required specifications. In some cases, it may be necessary to consult with the manufacturer or supplier of the aluminum sheet to determine the specific tolerance requirements for a particular application. They can provide additional information and guidance regarding the appropriate thickness tolerance to ensure the sheet meets the intended purpose. Overall, determining the thickness tolerance of an aluminum sheet involves following industry standards, using accurate measuring equipment, and comparing the measured thickness to the specified tolerance range. This helps ensure that the sheet meets the required specifications and can be used effectively in various applications.

- Q: what were the cinergy field (riverfront stadium, cincinnati, oh) seats made of? were they metal or aluminum? i know they were silver under the red paint...

- Yes, they were. Aluminum IS a metal. Aluminium is a soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray

- Q: What are the safety precautions when working with aluminum sheet?

- When working with aluminum sheet, it is important to take certain safety precautions. These include wearing personal protective equipment such as gloves, safety glasses, and a dust mask to protect against potential hazards. It is also advisable to work in a well-ventilated area to avoid inhaling any fumes or dust particles. Additionally, using appropriate tools and machinery specifically designed for handling aluminum sheets is essential to prevent accidents or injuries. Finally, proper handling and storage of aluminum sheets, ensuring they are stacked securely and avoiding any sharp edges, can help minimize the risk of accidents or damage.

Send your message to us

Aluminum Honeycomb Sheets Coated Aluminum Coil Sheet for Composite Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords