Colorful PPGI /PPGL from China Manufacturer /PPGL Steel roofing Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colorful PPGI /PPGL from China Manufacturer

1. Detailed Specifications:

| Product | PPGI Color Coated Galvanized Steel Sheet/Coloful Steel Coil |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2.Colorful PPGI /PPGL from China Manufacturer

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

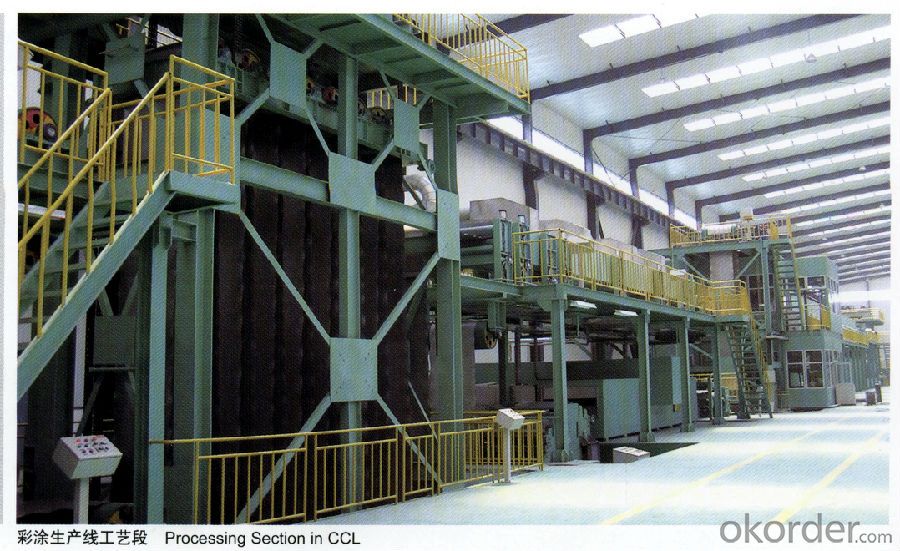

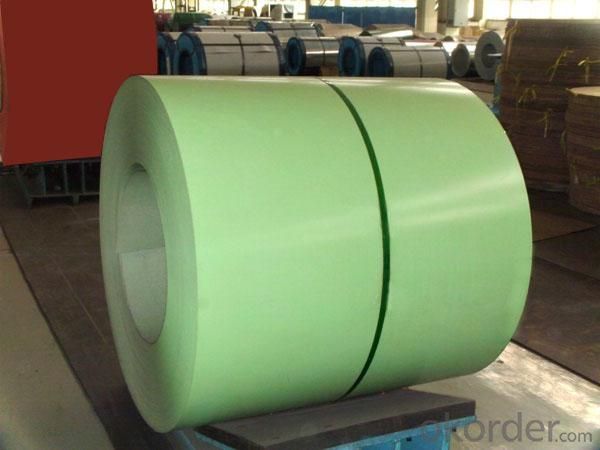

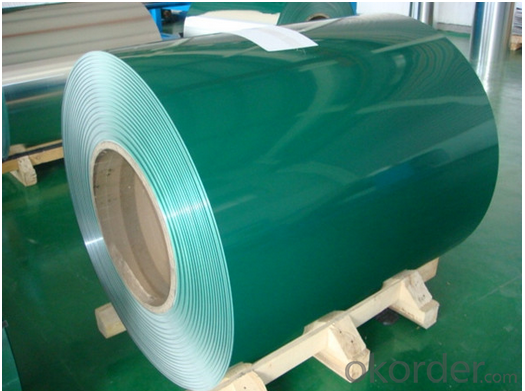

3. Colorful PPGI /PPGL from China Manufacturer

production Line:

production show:

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty:

1Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: i have purchased a high dollar Martin guitar and i was wondering if there are many people out there that have used steel string acoustics for classical and flamenco guitar playing.otherwise i will need a nylon stringeror.. uld i put nylon strings on an old yamaha steel string guitar that i have?

- Guitars built for either nylon or steel strings are constructed differently. You will have problems putting nylon strings on a steel stringed guitar and visa verse. I say NEITHER is a good idea. If I were in your shoes, I would walk on line or to a guitar store and purchase a nylon stringed guitar. That's what I did years ago and now I am hooked. I got a second hand Takamine A/E that work just fine for a couple hundred and then just a yr or so ago I got a brand new one, an EC132C and I just LOVE it. As my skills improve I plan on upgrading to a custom built acoustic only with a cutaway. I like cutaways but not the electronics. I never plug into my amp hardly at all. Yamaha makes nylon guitars too VERY cheap and real good tonal quality, I was VERY impressed with one that I played. I upgraded my tuners on my new Takamine to Schaller 16:1 and put the old Takamine tuners on that Yamaha and it's a really nice little guitar to kick around on when I am at that person's place.

- Q: i have a white spot on my stainless steel stove, its on the part behind the burners where the oven controls are, does anyone know what it may be and how to remove it. i have tried soap and water and stainless steel cleaner but neither worked. thanks!

- Baking soda mixed with liquid dish soap can make a good paste to gently rub on stains. Be sure to rinse the stainless steel surface thoroughly, and towel dry. If the stains still remain you can try vinegar. Remember to thoroughly rinse and towel dry. If stains still remain I recommend trying a stainless steel cleaner and polisher. Barkeeper's Friend is a good powder formula that can clean without scratching. Be sure to follow the directions, rinse thoroughly, and towel dry. These methods should help remove the discolorations

- Q: How are steel coils used in the production of storage racks?

- Steel coils are used in the production of storage racks as they serve as the primary raw material for manufacturing the rack components. These coils are typically cut and formed into various structural shapes, such as uprights, beams, and crossbars, which are then assembled to create the storage rack system. The strength and durability of steel make it an ideal material for supporting heavy loads, ensuring the stability and longevity of the storage racks.

- Q: Me and my cousin have been arguing about this. I said that superman is made out of steel, but he says that people just call him the man of steel because he's hard like steel. Does he have steel in his body?

- Superman okorder /

- Q: How are steel coils used in the manufacturing of steel drums?

- Steel coils are used in the manufacturing of steel drums by being cut into sheets and then formed into cylindrical shapes, which serve as the main body of the drum. These coils provide the necessary strength and durability required for holding and transporting various materials.

- Q: What is the process of pickling and oiling steel coils?

- The process of pickling and oiling steel coils involves several steps. First, the steel coils are immersed in a pickling bath containing a mixture of acids to remove any impurities, scale, and rust from the surface of the steel. This helps to improve the quality and appearance of the steel. After pickling, the coils are rinsed with water to remove any residual acid. Next, the coils are coated with a thin layer of oil. This oil acts as a protective barrier, preventing the steel from rusting or corroding during storage, transportation, and further processing. The oil also helps to enhance the surface finish of the steel. The pickled and oiled steel coils are then typically rolled or processed further according to specific requirements. This could involve additional annealing, cold rolling, or other treatments to achieve the desired properties or dimensions. Overall, the pickling and oiling process is crucial in preparing steel coils for various applications, ensuring they are clean, corrosion-resistant, and ready for further processing or use.

- Q: How are steel coils inspected for flatness?

- To ensure they meet the necessary standards, steel coils undergo a variety of methods and techniques to inspect their flatness. Trained inspectors visually examine the coil's surface for signs of waviness or unevenness, searching for visible defects like waves, buckles, or twists that could impact its flatness. Another approach involves using specialized equipment such as flatness gauges or profilometers to inspect the coil's flatness. These instruments measure the surface profile and provide detailed information about any deviations from the desired flatness. They can detect both local and overall flatness issues, offering a more precise assessment of the coil's quality. In addition to visual and instrumental inspections, physical tests can also be conducted to evaluate the flatness of steel coils. The "drape" test, for instance, involves draping the coil over a flat surface and measuring any noticeable gaps or unevenness. This test quickly identifies major flatness problems. Moreover, computerized analysis and simulation techniques are gaining popularity for inspecting the flatness of steel coils. These methods utilize advanced software to analyze the coil's surface data and generate comprehensive reports on its flatness characteristics. By comparing the actual surface profile with the desired specifications, these techniques provide a thorough assessment of the coil's flatness. Overall, the inspection of steel coils for flatness combines visual inspection, specialized equipment, physical tests, and advanced analysis techniques. These methods ensure that the coils meet the necessary flatness standards, which is essential for their successful application in industries such as automotive, construction, and manufacturing.

- Q: I need to know what steel's weakness is.

- Steel is weak to fire, fighting, and ground. Electric and water are neutral damage; everything else is resisted - assuming you're fighting a pure steel type.

- Q: How are steel coils used in the manufacturing of automotive fuel tanks?

- Steel coils are used in the manufacturing of automotive fuel tanks as they provide strength, durability, and resistance to corrosion. These coils are formed and welded into shape to create the fuel tank, ensuring it can withstand the pressure and vibrations associated with storing and transporting fuel safely.

- Q: I want a stainless steel refrigerator that doesn't leave fingerprints and I'm looking on Lowe's website but they have too many choices and i don't have a clue what they are. The have stainless, stainless look, stainless steel, monochromatic satina, and monochromatic stainless steel. Can anyone tell me what the heck those mean? lol

- Monochromatic Stainless Steel Definition

Send your message to us

Colorful PPGI /PPGL from China Manufacturer /PPGL Steel roofing Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords