Color Coated Steel Sheet or Steel Coil PPGI/PPGL

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

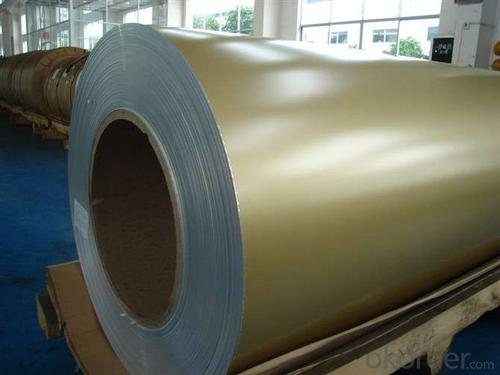

1.Structure of Color Coated GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Color Coated GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3. Color Coated GI/GL Steel Coil Images

4.Color Coated GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Color Coated GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I know that they have steel shot in smaller sized pellets....say, number 4 shot. I guess it's for waterfowl, etc.Do they make steel buckshot? If not, why not? Would the pellets be too heavy? Wouldn't they have excellent penetration ability?

- Steel shot is used for hunting migratory waterfoul. Since buckshot is inappropriate for waterfoul hunting , it is not manufactured. Steel is less dense than lead and for the purposes for which buckshot is appropriate, lead is permissable and is more efective. There is no need for steel buckshot.

- Q: benchmade mpr with m390 steel knife. Is it better than d2 s30v or 154cm steel?

- well first of all u hav 2 get a mpR490 STEEL STOOLMADE

- Q: i was thinking like getting a a steel building for 2 or 3 stall does anyone know how much that would cost? Have anyone used steel building how do you like them etc

- a great style of human beings are putting up those steel homes made by making use of agencies like Cleary or Morton because of the fact they are greater fee effective. yet in my opinion, i don't think of they greater wholesome horses all right. They dent very relatively, all the horse has to do is lean against it somewhat. additionally they provide no insulation so as that they are like little ovens interior the summertime and are fairly chilly interior the wintry climate. in case you're able to have adequate money it, i might flow with a competent previous formed timber barn.

- Q: How do steel coils contribute to the HVAC industry?

- The HVAC industry relies heavily on steel coils, which play a critical role in the functioning and efficiency of HVAC systems. These coils, often made from high-quality steel like stainless steel or galvanized steel, ensure durability and resist corrosion. One way steel coils contribute to the HVAC industry is by facilitating heat transfer. HVAC systems use coils to transfer heat between the air and a refrigerant. For instance, in air conditioning units, the evaporator coil absorbs heat from the indoor air, while the condenser coil releases heat to the outside air. The steel coils in these units provide a large surface area for efficient heat exchange, allowing for effective cooling or heating of the air. Furthermore, steel coils contribute to the energy efficiency of HVAC systems. By maximizing heat transfer, these coils enable HVAC systems to operate at optimal performance levels while consuming less energy. This not only reduces energy costs for users but also makes HVAC systems more environmentally friendly by minimizing energy consumption and greenhouse gas emissions. Steel coils in HVAC systems also play a role in maintaining indoor air quality. As air passes over the coils, impurities like dust, dirt, or mold can accumulate on the coil's surface. Regular maintenance and cleaning of the coils are essential to prevent the buildup of contaminants that could negatively impact air quality. Properly maintained steel coils ensure clean and healthy indoor air, which is particularly important for commercial buildings, hospitals, and other spaces where air quality is crucial. Additionally, steel coils provide durability and longevity to HVAC systems. Steel is a strong and resilient material that can withstand high temperatures, pressure, and environmental stress. By using steel coils, HVAC systems can operate reliably and efficiently for extended periods, reducing the need for frequent repairs or replacements. Overall, steel coils are indispensable to the HVAC industry. They enable efficient heat transfer, enhance energy efficiency, improve indoor air quality, and provide durability to HVAC systems. Without steel coils, HVAC systems would significantly lose their performance and effectiveness, highlighting the vital role of steel coils in the HVAC industry.

- Q: What are the common coil thickness and width combinations available for steel coils?

- The specific requirements and standards of the industry can cause the available combinations for steel coil thickness and width to vary. Nonetheless, there are commonly used combinations that can be found. There is a range of options for coil thickness, varying from thin to thick coils. Thin coils typically have a thickness of 0.4mm to 3.0mm, while medium thickness coils can be around 3.0mm to 6.0mm. Thicker coils can range from 6.0mm to 25.0mm or even higher, depending on the specific application. The coil width also varies depending on the intended usage. Common options include widths of 600mm, 750mm, 900mm, 1000mm, 1200mm, 1250mm, and 1500mm. However, wider or narrower coils can also be available depending on the specific requirements of the customer or industry. Ultimately, the most suitable combination of coil thickness and width will depend on factors such as the intended application, manufacturing processes, transportation limitations, and customer preferences. It is crucial to consult with steel coil manufacturers or suppliers to determine the most appropriate options for your specific needs.

- Q: where can i get a thick sheet of steel ? and is steel bullet proff for example if you shoot a bullet on steel will that bullet bounce right off the steel ?

- Try the business-to-business yellow pages in your area. A local hardware store can also tell you who to contact. Or search steel plate or sheet metal on the internet to find a local supplier. No, sheet steel is not bullet proof, unless you get heavy plate. Depending on how thick it is, the plate will deform if hit by a high velocity bullet, but usually not enough to matter. Bullets have velocities from about 500 ft/sec up to roughly 3000 ft/sec, depending on the type of weapon used. I wouldn't try to use anything thinner than 3/4 inch. You'll have to experiment and see what it will actually stop. I can't guarantee it'll stop a high-velocity rifle slug. Try it and see.

- Q: i have recently gotten into DIY and am planning on making my own knife. My question is what kind of steel would be good to use for heat treating if i plan on using water and not oil in the process.

- Go to junkyard get old leaf spring, cut out knife, start sharpening. Why waste time heat treating steel when the spring steel as already be done.

- Q: What are the common methods of painting or coating steel coils?

- Coil coating is a commonly used technique for painting or coating steel coils. It involves cleaning and pre-treating the coils to remove contaminants and enhance adhesion. Next, a primer or base coat is applied to establish a solid foundation. This primer safeguards the steel against corrosion and enhances the overall durability of the coating. Once the primer is applied, the steel coils undergo a series of rollers to apply the topcoat. The topcoat can consist of various materials such as polyester, polyurethane, or fluoropolymer, depending on the desired properties of the final coating. These topcoats provide the desired color, gloss, and protection against weathering, chemical exposure, and UV radiation. Electrostatic spraying is another popular method for painting or coating steel coils. It involves atomizing the paint or coating material into fine droplets and charging them with electricity. The grounded steel coils attract these charged droplets, resulting in a controlled and even application of the paint or coating material. Powder coating is yet another technique utilized for painting or coating steel coils. It involves electrostatically charging a dry powder and spraying it onto the steel coils. The charged powder adheres to the steel surface due to electrostatic attraction. The coated steel coils are then heated, causing the powder to melt and form a continuous film, resulting in a durable and resistant coating. In conclusion, these methods provide a wide range of options in terms of color, finish, and performance characteristics for painting or coating steel coils. The choice of method depends on factors such as desired appearance, level of protection required, and specific application requirements.

- Q: Can steel coils be cut?

- Yes, steel coils can be cut.

- Q: What are the different methods of forming steel coils into sheets?

- There are several methods of forming steel coils into sheets, including hot rolling, cold rolling, and annealing. Hot rolling involves heating the steel coils and passing them through a series of rollers to reduce their thickness and shape them into sheets. Cold rolling, on the other hand, does not involve heating the coils and instead uses pressure to shape them into sheets, resulting in a smoother and more precise finish. Annealing is a process that involves heating the steel coils to a specific temperature and then slowly cooling them, which helps to relieve stress and improve the material's ductility before it is formed into sheets.

Send your message to us

Color Coated Steel Sheet or Steel Coil PPGI/PPGL

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords